Halogen-free environmentally-friendly flame-retardant ABS / PC resin alloy

A kind of epoxy resin, environmental protection technology, applied in the field of halogen-free environmental protection flame retardant ABS/PC resin alloy, can solve the problems of environmental and human harm, unfriendly environment, low smoke emission, etc., to achieve good flame retardant effect and environmental friendliness , The effect of improving oil performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

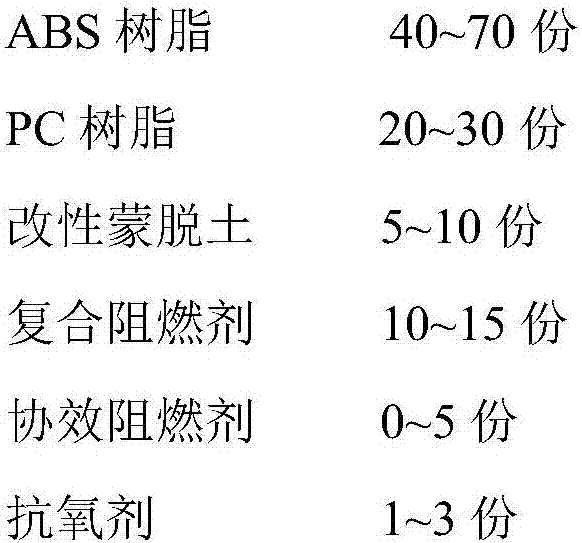

[0027] The halogen-free environmentally friendly flame-retardant ABS / PC resin alloy is characterized in that it consists of the following substances by mass:

[0028]

[0029] The preparation process of the modified montmorillonite is as follows: in parts by mass, 6 parts of montmorillonite are added to 100 to 150 parts of water, stirred rapidly and heated to 80 to 90°C, and then 0.7 parts of octadecyltri Methyl ammonium chloride, stirred at constant temperature for 12-24 hours, filtered, separated, washed until no white precipitate was detected by silver nitrate, then dried under vacuum at 80-90°C for 20-24 hours, and then mixed with 50 parts of ground and pulverized montmorillonite Mix the epoxy resin at 70-75°C for 3-4 hours, then add 170 parts of bisphenol A bis(diphenyl phosphate) and 60 parts of zinc borate to prepare modified montmorillonite;

[0030] The preparation process of the composite flame retardant is as follows: in parts by mass, 1 part of silane coupling a...

Embodiment 2

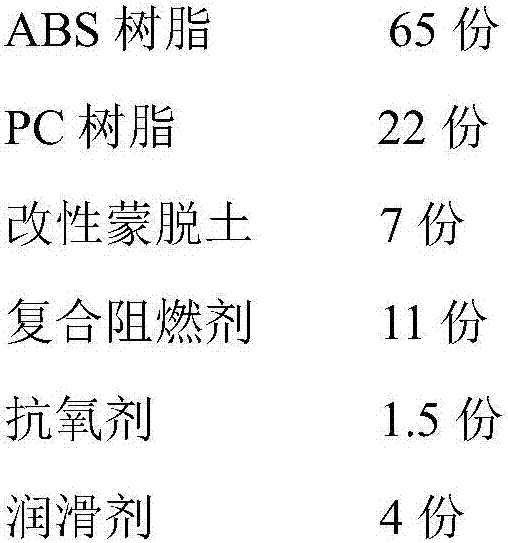

[0032] The halogen-free environmentally friendly flame-retardant ABS / PC resin alloy is characterized in that it consists of the following substances by mass:

[0033]

[0034]

[0035] The preparation process of the modified montmorillonite is as follows: in parts by mass, 10 parts of montmorillonite is added to 100-150 parts of water, stirred rapidly and heated to 80-90°C, and then 1 part of octadecyltri Methyl ammonium chloride, stirred at constant temperature for 12-24 hours, filtered, separated, washed until no white precipitate was detected by silver nitrate, then dried under vacuum at 80-90°C for 20-24 hours, and then the ground and pulverized montmorillonite was mixed with 120 parts Mix the epoxy resin at 70-75°C for 3-4 hours, then add 90 parts of bisphenol A bis(diphenyl phosphate) and 40 parts of zinc borate to prepare modified montmorillonite;

[0036] The preparation process of the composite flame retardant is: according to parts by mass, spray 3 parts of sil...

Embodiment 3

[0038] Halogen-free environmentally friendly flame-retardant ABS / PC resin alloy consists of the following substances by mass:

[0039]

[0040]The preparation process of the modified montmorillonite is as follows: in parts by mass, 10 parts of montmorillonite is added to 100-150 parts of water, stirred rapidly and heated to 80-90°C, and then 1 part of octadecyltri Methyl ammonium chloride, stirred at constant temperature for 12-24 hours, filtered, separated, washed until no white precipitate was detected by silver nitrate, then dried under vacuum at 80-90°C for 20-24 hours, and then mixed with 50 parts of ground and pulverized montmorillonite Mix the epoxy resin at 70-75°C for 3-4 hours, then add 180 parts of bisphenol A bis(diphenyl phosphate) and 40 parts of zinc borate to prepare modified montmorillonite;

[0041] The preparation process of the composite flame retardant is: according to parts by mass, spray 3 parts of silane coupling agent KH550 into 30 parts of ammonium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com