Preparation method for NiS2/CoS2 counter electrode of dye-sensitized solar cell

A technology of solar cells and dye sensitization, applied in the field of solar cells, can solve the problems of being unsuitable for large-scale applications and expensive electrode materials, and achieve the effects of increasing catalytic active sites, improving photoelectric conversion efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

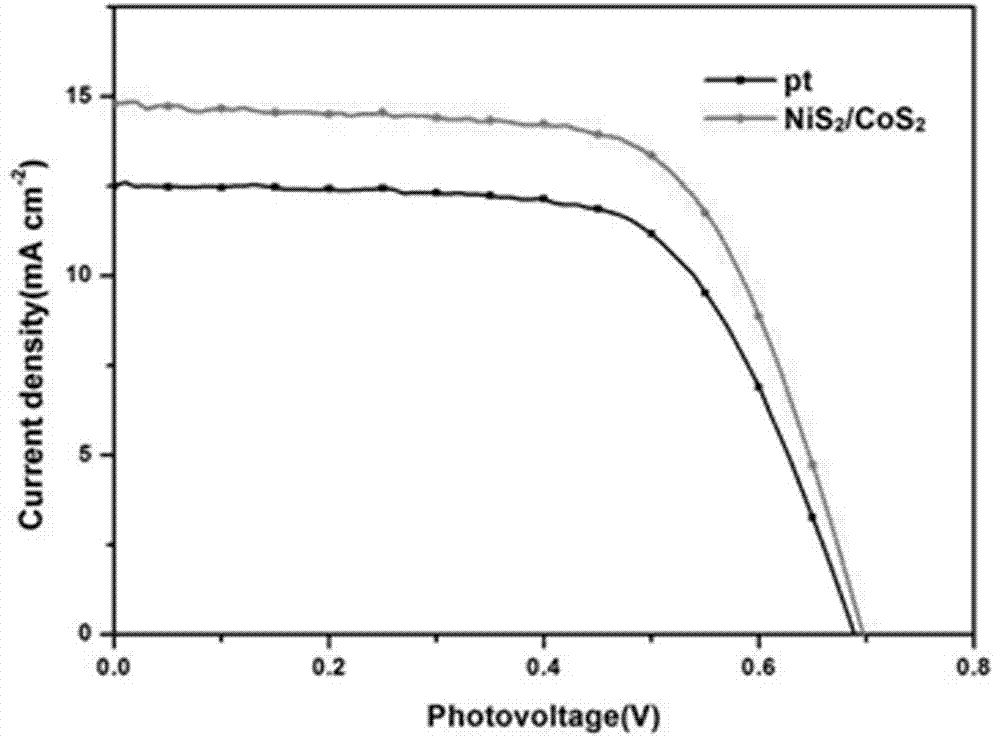

[0016] Embodiment 1 The concentration ratio of potassium persulfate and nickel sulfate is 1:1 to prepare counter electrode

[0017] Pour the mixed solution containing potassium persulfate, nickel sulfate and ammonia water (ammonia is 25%) into the glass vessel with the FTO conductive substrate, control the molar concentration of nickel sulfate in the mixed solution to be 0.4mol / L, persulfuric acid The molar concentration of potassium is 0.4mol / L, the volume ratio of ammonia water to deionized water is 1:9, let it stand for 30 minutes, take out the FTO conductive substrate, wash and dry it repeatedly with deionized water and absolute ethanol, and grow in situ on the surface of FTO Obtain the precursor; put the FTO containing the precursor into the concentration of 0.1mol / L cobalt nitrate solution and soak it for 10min, take it out and dry it; put the FTO and sulfur powder soaked in the cobalt nitrate solution into the vacuum tube furnace, the sulfur source At one end of the air...

Embodiment 2

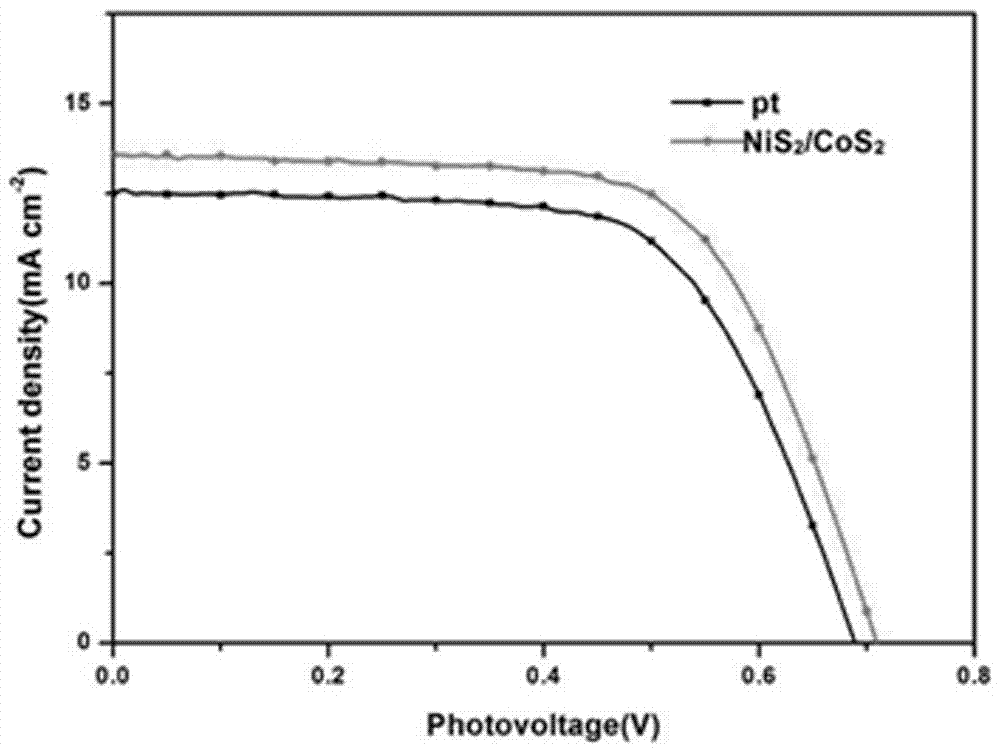

[0024] Example 2 The volume ratio of ammonia water to deionized water is 1:5 to prepare the counter electrode

[0025] Pour the mixed solution containing potassium persulfate, nickel sulfate and ammonia water (ammonia is 25%) into the glass vessel with the FTO conductive substrate, and control the molar concentration of nickel sulfate in the mixed solution to be 0.4mol / L, persulfuric acid The molar concentration of potassium is 0.4mol / L, the volume ratio of ammonia water and deionized water is 1:5, let stand for 30min, take out the FTO conductive substrate, wash and dry repeatedly with deionized water and absolute ethanol, and grow in situ on the surface of FTO Obtain the precursor; put the FTO containing the precursor into the concentration of 0.1mol / L cobalt nitrate solution and soak it for 10min, take it out and dry it; put the FTO and sulfur powder soaked in the cobalt nitrate solution into the vacuum tube furnace, the sulfur source At one end of the air vent, the molar ma...

Embodiment 3

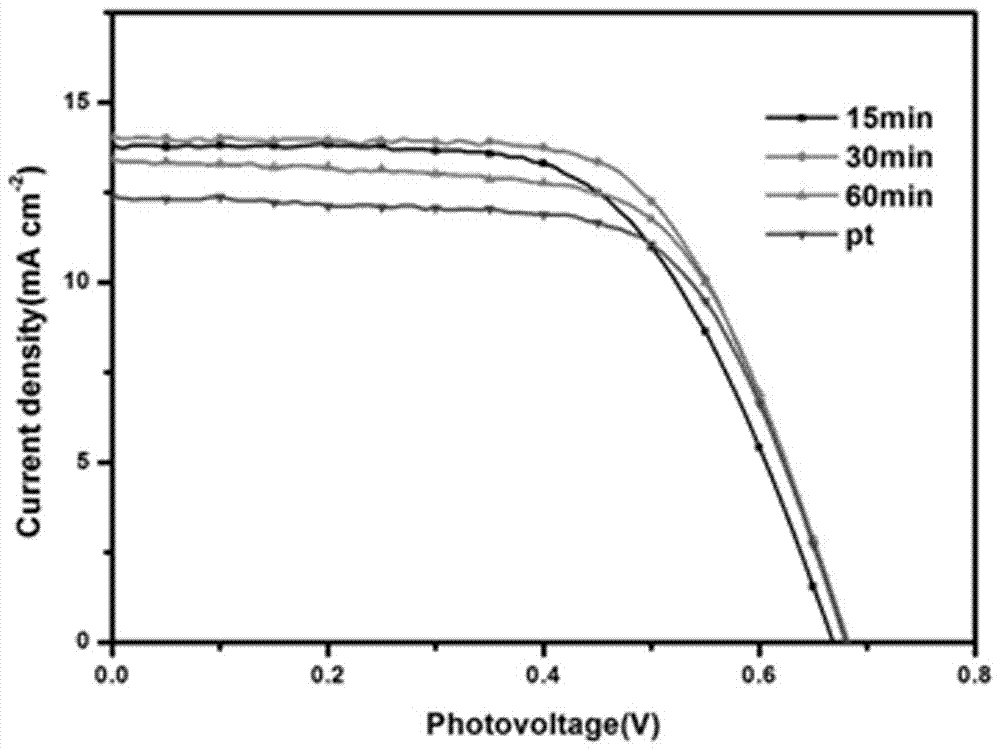

[0031] Example 3 The FTO conductive substrate was placed in a glass vessel for 15min, 30min, and 60min to prepare a counter electrode

[0032]Pour the mixed solution containing potassium persulfate, nickel sulfate and ammonia water (ammonia is 25%) into the glass vessel with the FTO conductive substrate, and control the molar concentration of nickel sulfate in the mixed solution to be 0.4mol / L, persulfuric acid The molar concentration of potassium is 0.4mol / L, the volume ratio of ammonia water to deionized water is 1:9, let it stand for 15min, 30min, 60min, take out the FTO conductive substrate, wash and dry repeatedly with deionized water and absolute ethanol, and place it in the FTO The precursor was obtained by in-situ growth on the surface; the FTO containing the precursor was soaked in a 0.1mol / L cobalt nitrate solution for 10 minutes, then taken out and dried; the FTO and sulfur powder soaked in the cobalt nitrate solution were placed in a vacuum tube furnace In the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com