Preparation method of separation-purification film for deicing waste liquid of airplane

A technology for waste liquid separation and crystal seeding, which is applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of high separation energy consumption, and achieve the effect of simple treatment process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

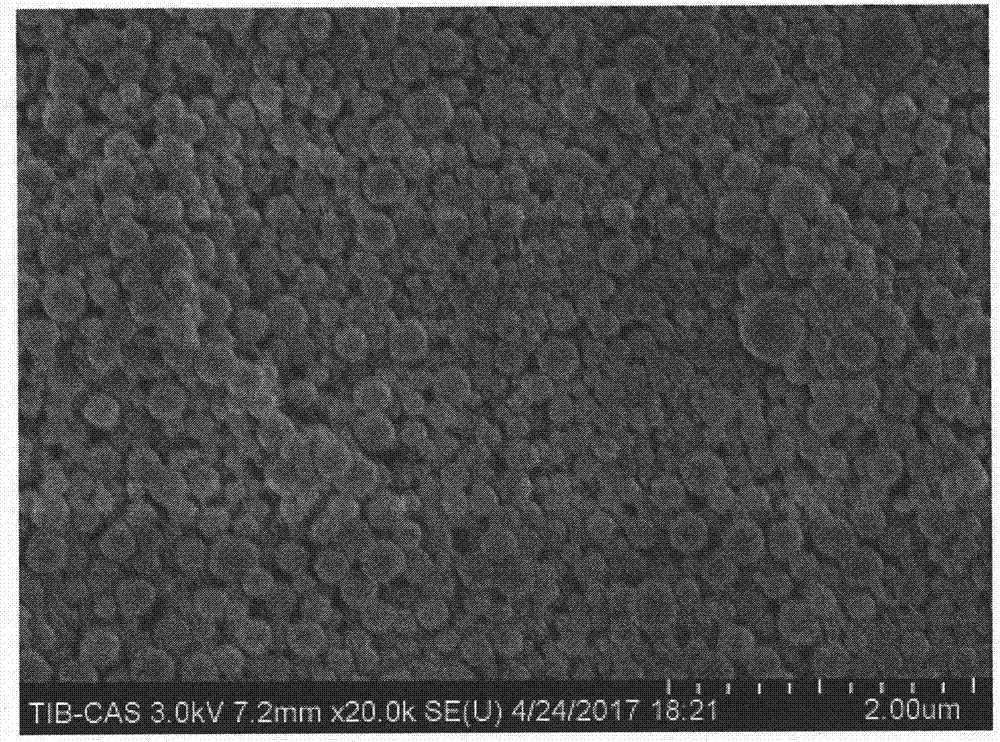

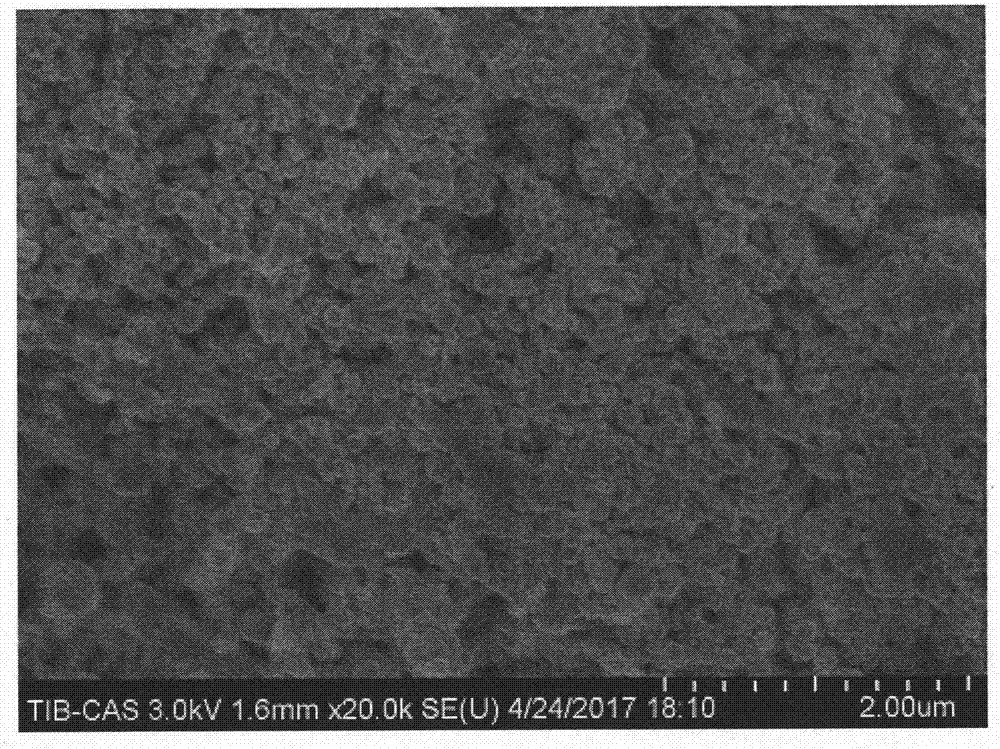

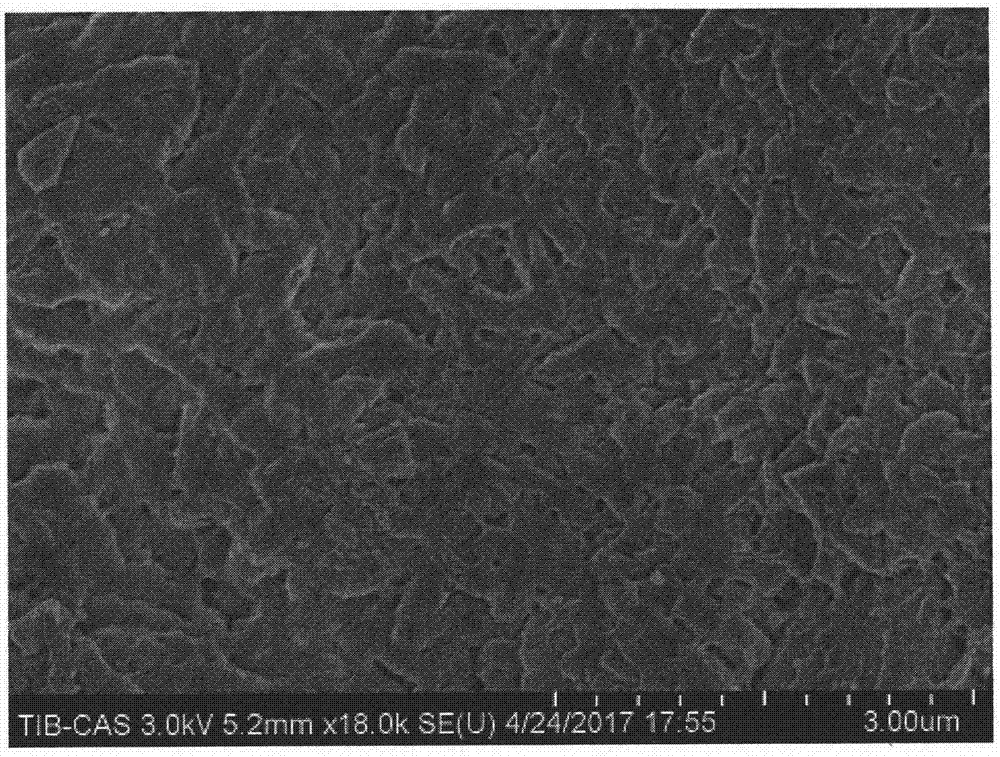

Image

Examples

Embodiment 1

[0025] (1) Use 1200# sandpaper to smooth the surface of the ceramic tube. After polishing is completed, wash with deionized water, 1mol / L hydrochloric acid, 1mol / L sodium hydroxide solution, and wash with the distilled water pH=7 after washing as the standard. After washing, it was dried in an oven at 50°C for 24 hours. After drying, a line was drawn at 1 cm from both ends of the support, leaving a 2 cm long alumina tube in the middle to be coated with crystals.

[0026] (2) Take 4.736ml of deionized water and add it to 1.021g of aluminum isopropoxide, place it on an electromagnetic stirrer and stir until the solution is uniform, add 0.040g of NaOH, continue to stir for 5-10 minutes until the mixture is uniform, and add 13.089g of tetramethylhydrogen dropwise Bring ammonium oxide to solution, stir well and add 1.280ml 30% silica sol dropwise. After pre-crystallization for 2.5 hours, it was transferred to the reactor and placed in an oven at 80°C for crystallization for 8 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com