Method for preparing low-clinker and high-phosphorus-slag cement composite cementitious material

A technology of composite cementitious materials and composite admixtures, applied in the direction of cement production, etc., can solve the problems of polluted land and water bodies, long setting time, low early strength, etc., and achieve high utilization rate, short setting time and high early strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

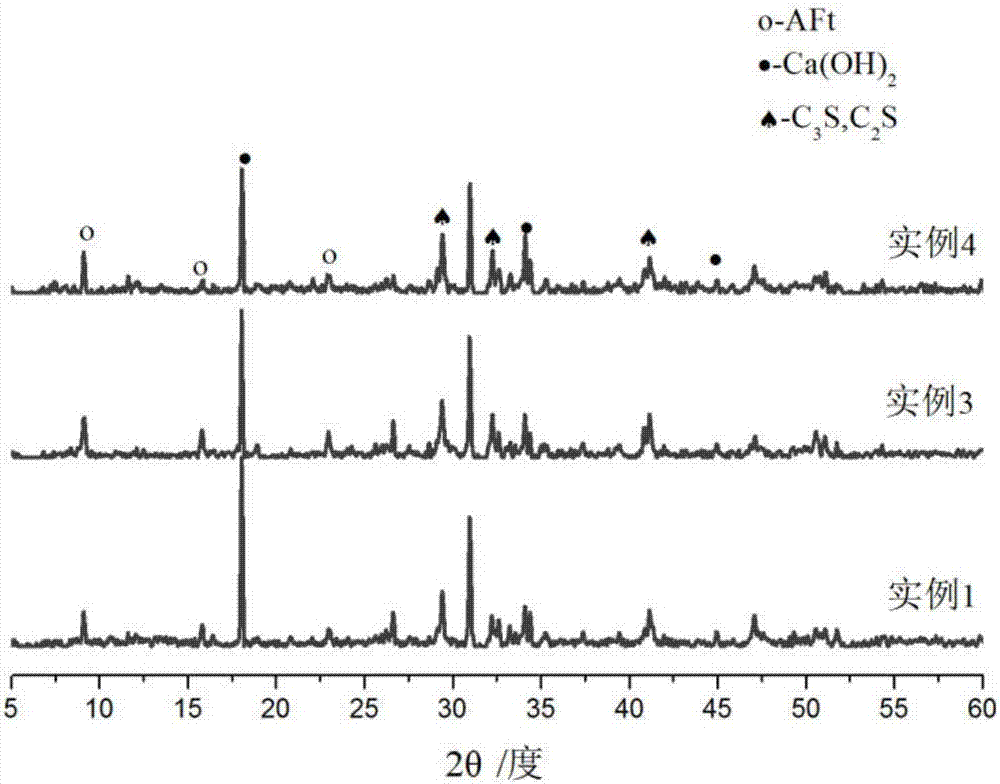

Embodiment 1

[0039] The raw material components of low clinker and high phosphorus slag cement composite cementitious material are: 30% clinker, 40% phosphorus slag, 30% composite admixture, wherein the composite admixture includes 5% steel slag, 10% fly ash, 10% % limestone, 5% gypsum.

[0040] The raw materials are mechanically mixed according to the predetermined proportion, and after mixing evenly, water is added according to the water-cement ratio of 0.5, and stirred in a mortar mixer for 2 minutes, and the cement composite cementitious material with low clinker and high phosphorus slag is obtained after completion.

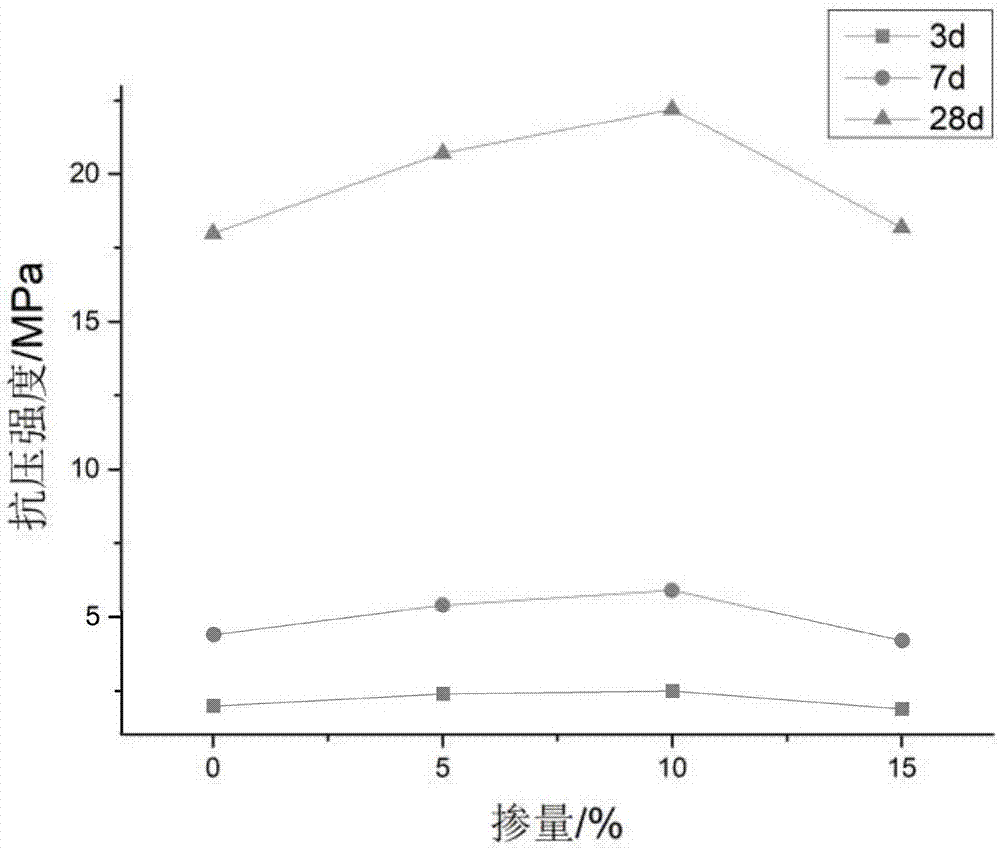

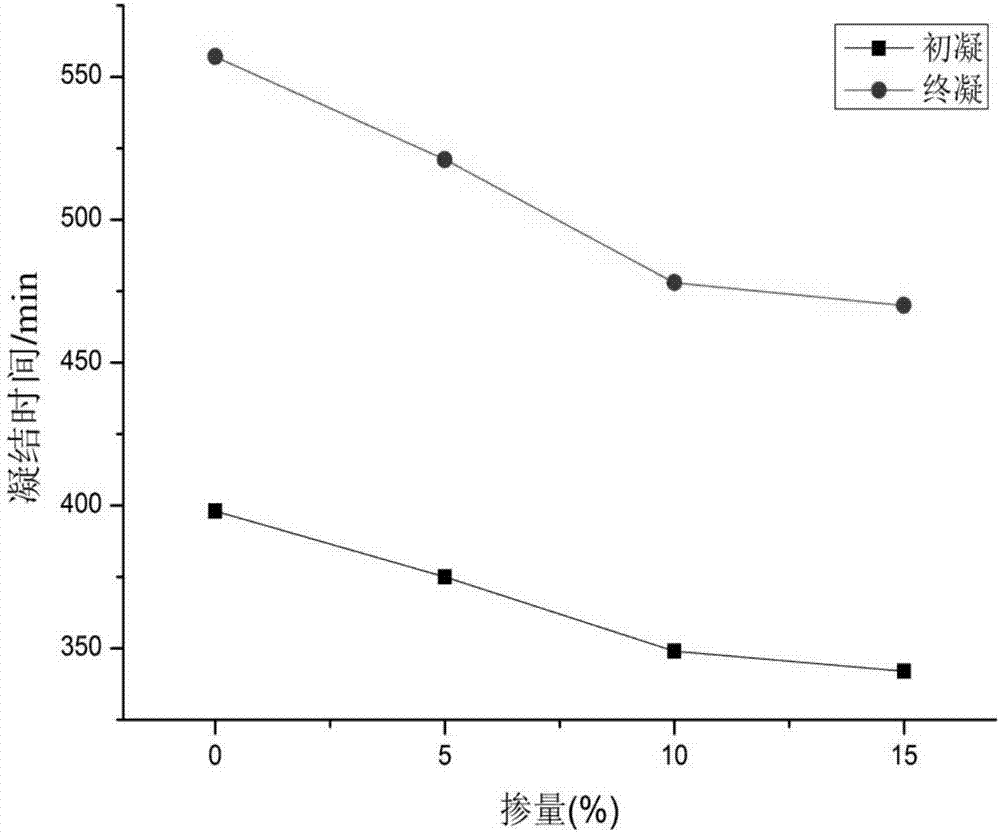

[0041] Test results: The compressive strength of the cement composite cementitious material with low clinker and high phosphorus slag was 2.0MPa, 4.4MPa, and 18.0MPa at 3d, 7d, and 28d, respectively, and the initial setting and final setting times were 398min and 557min, respectively.

Embodiment 2

[0043] The raw material components of low clinker and high phosphorus slag cement composite cementitious material are: 25% clinker, 40% phosphorus slag, 5% metakaolin, 30% composite admixture, wherein the composite admixture includes 5% steel slag, 10% Fly ash, 10% limestone, 5% gypsum.

[0044] The raw materials are mechanically mixed according to the predetermined proportion, and after mixing evenly, water is added according to the water-cement ratio of 0.5, and stirred in a mortar mixer for 2 minutes, and the cement composite cementitious material with low clinker and high phosphorus slag is obtained after completion.

[0045] Test results: the compressive strengths of cement composite cementitious materials with low clinker and high phosphorus slag at 3d, 7d, and 28d are 2.4MPa, 5.4MPa, and 20.9MPa respectively, which are higher than those obtained in Example 1 without metakaolin mixed with samples 3d, 7d, and 28d The compressive strength increased by 16.7%, 18.5%, and 13....

Embodiment 3

[0047] The raw material components of low clinker and high phosphorus slag cement composite cementitious material are: 20% clinker, 40% phosphorus slag, 10% metakaolin, 30% composite admixture, wherein the composite admixture includes 5% steel slag, 10% Fly ash, 10% limestone, 5% gypsum.

[0048] The raw materials are mechanically mixed according to the predetermined proportion, and after mixing evenly, water is added according to the water-cement ratio of 0.5, and stirred in a mortar mixer for 2 minutes, and the cement composite cementitious material with low clinker and high phosphorus slag is obtained after completion.

[0049] Test results: the compressive strength of the cement composite cementitious material with low clinker and high phosphorus slag at 3d, 7d, and 28d is 2.5MPa, 5.9MPa, and 22.2MPa respectively. The compressive strength of metakaolin samples increased by 20.0%, 25.4%, and 18.9% respectively at 3d, 7d, and 28d; Shorten 49min, 79min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com