Making method of compound instant corn paste

A production method and corn paste technology, which are applied in the food field, can solve the problems of high niacin and cannot be absorbed and utilized by the human body, and achieve the effects of prolonging the shelf life, shortening the crushing time, and improving the peeling quality and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

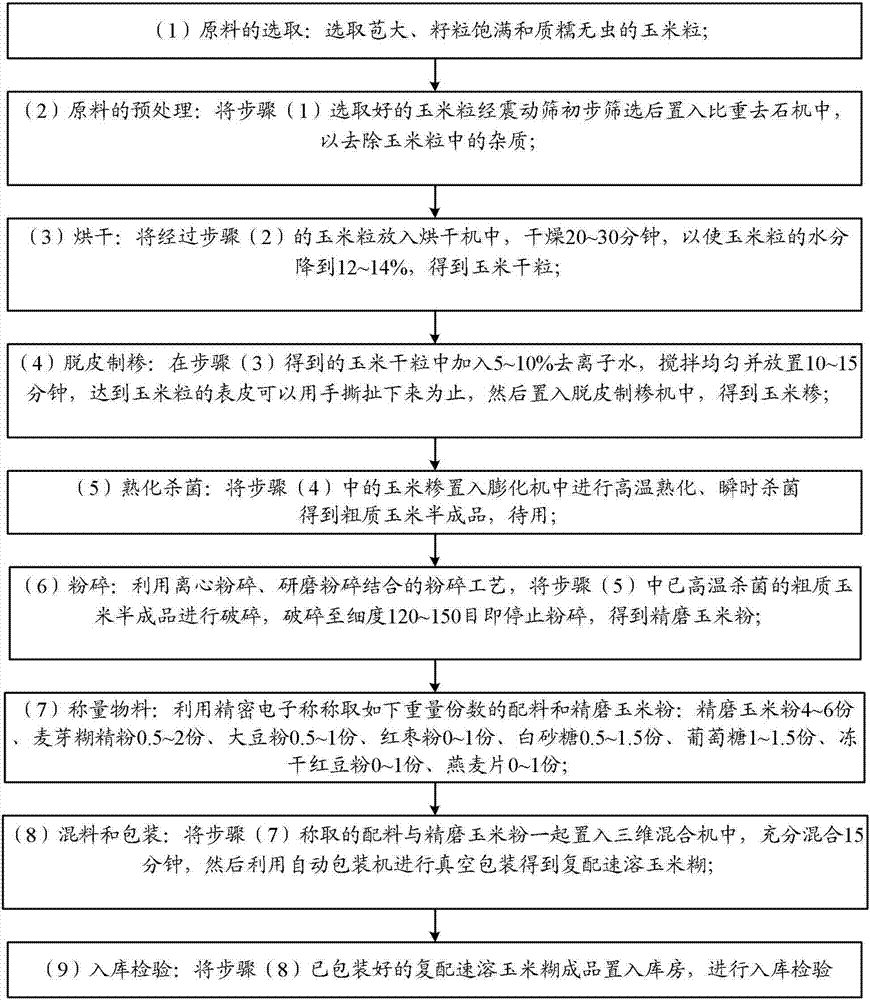

[0029] A kind of preparation method of compound instant corn paste provided by the invention comprises the following steps:

[0030] (1) Selection of raw materials: select corn kernels with large buds, full grains, waxy and insect-free;

[0031] (2) Pretreatment of raw materials: the corn kernels selected in step (1) are initially screened by a vibrating sieve and placed in a specific gravity destoner to remove impurities in the corn kernels;

[0032] (3) Drying: put the corn kernels through step (2) into a dryer, and dry them for 20-30 minutes, so that the moisture content of the corn kernels is reduced to 12-14%, so as to obtain dry corn kernels;

[0033] If the moisture content of the tested corn kernels is greater than 14%, it needs to be dried, and if the moisture content of the tested corn kernels is exactly 12-14%, it does not need to be dried.

[0034] (4) Peeling and making grits: add 5 to 10% deionized water to the dry corn grains obtained in step (3), stir evenly a...

Embodiment 2

[0051] The preparation method of another kind of composite instant corn paste provided by the invention comprises the following steps:

[0052] (1) Selection of raw materials: select corn kernels with large buds, full grains, waxy and insect-free;

[0053] (2) Pretreatment of raw materials: the corn kernels selected in step (1) are initially screened by a vibrating sieve and placed in a specific gravity destoner to remove impurities in the corn kernels;

[0054] (3) Drying: put the corn kernels through step (2) into a dryer, and dry them for 20-30 minutes, so that the moisture content of the corn kernels is reduced to 12-14%, so as to obtain dry corn kernels;

[0055] If the moisture content of the tested corn kernels is greater than 14%, it needs to be dried, and if the moisture content of the tested corn kernels is exactly 12-14%, it does not need to be dried.

[0056] (4) Peeling and making grits: add 5 to 10% deionized water to the dry corn grains obtained in step (3), st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com