Heat conduction polymer composite material with isolation double-network structure and preparation method thereof

A heat-conducting polymer and composite material technology, applied in the field of heat-conducting polymer-based composite materials and their preparation, polymer-based composite materials and their preparation, can solve the problems of reducing interface thermal resistance, limited synergistic efficiency, etc. Avoid the deterioration of mechanical properties and processing properties, and have good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the thermally conductive composite material provided by the present invention can be implemented in the following manner, and the process steps of the method are:

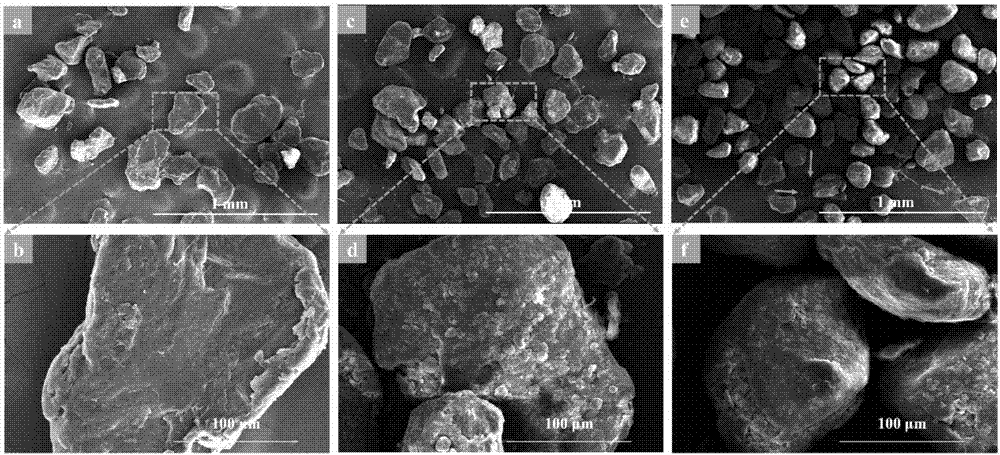

[0048] 1) After fully premixing the dried thermoplastic polymer matrix material with filler A, melt blending is carried out above the melting temperature (or melting point) of the thermoplastic polymer matrix, and then the blended mixture is pulverized and sieved out a certain amount. Particles of micron size are binary composite particles with filler A heat conduction network;

[0049] 2) Put the above-mentioned binary particles and a certain amount of adhesive together and stir at high speed for a certain period of time, so that the surface of the particles is evenly coated with a layer of adhesive; then add filler B and mix with high-speed stirring, so that the filler B adheres to the surface of the binary particles to produce ternary composite particles with two kinds of fillers...

Embodiment 1

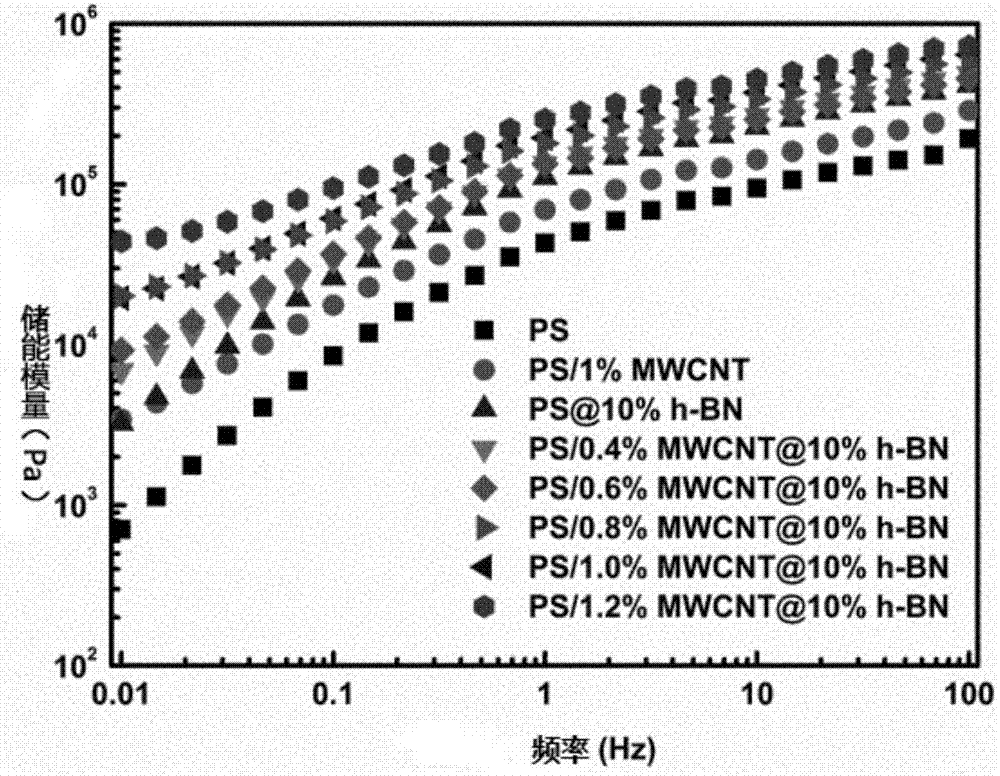

[0054] 100 parts by volume of polystyrene (PS) pellets and 1.12 parts by volume of multi-walled carbon nanotubes with an average length of 1.5 μm and an outer diameter of 9.5 nm are fully premixed, then put into an internal mixer, and Mix at 190° C. and 60 rpm for 20 minutes; then pulverize the polystyrene mixed with carbon nanotubes, and screen out particles with a size of 10-355 μm.

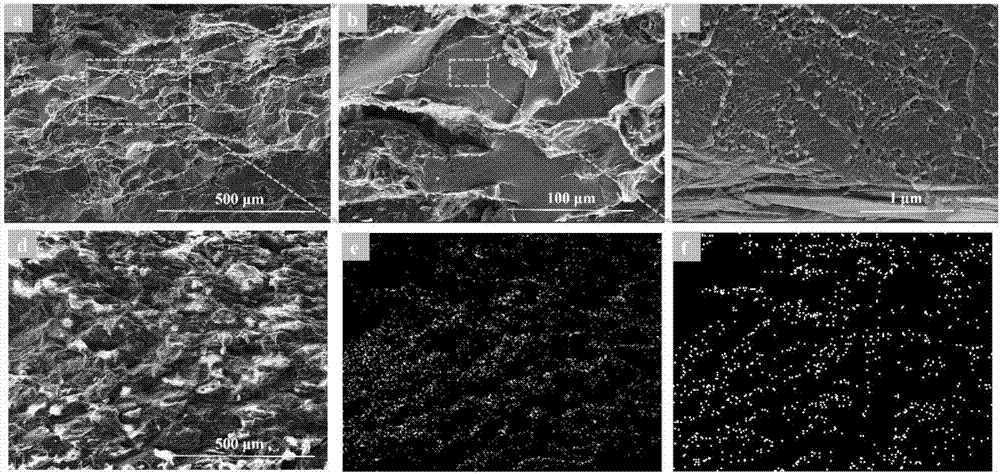

[0055] Premix the screened particles with hexagonal boron nitride with a particle size of 2-3μm at a volume ratio of 90:10, put them in a high-speed mixer and mix them for 2 minutes at a speed of 20,000rad / min, and then dry them The composite particles were pressed into a plate at 190° C. to obtain a thermally conductive composite material with an isolated double network structure. The raw material consumption of each embodiment of the present invention and comparative example is as shown in table 1.

[0056] The obtained thermally conductive composite material was tested for mechanical proper...

Embodiment 2

[0067] Formula: matrix resin (nylon 6), filler A (graphene nanosheets) that acts as a bridge and forms a thermally conductive network alone, thermally conductive filler B (hexagonal boron nitride) that acts as an isolation effect and forms an isolated network structure, adhesive ( VAE707 emulsion).

[0068] Preparation:

[0069] 1) Fully premix nylon 6 (PA-6) pellets with graphene nanosheets with a flake size of 3-5 μm at a volume fraction ratio of 100:5 and put them into an internal mixer at 245°C. Mix at 60rpm for 20min; then grind the nylon 6 mixed with graphene, and screen out the particles with a size of 75-1250μm;

[0070] 2) Put 100 parts by mass of the above particles into a high-speed stirrer, add 16.7 parts by mass of VAE707 latex, mix at a speed of 20000rad / min for 1min, and then mix according to the volume ratio of 100:19.16 (binary Add hexagonal boron nitride with a particle size of 2-3 μm in the proportion of particles: hexagonal boron nitride), and then contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com