Brewing method of blueberry wine

A blueberry red wine and blueberry technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, and the preparation of alcoholic beverages, can solve the problems of blueberry fruit intolerance to storage, fresh fruit easy to rot, lack of fragrance and flavor, etc. Achieve the effect of full taste, shorten production cycle and increase complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

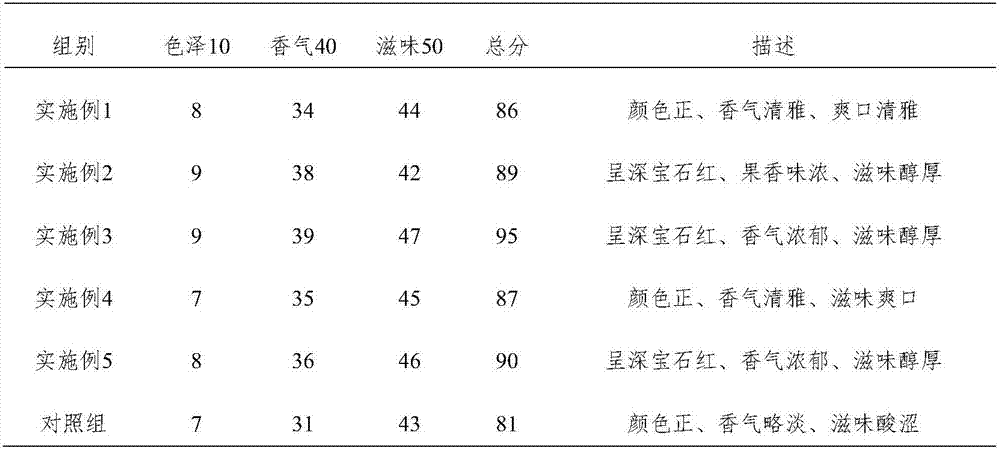

Examples

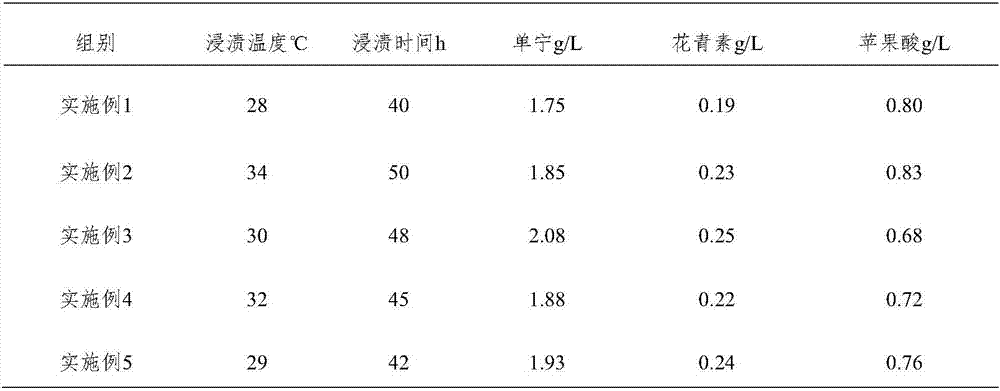

Embodiment 1

[0033] A kind of blueberry red wine brewing method comprises the following steps:

[0034] (1) Material selection: screen ripe blueberries and remove damaged and rotten ones;

[0035] (2) air-drying: adopt natural wind to carry out air-drying, until the water content of blueberry fresh fruit reduces by 20%;

[0036] (3) Cleaning: clean the air-dried blueberries and drain the moisture from the skin;

[0037] (4) Dipping: Put the cleaned blueberries into a stainless steel dipping tank, inject carbon dioxide gas from the lower part of the dipping tank, and control the temperature in the tank to 28°C for 40 hours of dipping;

[0038] (5) crushing: the dipped blueberry fruit double-roller crusher is crushed to obtain blueberry pulp;

[0039] (6) Fermentation: add 45 mg / L of sulfur dioxide to treat for 10 hours, inoculate red wine yeast, place in a fermenter for fermentation, and the fermentation temperature is 25°C;

[0040] (7) Separation: adopt centrifuge to carry out skin dre...

Embodiment 2

[0051] A kind of blueberry red wine brewing method comprises the following steps:

[0052] (1) Material selection: screen ripe blueberries and remove damaged and rotten ones;

[0053] (2) air-drying: adopt natural wind to carry out air-drying, until the water content of blueberry fresh fruit reduces by 30%;

[0054] (3) Cleaning: clean the air-dried blueberries and drain the moisture from the skin;

[0055] (4) Dipping: Put the cleaned blueberries into a stainless steel dipping tank, feed carbon dioxide gas from the bottom of the dipping tank, and control the temperature in the tank to 34°C for 50 hours of dipping;

[0056] (5) crushing: the dipped blueberry fruit double-roller crusher is crushed to obtain blueberry pulp;

[0057] (6) Fermentation: Add 55 mg / L of sulfur dioxide to treat for 14 hours, inoculate with red wine yeast, place in a fermenter for fermentation, and the fermentation temperature is 30°C;

[0058] (7) Separation: adopt centrifuge to carry out skin dreg...

Embodiment 3

[0069] A kind of blueberry red wine brewing method comprises the following steps:

[0070] (1) Material selection: screen ripe blueberries and remove damaged and rotten ones;

[0071] (2) air-drying: adopt natural wind to carry out air-drying, until the water content of blueberry fresh fruit reduces by 30%;

[0072] (3) Cleaning: clean the air-dried blueberries and drain the moisture from the skin;

[0073] (4) Dipping: Put the cleaned blueberries into a stainless steel dipping tank, inject carbon dioxide gas from the lower part of the dipping tank, and control the temperature in the tank to 30°C for 48 hours;

[0074] (5) crushing: the dipped blueberry fruit double-roller crusher is crushed to obtain blueberry pulp;

[0075] (6) Fermentation: add 50 mg / L of sulfur dioxide to treat for 12 hours, inoculate with red wine yeast, place in a fermenter for fermentation, and the fermentation temperature is 28°C;

[0076] (7) Separation: adopt centrifuge to carry out skin dregs sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com