Method for preparing semiconductor BiOxCly type photocatalyst by utilizing industrial wastewater

A technology of industrial wastewater and photocatalyst, which is applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problem of unstable effluent quality, long time-consuming period, and difficult sludge treatment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

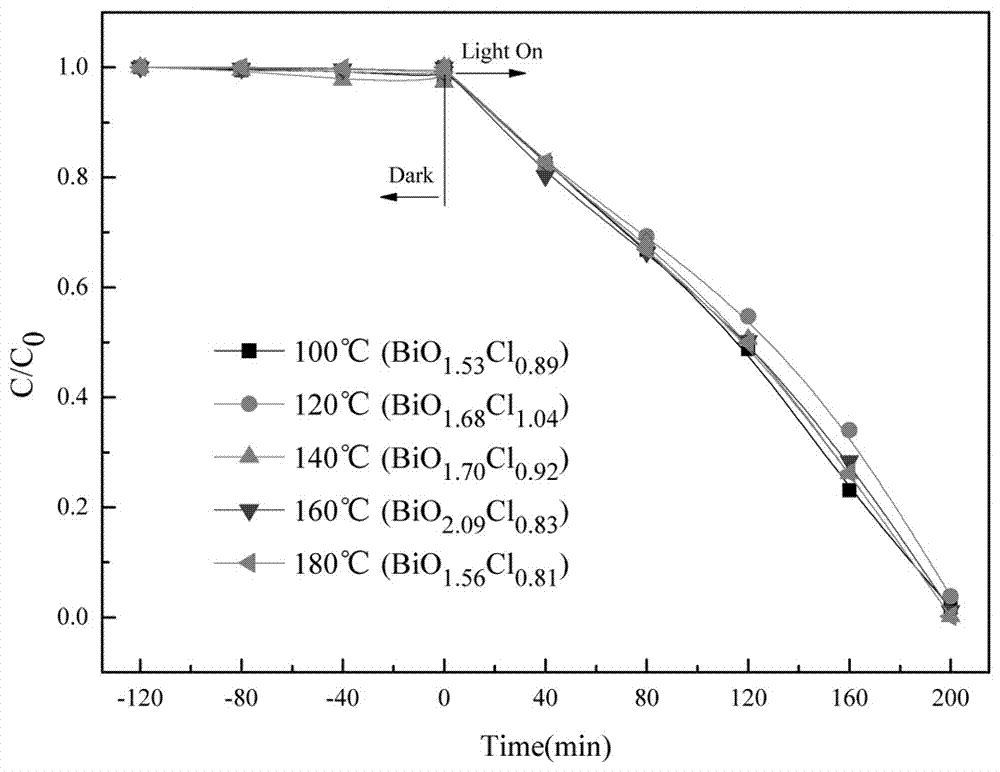

Embodiment 1

[0027] Add 5 parts of 0.97g of bismuth nitrate pentahydrate to 5 parts of 80mL glyphosate industrial wastewater mother liquor from the glyphosate project production line of Xingfa Group, and ultrasonically And stir for 30 minutes, so that bismuth nitrate pentahydrate is evenly dispersed in the industrial wastewater solution; then all the obtained mixed solution of industrial wastewater and bismuth nitrate pentahydrate is transferred to a 100mL reactor, and the reactor is tightened; the reactor is placed in JXF12- In a 100-type homogeneous reactor, the BiO 1.53 Cl 0.89 、BiO 1.68 Cl 1.04 、BiO 1.70 Cl 0.92 、BiO 2.09 Cl 0.83 、BiO 1.56 Cl 0.81 A total of 5 kinds of photocatalysts; then the cooled reactor was taken out, the mixed solution was taken out and washed with deionized water for 3 times, and then suction filtered, and the prepared BiO x Cl y type semiconductor photocatalyst. Put the prepared semiconductor photocatalyst into an electric drying oven and dry for 2h ...

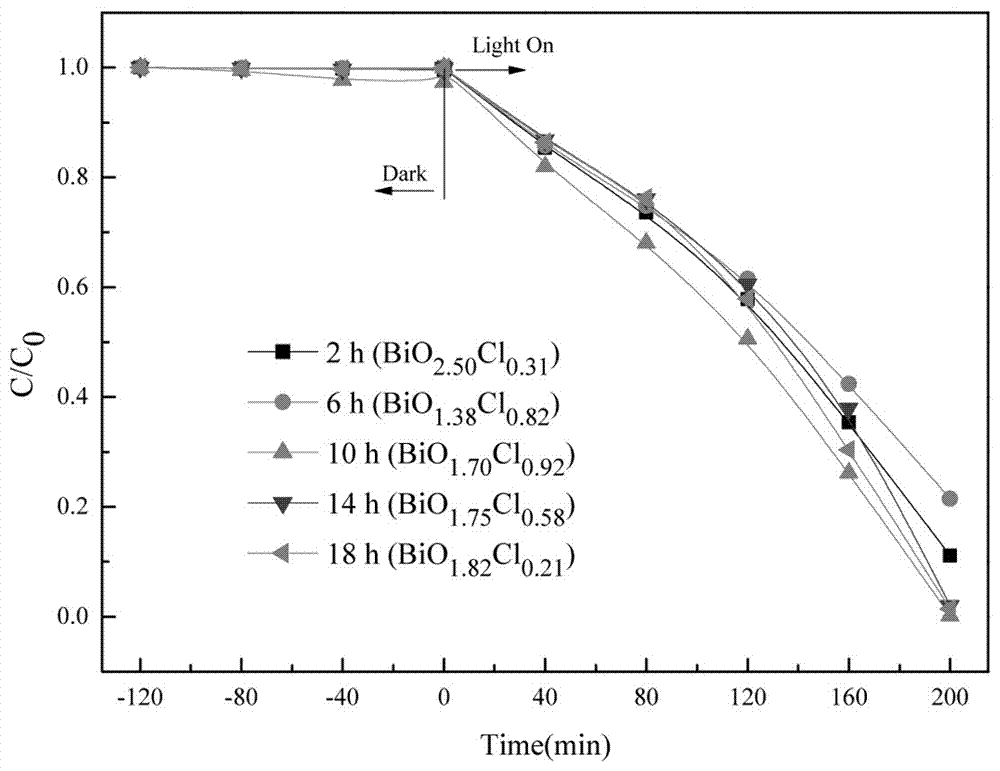

Embodiment 2

[0030] Add 5 parts of 0.97g of bismuth nitrate pentahydrate to 5 parts of 80mL glyphosate industrial wastewater mother liquor from the glyphosate project production line of Xingfa Group, and ultrasonically And stir for 30 minutes, so that bismuth nitrate pentahydrate is evenly dispersed in the industrial wastewater solution; then all the obtained mixed solution of industrial wastewater and bismuth nitrate pentahydrate is transferred to a 100mL reactor, and the reactor is tightened; the reactor is placed in JXF12- In a 100-type homogeneous reactor, the BiO 2.50 Cl 0.31 、BiO 1.38 Cl 0.82 、BiO 1.70 Cl 0.92 、BiO 1.75 Cl 0.58 、BiO 1.82 Cl 0.21 A total of 5 photocatalysts; then the cooled reactor was taken out, the mixed solution was taken out and washed with deionized water for 3 times and then suction filtered, and the prepared semiconductor BiO x Cl y type photocatalyst. Put the prepared photocatalyst into an electric drying oven and dry it for 2h to obtain the desired...

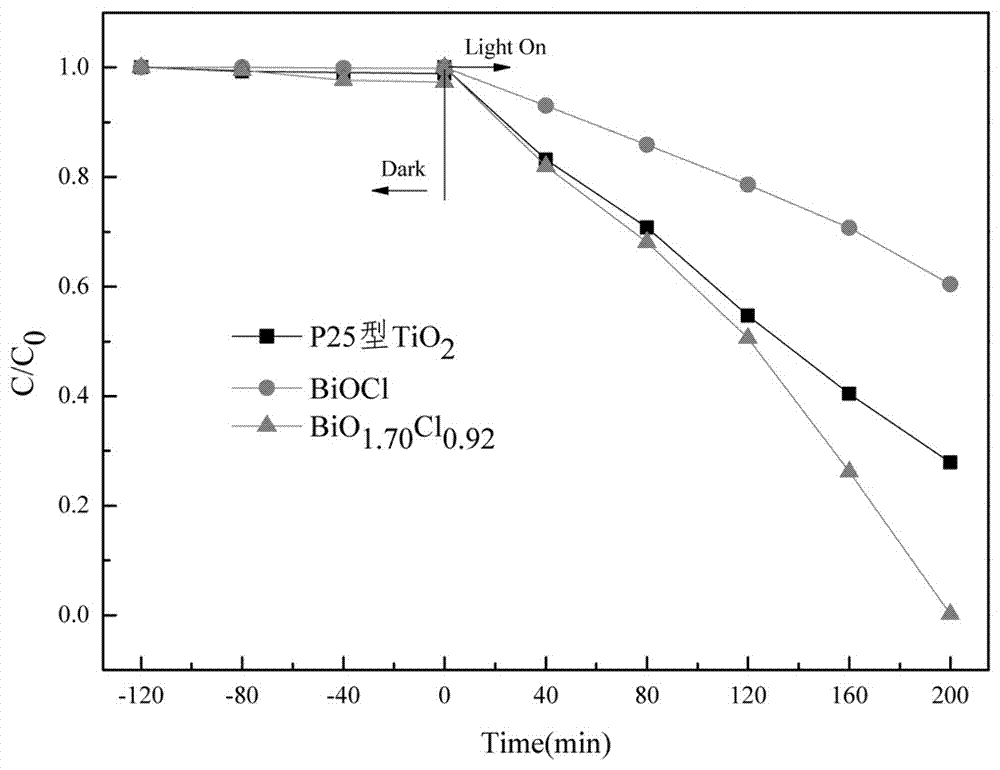

Embodiment 3

[0033] Add 2 parts of 0.97g of bismuth nitrate pentahydrate to 80mL of glyphosate industrial wastewater mother liquor and 1.4625g / L sodium chloride solution from the glyphosate project production line of Xingfa Group, respectively. Ultrasonic and stir in a high-frequency numerically controlled ultrasonic machine for 30 minutes, so that bismuth nitrate pentahydrate is evenly dispersed in the solution; then all the mixed solution obtained is transferred to a 100mL reactor, and the reactor is tightened; the reactor is placed in a JXF12-100 In a homogeneous reactor, reacted at 140 °C for 10 h and then cooled to room temperature naturally to obtain BiO 1.70 Cl 0.92 Semiconductor photocatalyst and bismuth oxychloride semiconductor photocatalyst; Then take out the reactor after cooling, take out the solution wherein and wash with deionized water 3 times and then suction filter, on the filter paper are prepared 2 kinds of semiconductor photocatalysts. Put the prepared two kinds of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com