Method for preparing amorphous silicon powder

A technology of amorphous silicon and powder, which is applied in the field of preparation of amorphous silicon powder, can solve the problems of low primary utilization rate of raw materials, high production condition requirements, a large number of by-products, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

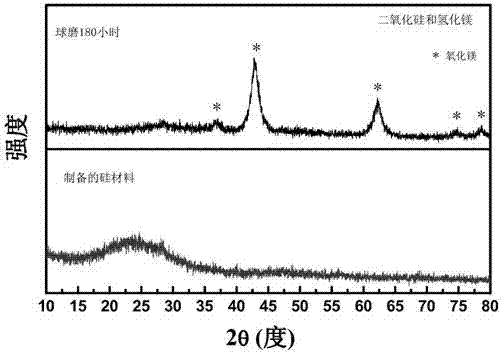

Embodiment 1

[0023] The silica powder was dried in a vacuum oven at 120 °C for 12 h. Under the protection of argon atmosphere, firstly put 0.035 mol of magnesium hydride and 0.018 mol of silicon dioxide powder into the ball milling jar respectively, then put the balls into the ball milling jar and seal it. The ratio of ball mass to material mass is 80:1. At room temperature, the ball mill tank was continuously ball milled at a speed of 500 rpm for 180 h. After taking it out, it was washed 3 times with dilute acid and ethanol, and washed with deionized water until the solution was neutral. The powder obtained by drying and cooling is amorphous silicon powder.

Embodiment 2

[0025] The silica powder was dried in a vacuum oven at 80 °C for 24 h. Under vacuum conditions, first transfer 0.03 mol of calcium hydride and 0.0125 mol of silicon dioxide to the ball mill jar, then put the balls into the ball mill jar and seal it. The ratio of ball mass to material mass is 160:1. At room temperature, the ball mill tank was continuously ball milled at 450 rpm for 220 h, and after taking it out, it was washed with dilute acid and ethanol three times, and washed with deionized water until the solution was neutral. The powder obtained by drying and cooling is amorphous silicon powder.

Embodiment 3

[0027] The silica powder was dried in a vacuum oven at 90 °C for 10 h. Under the protection of an argon atmosphere, 0.024 mol of magnesium hydride, 0.021 mol of calcium hydride and 0.018 mol of silicon dioxide were loaded into a ball mill jar, and then the balls were put into the ball mill jar and sealed. The ratio of ball mass to material mass is 200:1. At room temperature, the ball mill jar was continuously ball milled at a speed of 550 rpm for 168 h. After taking it out, it was washed 3 times with dilute acid and ethanol, and washed with deionized water until the solution was neutral. The powder obtained by drying and cooling is amorphous silicon powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com