Degradable mulching film containing plant fiber degradable filler

A technology for degrading mulch and plant fibers, which is applied in the field of ground covering film manufacturing, can solve the problems of reduced transparency, poor compatibility, and unsatisfactory effects, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

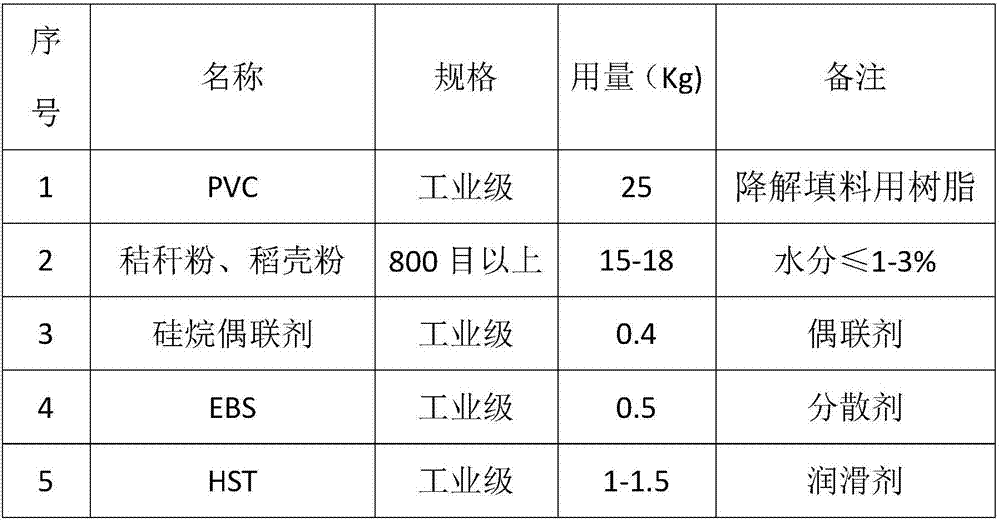

[0030] The polymer materials used to make mulch include high-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), ethylene-vinyl acetate copolymer (EVA), polyvinyl chloride (PVC), etc. In this example, polyvinyl chloride (PVC) is used to prepare the degradable mulch film. The PVC-based mulch film has softness, high transparency, air permeability (O2, CO2), suitable heat preservation, anti-fog, dust-proof, comfortable hand feeling and extension moderate advantages. At the same time, PVC resin is the most degradable polymer material among many polymers. The suspension method GS-3 resin is selected. The GS-3 resin is white powder with suitable molecular weight and good compatibility with plasticizers and stabilizers. At the same time, the raw material The source is abundant and the price is low. The particle size is 75-250um, and it is a multi-level structure model.

[0031] After adding a photodegradant, PVC macromolecules will undergo a series of complex photo...

Embodiment 2

[0070] In the natural environment, under the action of natural light, oxygen and various microorganisms, polyethylene (LDPE), linear high-density polyethylene (LLDPE), and polymer chains are broken into small molecules, and pulverized fragments appear on the appearance Brittle cracks and mechanical properties (tensile strength, elongation at break, right-angle tear strength) are significantly reduced, and even completely degraded into carbon dioxide and water and disappear, and will not cause white pollution to the soil and the environment. In order to maintain the best application effect of the mulch. This embodiment adopts the main resin formulations of three kinds of polyolefins: high-density polyethylene (LDPE), linear high-density polyethylene (LLDPE) and metallocene polyethylene (m-PE), wherein

[0071] Polyethylene LDPE: grade 2420MI=2, density d=0.921;

[0072] Linear low-density polyethylene (LLDPE): grade 7042MI = 1-2 density d = 0.918;

[0073] Metallocene polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com