A kind of fe-co-ac catalytic material and preparation method thereof

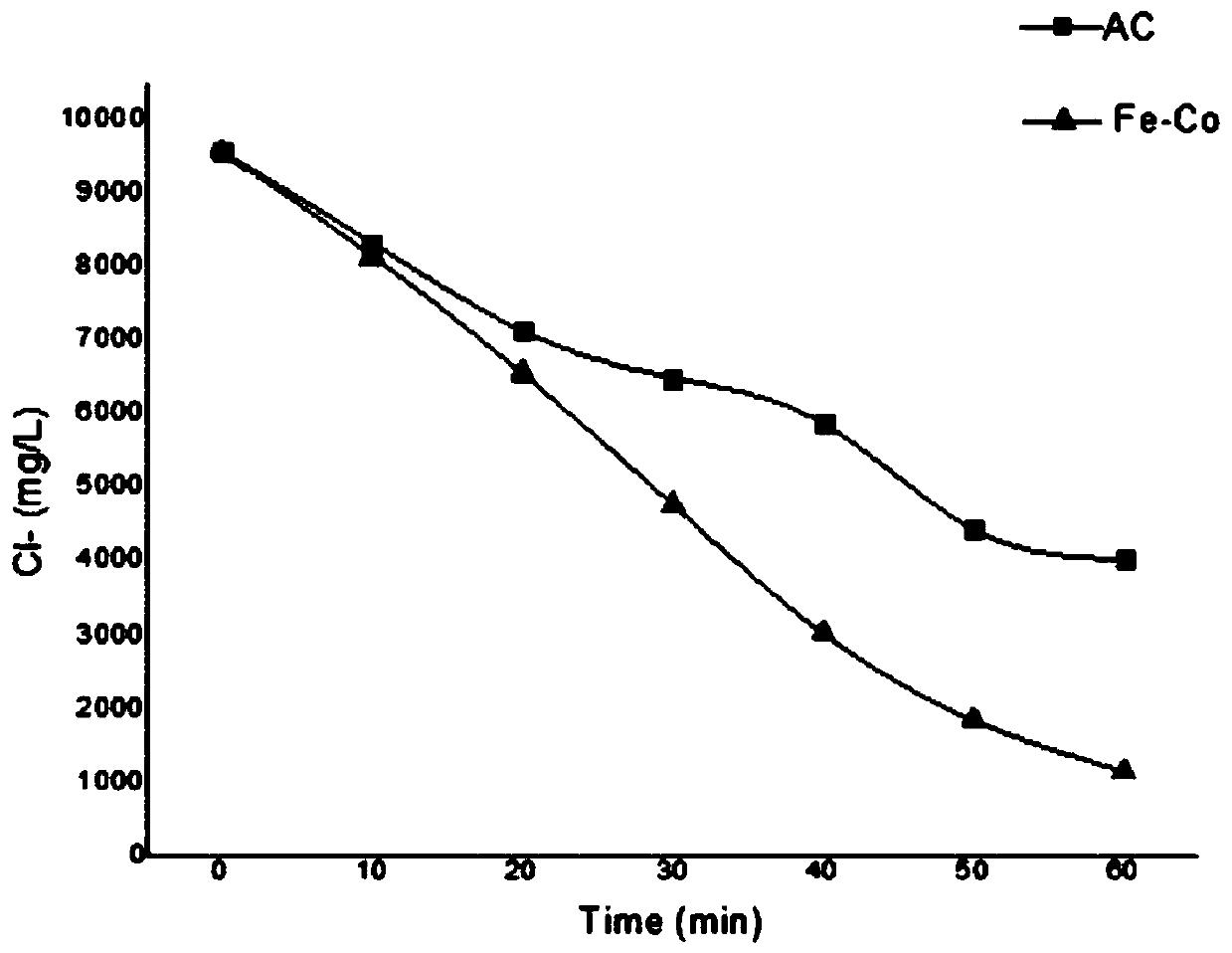

A catalytic material, fe-co-ac technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the limitations of large-scale application, impact, electrical Long adsorption time and other problems, to achieve the effect of large-scale industrial application, high chloride ion degradation rate, high electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention provides a preparation method of Fe-Co-AC catalytic material, which comprises the following steps:

[0029] S1, soak the activated carbon with an acidic aqueous solution for 12-36 h, the preferred particle size of the activated carbon is 5-100 mesh, and the acidic aqueous solution is preferably an aqueous phosphoric acid solution with a mass concentration of 15%-50%, and filter to obtain a filter cake; Washing with ionized water until the pH value is 6.5-8.5, preferably until the washing liquid after washing is neutral; placing the washed filter cake at 60-120 °C, or drying in a drying oven at 100 °C, to obtain a pre-cleaning solution. Dispose of activated carbon and set aside.

[0030]S2. Mix the pretreated activated carbon with ferric nitrate solution, cobalt nitrate solution and citric acid, and stir evenly to obtain a mixed reaction solution. The concentration molar ratio of iron and cobalt in the mixed reaction solution is 3-...

Embodiment 1

[0048] The present embodiment provides a Fe-Co-AC catalytic material, which is prepared according to the following method:

[0049] S101, soak the activated carbon with a particle size of 30 meshes in a phosphoric acid aqueous solution with a mass concentration of 40% for 40 hours, and filter the filter cake; wash the filter cake with deionized water until the pH value of the washed washing solution is 7; The filter cake was dried in a drying oven at 90°C to obtain pretreated activated carbon for use.

[0050] S102, take 20g of pretreated activated carbon, 40ml of butanol, 6.73g of Fe(NO 3 ) 3 ·9H 2 O, 4.85g of Co(NO 3 ) 2 ·6H 2 O was mixed with 2.304g (40ml 0.3M) citric acid, stirred evenly to obtain a mixed reaction solution, then added ammonia water dropwise to the mixed reaction solution to adjust the pH value of the mixed reaction solution to 6.5; After 1 h of reaction, a viscous slurry was generated.

[0051] S103. Evaporate the slurry to dryness in a 100°C consta...

Embodiment 2

[0058] The present embodiment provides a Fe-Co-AC catalytic material, which is prepared according to the following method:

[0059] S201, soak the activated carbon with a particle size of 5 meshes in a phosphoric acid aqueous solution with a mass concentration of 15% for 36 hours, and filter the filter cake; wash the filter cake with deionized water until the pH value of the washed washing solution is 6.5; The filter cake was dried in a drying oven at 120°C to obtain pretreated activated carbon for use.

[0060] S202, take 20g of pretreated activated carbon, 40ml of butanol, 8.28g of Fe(NO 3 ) 3 ·9H 2 O, 5.82g of Co(NO 3 ) 2 ·6H 2 O was mixed with 2.304g (40ml 0.3M) citric acid, stirred evenly to obtain a mixed reaction solution, then hydrazine hydrate was added dropwise to the mixed reaction solution to adjust the pH value of the mixed reaction solution to 7; The reaction was continued for 1 h, resulting in a viscous slurry.

[0061] S203, the slurry is evaporated to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com