Nanometer oxide-organic acid coated aluminum polyphosphate powder and preparation method thereof

A technology of nano-oxide and aluminum polyphosphate, applied in chemical instruments and methods, dyeing low-molecular organic compound treatment, inorganic pigment treatment, etc., can solve problems such as poor stability, poor performance, and difficult dispersion, and achieve easy dispersion , Strong UV absorption performance, improve anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

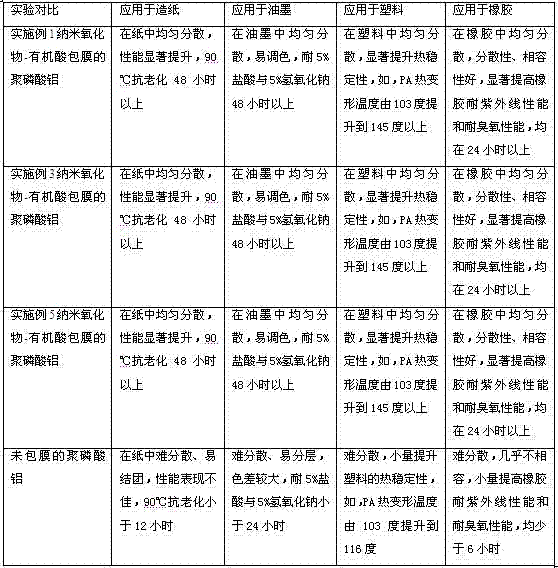

Examples

Embodiment 1

[0024] In the nano-oxide-organic acid-coated aluminum polyphosphate powder of the present invention, the mixture of aluminum metaphosphate and aluminum dipolyphosphate is the core, the mixture of MgO and CaO is the middle layer, and the nanometer-thick oleic acid and citric acid , the mixture of alkylbenzenesulfonic acid is shell, the quality of described MgO, the mixture of CaO is 0.1% of the mixture quality of aluminum metaphosphate, aluminum dipolyphosphate, and described oleic acid, citric acid, alkylbenzenesulfonic acid The mass of the acid mixture is 0.01% of the mass of the mixture of aluminum metaphosphate and aluminum dipolyphosphate.

[0025] The aluminum polyphosphate powder of nano oxide-organic acid coating of the present invention, its preparation method comprises the following steps:

[0026] Grind 100kg of the mixture of aluminum metaphosphate and aluminum dipolyphosphate, sieve, collect the mixture of aluminum polyphosphate with a particle size of 0.2 μm, add ...

Embodiment 2

[0028] In the nano oxide-organic acid-coated aluminum polyphosphate powder of the present invention, the mixture of aluminum pyrophosphate and aluminum tripolyphosphate is the nucleus, ZnO, CuO, Fe 2 o 3 The mixture of nanometer thick benzoic acid and phthalic acid is the shell, the ZnO, CuO, Fe 2 o 3 The mass of the mixture is 2% of the mass of the mixture of aluminum pyrophosphate and aluminum tripolyphosphate, and the mass of the mixture of benzoic acid and phthalic acid is 0.2% of the mass of the mixture of aluminum pyrophosphate and aluminum tripolyphosphate.

[0029] The aluminum polyphosphate powder of nano oxide-organic acid coating of the present invention, its preparation method comprises the following steps:

[0030] The mixture of 100kg of aluminum pyrophosphate and aluminum tripolyphosphate is crushed, sieved, and the aluminum polyphosphate mixture with a particle size of 5 μm is collected, and a mixture of 2kg of fatty acid amide, fatty acid metal soap and poly...

Embodiment 3

[0032] In the nano-oxide-organic acid-coated aluminum polyphosphate powder of the present invention, the mixture of aluminum polyphosphate and aluminum metaphosphate is the nucleus, and TiO 2 , MnO, Mo 2 o 3 The mixture of oxalic acid, amino acid and maleic acid in nanometer thickness is the outer shell, and the TiO 2 , MnO, Mo 2 o 3 The mass of the mixture is 10% of the mass of the mixture of aluminum polyphosphate and aluminum metaphosphate, and the mass of the mixture of oxalic acid, amino acid and maleic acid is 0.05% of the mass of the mixture of aluminum polyphosphate and aluminum metaphosphate.

[0033] The aluminum polyphosphate powder of nano oxide-organic acid coating of the present invention, its preparation method comprises the following steps:

[0034] Grind 100kg of the mixture of aluminum polyphosphate and aluminum metaphosphate, sieve, collect the mixture of aluminum polyphosphate with a particle size of 20 μm, add 6kg of fatty acid and fatty acid metal soa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com