Low-temperature inorganic composite phase-change thermal energy storage material and preparation method thereof

A phase-change heat storage material and inorganic composite technology, which are applied in the field of low-temperature inorganic composite phase-change heat storage materials and their preparation, can solve the problems of low density of graphene aerogel, harsh preparation conditions, difficult industrialization, etc. Cyclic stability, low preparation cost, and shape-controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

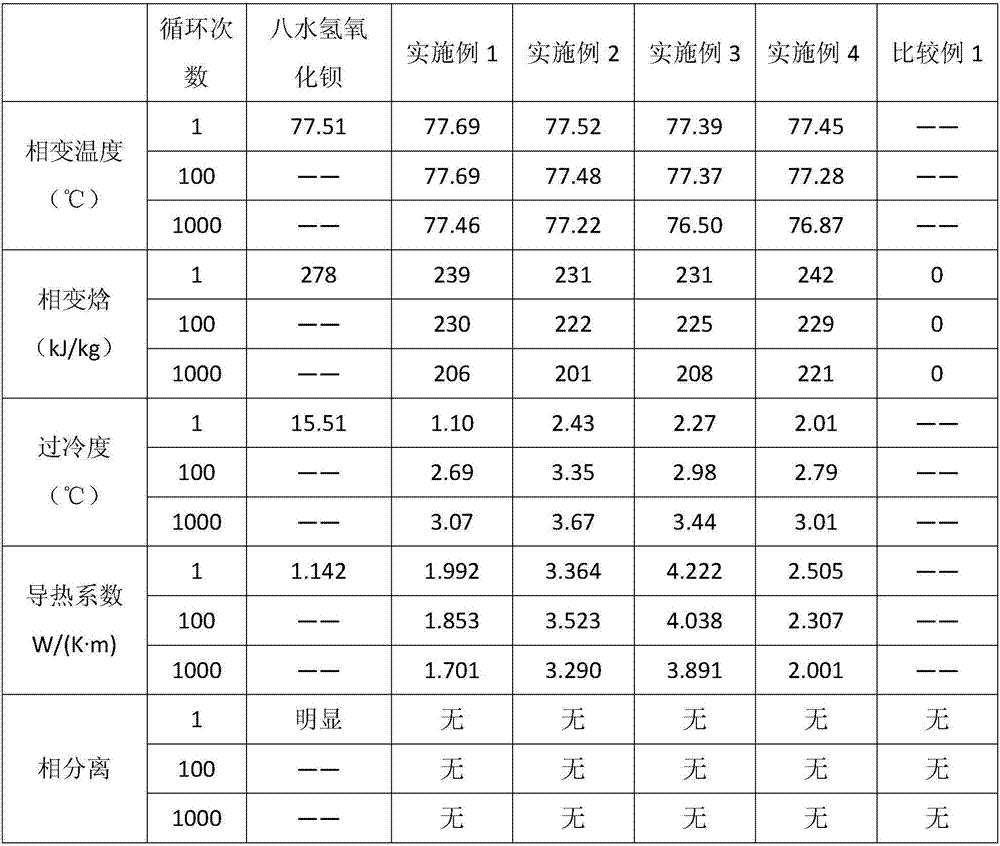

Embodiment 1

[0032] A method for preparing a low-temperature inorganic composite phase-change heat storage material, comprising the following steps:

[0033] 1) Add 0.5g of emulsifier OP‐10 to 1000g of absolute ethanol, shake well, add 1.884g of expanded graphite with a size of 50 mesh, control the temperature of the water bath at 50°C, and ultrasonically treat for 1 hour to obtain a uniform expanded graphite dispersion. Heating at 90°C, evaporating the absolute ethanol in the expanded graphite dispersion to constant weight to obtain hydrophilic expanded graphite;

[0034]2) select diameter to be 4cm, be high to be the stainless steel mold of 1.5cm, the hydrophilic expanded graphite that step 1 obtains is pressed into volume in this mold and be 18.84cm 3 Cylindrical block, based on the mass of the initial expanded graphite, the block has a density of 100kg / m 3 .

[0035] 3) Weigh 50g of barium hydroxide octahydrate, place it in a closed stainless steel container, and heat it to a molten ...

Embodiment 2

[0038] A method for preparing a low-temperature inorganic composite phase-change heat storage material, comprising the following steps:

[0039] 1) Add 1g of emulsifier OP‐10 to 2000g of absolute ethanol, shake well, add 3.768g of expanded graphite with a size of 100 mesh, control the temperature of the water bath at 50°C, and ultrasonicate for 1 hour to obtain a uniform dispersion of expanded graphite. Heating at 90°C, evaporating the absolute ethanol in the expanded graphite dispersion to constant weight to obtain hydrophilic expanded graphite;

[0040] 2) select diameter to be 4cm, be high to be the stainless steel mold of 1.5cm, the hydrophilic expanded graphite that step 1 obtains is pressed into volume in this mold and be 18.84cm 3 Cylindrical block, based on the mass of the initial expanded graphite, the block has a density of 200kg / m 3 .

[0041] 3) Weigh 80g of barium hydroxide octahydrate, place it in a closed stainless steel container, and heat it to a molten stat...

Embodiment 3

[0044] A method for preparing a low-temperature inorganic composite phase-change heat storage material, comprising the following steps:

[0045] 1) Add 2g of emulsifier OP‐10 to 2000g of absolute ethanol, shake well, add 5.652g of expanded graphite with a size of 200 mesh, control the temperature of the water bath at 50°C, and ultrasonicate for 1 hour to obtain a uniform dispersion of expanded graphite. Heating at 90°C, evaporating the absolute ethanol in the expanded graphite dispersion to constant weight to obtain hydrophilic expanded graphite;

[0046] 2) select diameter to be 4cm, be high to be the stainless steel mold of 1.5cm, the hydrophilic expanded graphite that step 1 obtains is pressed into volume in this mold and be 18.84cm 3 Cylindrical block, based on the original expanded graphite mass, the density of the block is 300kg / m 3 .

[0047] 3) Weigh 100g of barium hydroxide octahydrate, place it in a closed stainless steel container, and heat it to a molten state at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap