Preparation method of fluorane dye for thermal-sensitive printing

A fluorane dye, thermal printing technology, applied in the field of thermal dyes, to achieve the effect of high conversion rate, convenient for large-scale industrial production, and strong color rendering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

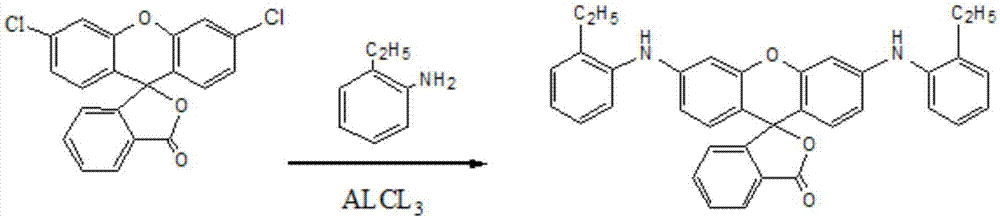

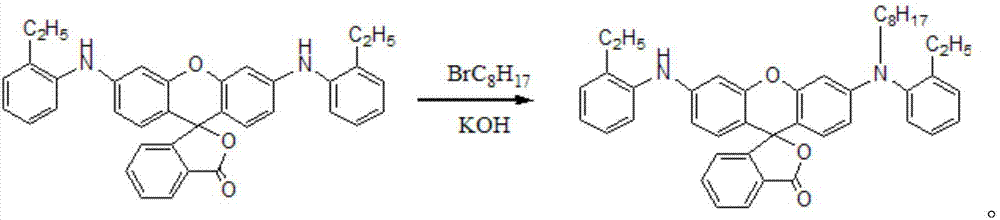

Examples

Embodiment 1

[0027] In this embodiment, the preparation method of fluoran dyes for thermal printing, the specific steps are as follows:

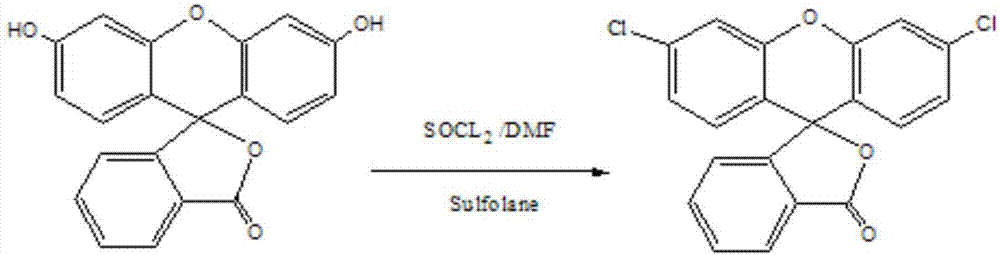

[0028] 1, the synthesis of intermediate A, its reaction formula is as follows:

[0029]

[0030] Add 50g (0.15mol) fluorescein (C 20 h 12 o 5 ), 1.46g (0.02mol) dimethylformamide (DMF) and 200ml sulfolane (C 4 h 8 o 2 S), was added to a 500ml reactor, stirred and heated to 60°C, and 70.8g (0.60mol) of thionyl chloride (SOCl 2 ), the dropwise addition is completed in about 30 minutes, continue to heat up to 80°C, keep warm for 2 hours, and the reaction is completed, cool it to about 30°C, then pour it into 250ml of acetone and water mixture with a volume ratio of 1:1, stir and precipitate After 2 hours of filtration, the filter cake was rinsed with 50ml of acetone and water mixed solution with a volume ratio of 1:1, and dried to obtain 50g of light yellow intermediate A with a yield of 90.5wt% and a content of about 96.5wt%.

[0031] The spectru...

Embodiment 2

[0047] The difference from Example 1 is that in this example, the preparation method of fluoran dyes for thermal printing, the specific steps are as follows:

[0048] (1) In the reaction bottle, add 50g (0.15mol) fluorescein (C 20 h 12 o 5 ), 2.09g (0.03mol) DMF and 300ml sulfolane (C 4 h 8 o 2 S), stirring and heating to 60 ° C, dropwise added 106.2g (0.90mol) thionyl chloride (SOCl 2 ), the dropwise addition is completed in about 30 minutes, continue to heat up to 100°C, keep the temperature for 4 hours, and the reaction is completed, cool it to about 30°C, then pour it into 250ml of acetone and water mixture with a volume ratio of 1:1, stir and precipitate After 3 hours of filtration, the filter cake was rinsed with 70ml of acetone and water mixed solution with a volume ratio of 1:1, and dried to obtain a light yellow solid, 48.1g of 3,6-dichlorofluorane, with a yield of 86.90wt%. The content is about 98.4wt%.

[0049] (2) In the reactor, add 100ml DMF, 36.9g (0.10mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com