Synthesis method of metal nanoparticle asymmetrical single-face inlayed molybdenum disulfide nanosheet

A technology of metal nanoparticles, molybdenum disulfide, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve the effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

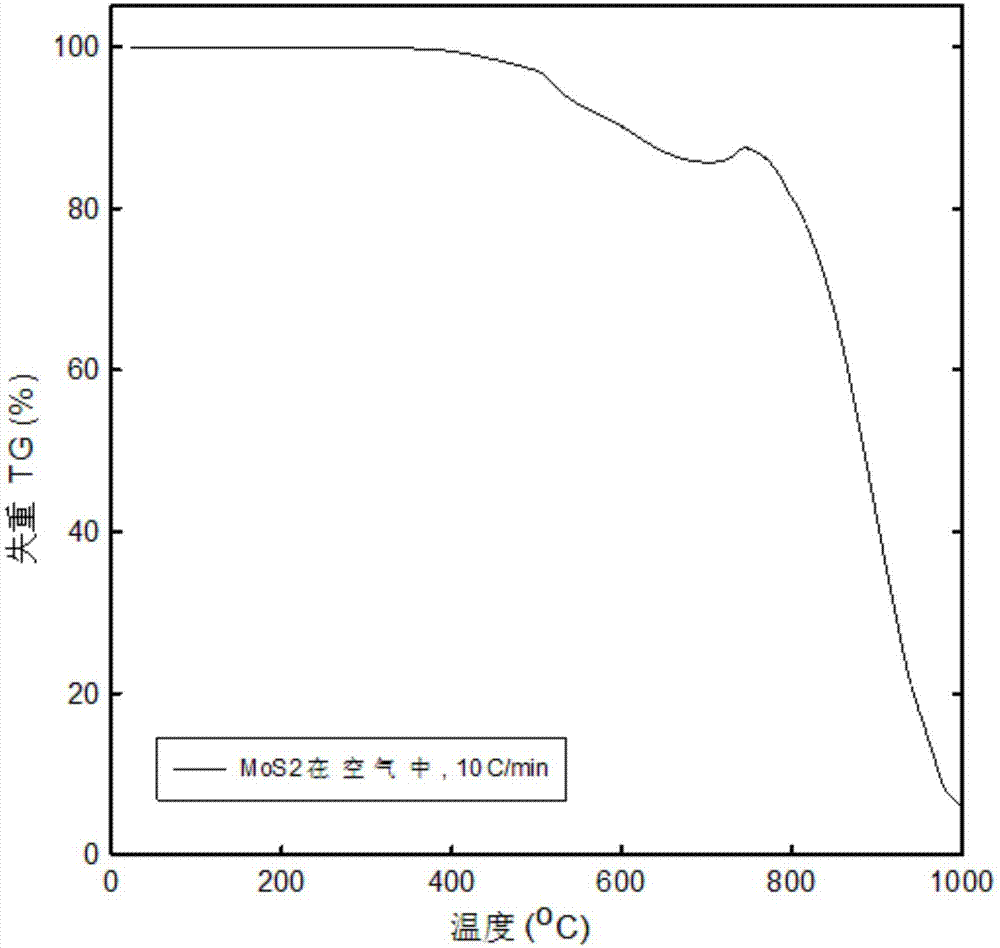

[0025] The mass ratio of platinum acetate and molybdenum disulfide powder is 1:3, the two are uniformly and fully ground in a mortar for 30 minutes, and the mixed powder solid is calcined in flowing air. After 3 hours, the metal salt was decomposed to form platinum metal nanoparticles, which were embedded on the surface of molybdenum disulfide, and cooled naturally to obtain a powder solid, which was dissolved in a round-bottomed flask containing dimethylformyl (DMF) and sonicated in a water bath. The molybdenum disulfide layered material was peeled off under the action, and finally passed through a low-speed centrifuge ~500 × g for 10 minutes to obtain the supernatant, and then passed through a high-speed centrifuge ~3000 × g for 10 minutes to separate the asymmetric single-sided metal platinum nanoparticles Inlaid molybdenum disulfide nanosheets.

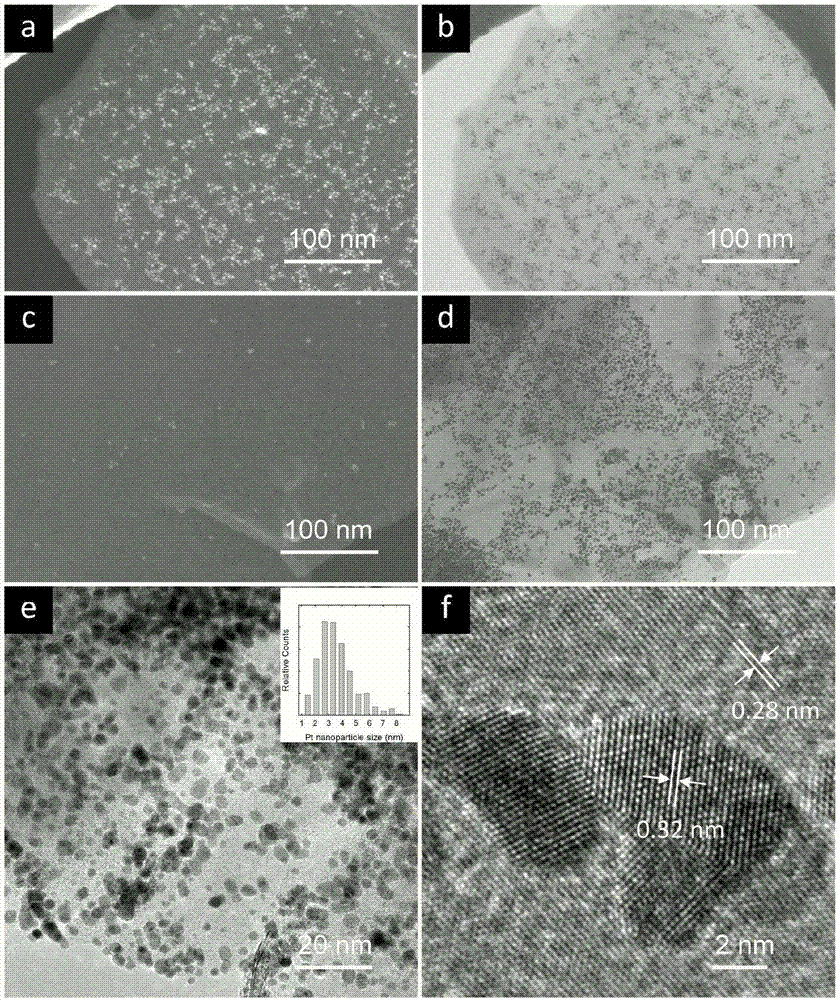

[0026] For a fixed observation area, scanning electron microscopes and transmission electron microscopes such as figure 1 As sh...

Embodiment 2

[0030] The mass ratio of platinum acetate and molybdenum disulfide powder is 1:5, the two are uniformly and fully ground in a mortar for 30 minutes, and the mixed powder solid is calcined in flowing air. After 3 hours, the metal salt was decomposed to form platinum metal nanoparticles, which were embedded on the surface of molybdenum disulfide. After natural cooling, a powder solid was obtained, which was dissolved in a round-bottomed flask containing DMF, and the molybdenum disulfide layer was peeled off under the action of ultrasonic waves in a water bath. Finally, the supernatant was obtained by a low-speed centrifuge at ~500 × g for 10 minutes, and then passed through a high-speed centrifuge at ~3000 × g for 10 minutes to separate the metal platinum nanoparticles asymmetric single-sided inlaid molybdenum disulfide nanosheets.

[0031] For a fixed observation area, scanning electron microscopes and transmission electron microscopes such as figure 1 As shown in c and d, plat...

Embodiment 3

[0033] The mass ratio of platinum acetate and molybdenum disulfide powder is 1:15, the two are uniformly and fully ground in a mortar for 30 minutes, and the mixed powder solid is calcined in flowing air. After 3 hours, the metal salt was decomposed to form platinum metal nanoparticles, which were embedded on the surface of molybdenum disulfide. After natural cooling, a powder solid was obtained, which was dissolved in a round-bottomed flask containing DMF, and the molybdenum disulfide layer was peeled off under the action of ultrasonic waves in a water bath. Finally, the supernatant was obtained by a low-speed centrifuge at ~500 × g for 10 minutes, and then passed through a high-speed centrifuge at ~3000 × g for 10 minutes to separate the metal platinum nanoparticles asymmetric single-sided inlaid molybdenum disulfide nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com