Modified oil sludge clean fuel and preparation method of modified oil sludge clean fuel

A technology of clean fuel and modified oil, applied in the field of petroleum sludge treatment, can solve the problems that the sludge cannot be fully contacted with air, the sludge cannot be reused, and the combustion calorific value of the sludge is low, so as to achieve high forming rate and increase forming rate. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

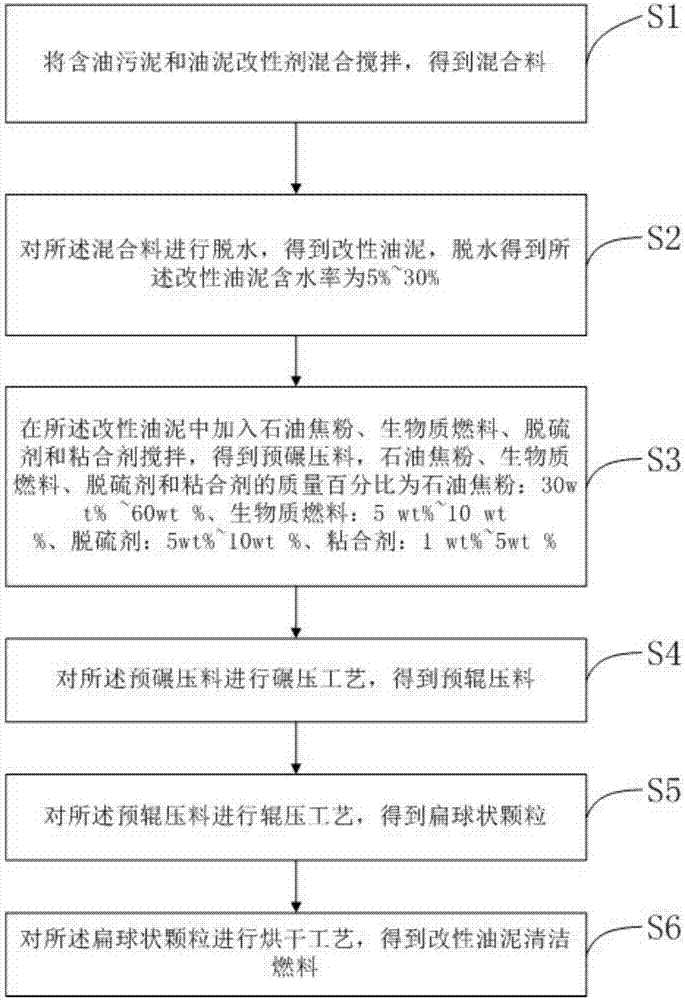

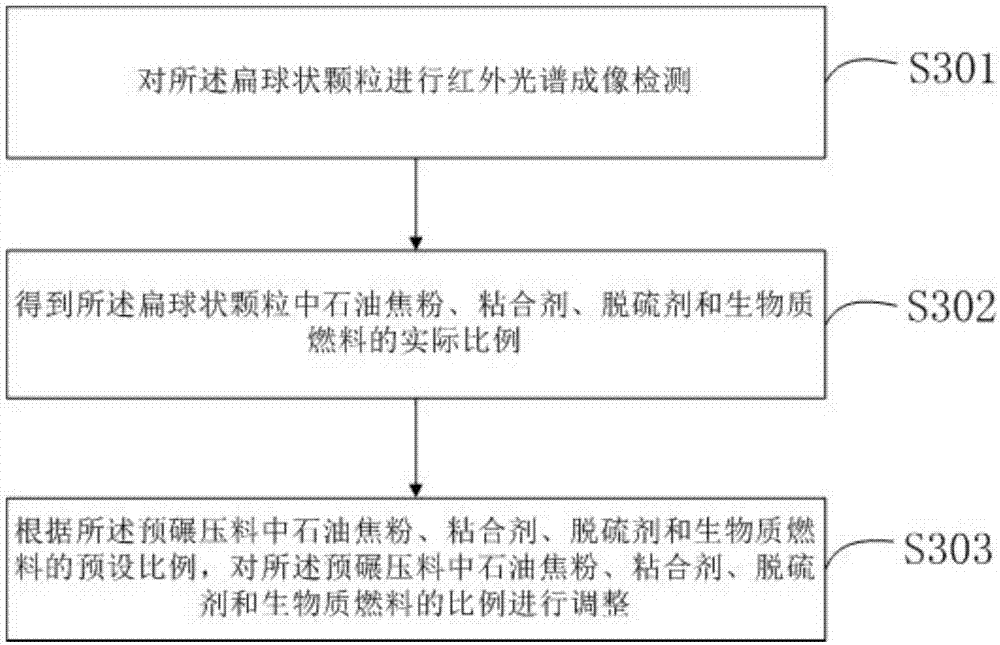

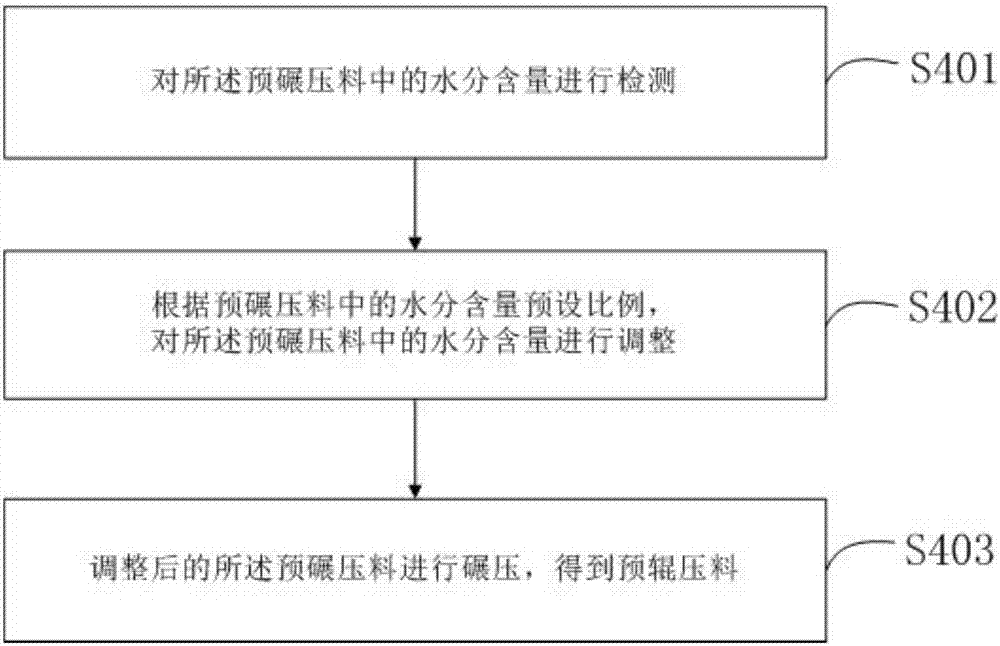

[0036] see figure 1 , figure 2 and image 3 , the preparation method of the modified sludge clean fuel provided by the embodiment of the present application comprises the following steps:

[0037] Step S1, mixing and stirring the oily sludge and the oil sludge modifier to obtain a mixture;

[0038] Step S2, dehydrating the mixture to obtain modified oil sludge, and dehydrating to obtain the modified oil sludge with a moisture content of 5% to 30%;

[0039] Step S3, adding petroleum coke powder, biomass fuel, desulfurizer and binder to the modified oil sludge and stirring to obtain a pre-rolled material, the mass percentage of petroleum coke powder, biomass fuel, desulfurizer and binder Petroleum coke powder: 30wt%~60wt%, biomass fuel: 5wt%~10wt%, desulfurizer: 5wt%~10wt%, binder: 1wt%~5wt%;

[0040] Step S4, performing a rolling process on the pre-rolled compact to obtain a pre-rolled compact;

[0041] Step S5, performing a rolling process on the pre-rolled material to o...

Embodiment 1

[0046]Oily sludge modification: Mix and stir oily sludge with a water content of 60% and a modifier, specifically: mix and stir oily sludge with a water content of 60% and an oily sludge modifier to obtain a mixture, and the oily sludge accounts for the modified The mass percentage of oil sludge is 70wt%, and the mass percentage of the oil sludge modifier in the modified oil sludge is 30wt%.

[0047] Among them, the oil sludge modifier is used to change the component structure of the oily sludge and reduce the activation energy. When the modified sludge clean fuel is burned, the sludge modifier plays a role in eliminating smoke.

[0048] The oil sludge with moisture content is directly mixed with the oil sludge modifier to make the modified oil sludge. The modification process is that the petroleum components in the oil sludge are polymerized to cause new groups in the flame retardant long-chain compounds such as asphaltene and colloid. Reduce the activation energy and convert...

Embodiment 2

[0063] Oily sludge modification: Mix and stir oily sludge with a water content of 90% and a modifier, specifically: mix and stir oily sludge with a water content of 90% and an oily sludge modifier to obtain a mixture, and the oily sludge accounts for the modified The mass percentage of oil sludge is 90wt%, and the mass percentage of the oil sludge modifier in the modified oil sludge is 10wt%.

[0064] Dehydration, the mixture is dehydrated to obtain modified oil sludge, and the moisture content of the modified oil sludge obtained by dehydration is 30%. The water content of the oily sludge in the mixture is 90%, and the oily sludge with a water content of 90% and the oil sludge modifier are mixed and stirred to obtain a mixture, the mixture includes the oily sludge and the modifier, and the oily sludge The water content of the mixture is 90%, and the mixture is dehydrated to obtain the modified oil sludge with a water content of 30%, and the modified oil sludge after dehydratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com