A kind of ph response type drilling fluid aluminum-based anti-slump agent and preparation method thereof

An anti-slump agent and drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the outstanding problems affecting the anti-slump effect, reducing the ability to react with clay minerals entering the formation and the formation, and the compatibility of the drilling fluid system and other problems, to achieve the effect of improving anti-slump ability, easy industrial application, and easy control of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of aluminum-based anti-slump agent: In a 500mL three-necked bottle, pump and vent three times, pass in argon, add 30g of polyethylene glycol (number average molecular weight is 500), pump and vent three times, pass into Argon, add 30g of lactide, then add 30mg of stannous octoate, raise the temperature to 80°C, and react for 12h to obtain a polymer product. Cool the polymer product down to room temperature, add 100mL water and 90g AlCl to the polymer product 3 ·6H 2 O, lower the temperature to 10°C, and fully react for 24 hours to obtain a complex product. Adding NaOH solution with a mass concentration of 5 wt% to the complexed product to adjust the pH to 8 to obtain a neutralized product. Then, the neutralized product was heated and concentrated, dried and pulverized to obtain 180 g of a pH-responsive aluminum-based anti-slump agent.

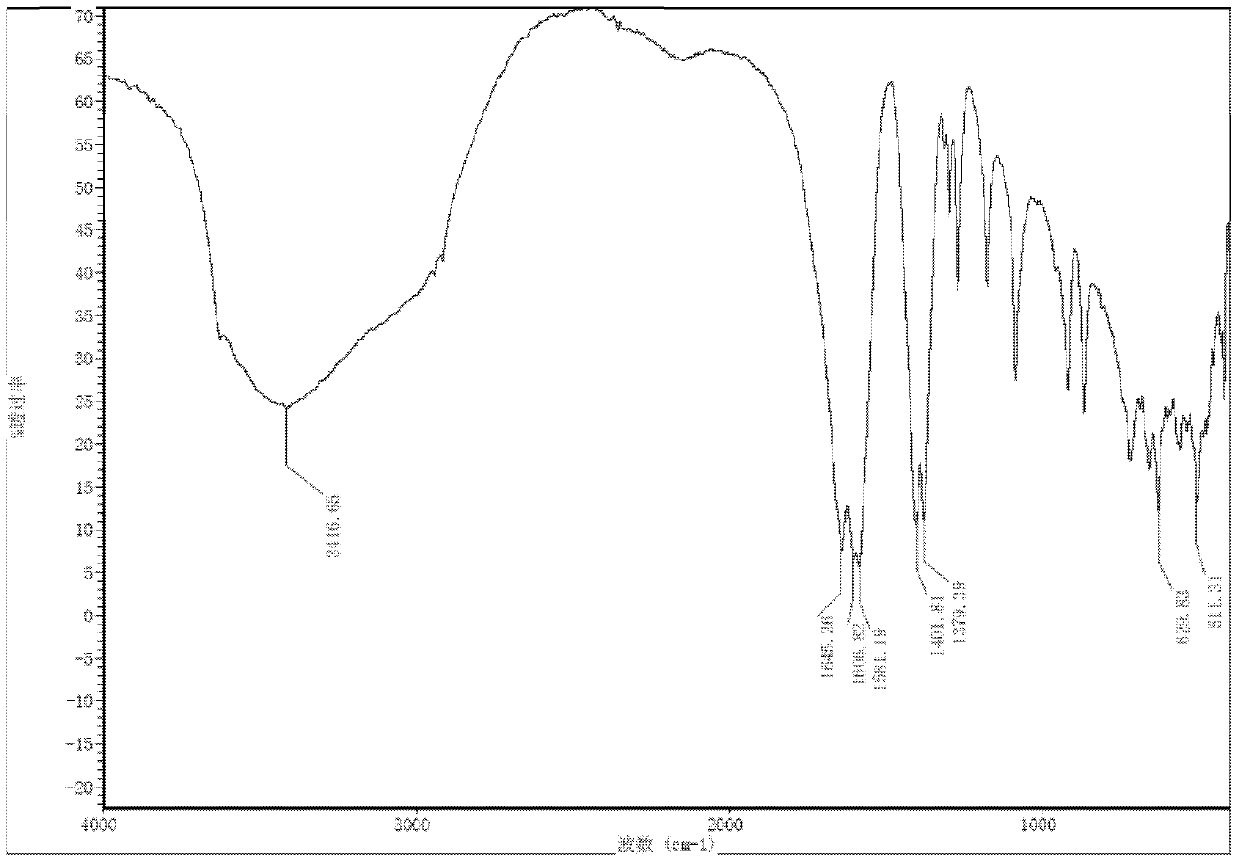

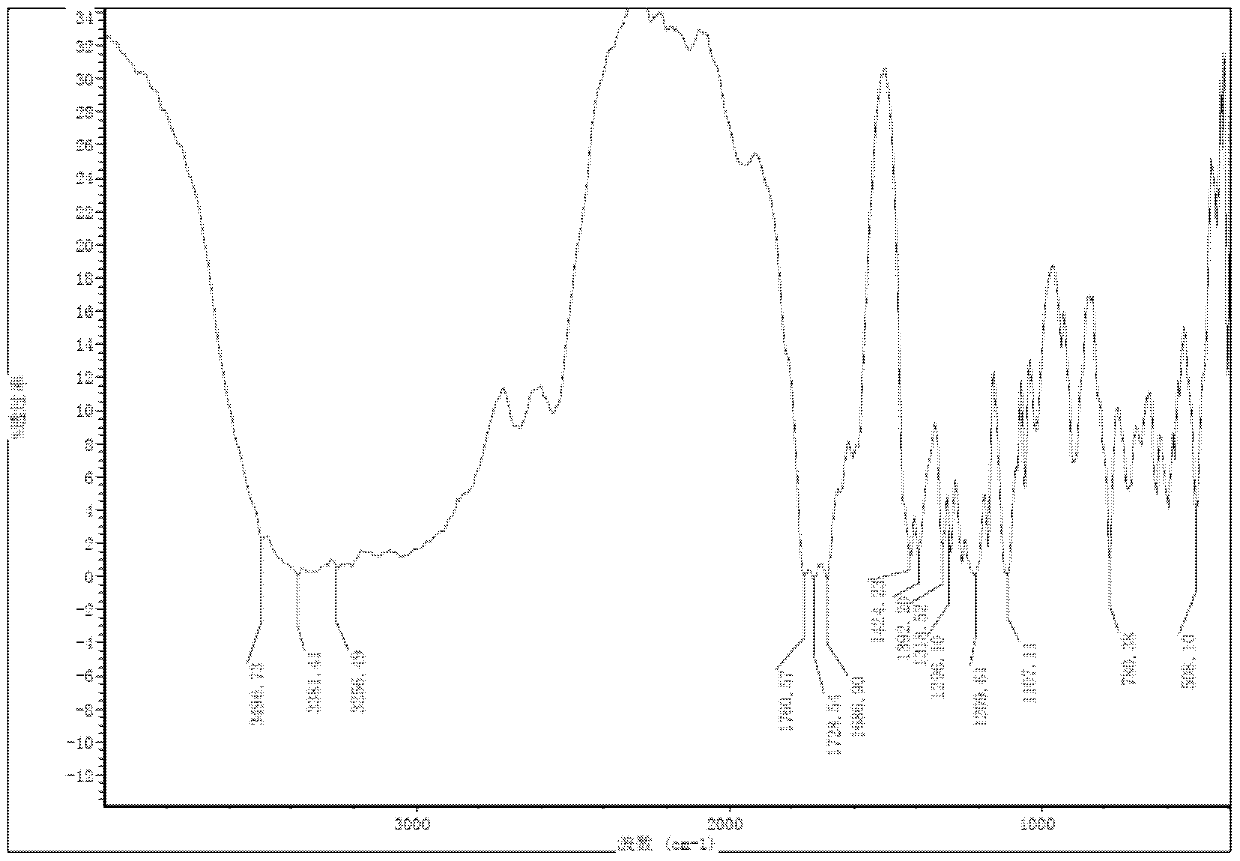

[0046] The molecular structure of the anti-slump agent sample and the intermediate product (polymerization product, ...

Embodiment 2

[0049] (1) Preparation of aluminum-based anti-slump agent: In a 1000mL three-neck bottle, pump and vent three times, pass argon, add 30g polyethylene glycol (number average molecular weight is 1000), pump and vent three times, pass into Argon, add 150g of caprolactone, then add 60mg of stannous octoate, raise the temperature to 100°C, and react for 10h to obtain a polymer product. The polymer product is cooled down to room temperature, and 250 mL of water and 240 g of Al are added to the polymer product 2 (SO 4 ) 3 16H 2 O, the temperature was raised to 100°C, and the complex reaction was fully reacted for 1 hour to obtain a complex product. A KOH solution with a mass concentration of 30 wt % was added to the complexed product to adjust the pH to 9 to obtain a neutralized product. Then the neutralized product was heated and concentrated, dried and pulverized to obtain 475 g of pH-responsive aluminum-based anti-slump agent.

[0050] (2) Evaluation of pH response performanc...

Embodiment 3

[0052] (1) Preparation of aluminum-based anti-slump agent: In a 1500mL three-necked bottle, pump and vent three times, add 30g of polyethylene glycol (number average molecular weight is 4000), pump and vent three times, feed argon, add 300g Valerolactone, then add 10 mg of stannous octoate, raise the temperature to 160°C, and react for 1 hour to obtain a polymer product. The polymer product was cooled down to room temperature, and 300 mL of water and 300 g of KAl(SO 4 ) 2 12H 2 O, the temperature was raised to 90°C, and the reaction was completed for 3 hours to obtain a complex product. Adding mass concentration to the complex product is 40wt% Na 2 CO 3 The pH of the solution was adjusted to 10 to obtain a neutralized product. Then the neutralized product was heated and concentrated, dried and pulverized to obtain 750 g of a pH-responsive aluminum-based anti-slump agent.

[0053] (2) Evaluation of pH response performance The same as in Example 1, the pH response value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com