Preparation method and quality detection method of coxtex moutan formula granules

A technology of formula granules and Moutan bark, which is applied in the direction of medical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., to achieve uniform quality, high degree of automation, and remarkable curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

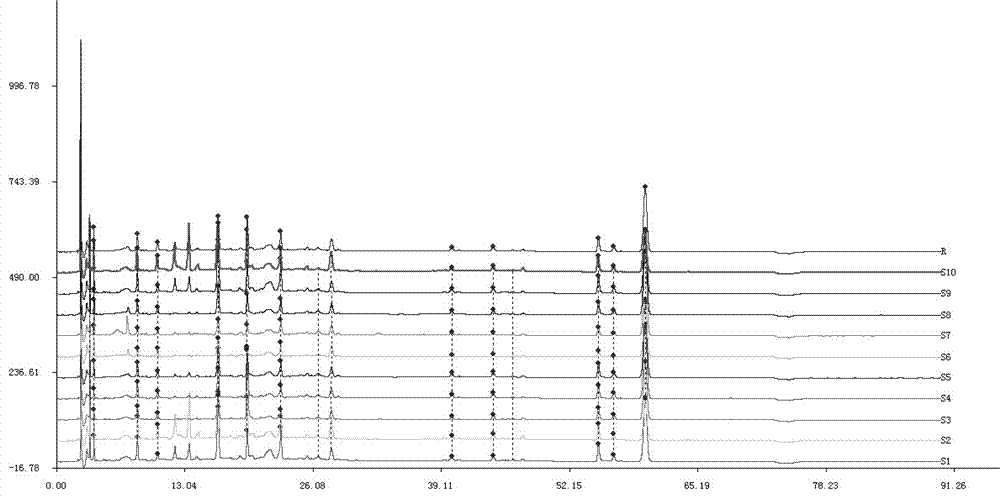

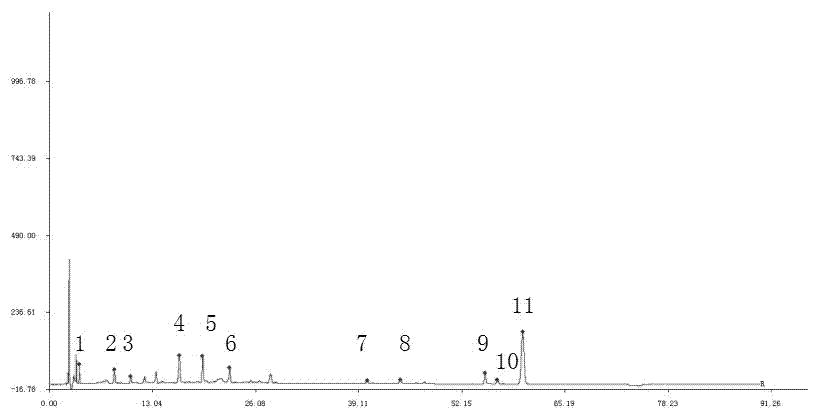

Image

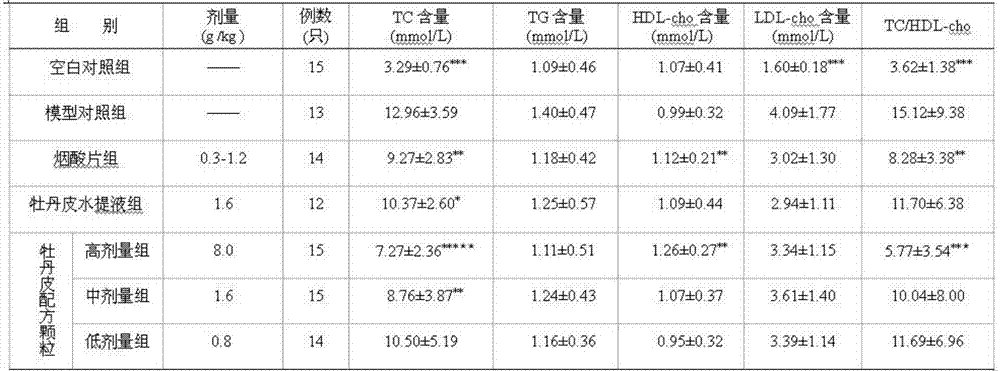

Examples

Embodiment 1

[0031] (1) Take 50kg of decoction pieces of Moutan cortex, add water to decoct twice, add 40kg of water for the first time, infiltrate for 0.5 hours, heat to boiling and decoct for 2 hours, filter the medicinal liquid, add 40kg of water for the second time, heat to boiling After decocting for 1 hour, the medicinal liquid was filtered, and the two filtrates were combined.

[0032] (2) Pump the filtrate into the liquid medicine storage tank, let it stand for 1 hour, and filter it with a 300-mesh filter cloth to obtain the liquid medicine. The liquid medicine is concentrated in a concentrator under reduced pressure until it is concentrated to a liquid extract with a relative density of 1.08 at 60°C. The vapor pressure of the concentrator is 0.08Mpa, the vacuum degree is -0.07Mpa, and the concentration temperature is 70°C.

[0033] (3) Mix the liquid extract with dextrin, stir evenly, and spray dry. The process parameters are: liquid medicine preheating temperature 50°C; air inlet...

Embodiment 2

[0040] (1) Take 40kg of decoction pieces of Moutan Cortex, add water to decoct twice, add 480kg of water for the first time, infiltrate for 1 hour, heat to boiling and decoct for 1.5 hours, filter the medicinal liquid, add 480kg of water for the second time, heat to boiling After decocting for 1.5 hours, the medicinal solution was filtered, and the two filtrates were combined.

[0041] (2) Pump the filtrate into the liquid medicine storage tank, let it stand for 1.5 hours, filter with a 300-mesh filter cloth to obtain the liquid medicine, place the liquid medicine in a concentrator to concentrate under reduced pressure, and concentrate to a fluid extract with a relative density of 1.10 at 60°C. The steam pressure of the concentrator is 0.08Mpa, the vacuum degree is -0.08Mpa, and the concentration temperature is 65°C.

[0042](3) Mix the liquid extract with auxiliary materials such as dextrin, the amount of auxiliary materials added is 12% of the quality of Moutan Cortex decoct...

Embodiment 3

[0049] (1) Take 90kg of decoction pieces of Moutan Cortex, add water to decoct twice, add 900kg of water for the first time, infiltrate for 1 hour, heat to boiling and decoct for 0.5 hour, filter the medicinal liquid, add 900kg of water for the second time, heat to boiling After decocting for 0.5 hour, the medicinal solution was filtered, and the two filtrates were combined.

[0050] (2) Pump the filtrate into the liquid medicine storage tank, let it stand for 2 hours, and filter it with a 300-mesh filter cloth to obtain the liquid medicine. The liquid medicine is concentrated in a concentrator under reduced pressure until it is concentrated to a fluid extract with a relative density of 1.12 at 60°C. The steam pressure of the concentrator is 0.09Mpa, the vacuum degree is -0.09Mpa, and the concentration temperature is 60°C.

[0051] (3) Mix the liquid extract with auxiliary materials such as dextrin, the amount of auxiliary materials added is 1% of the quality of Moutan cortex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com