Preparation method of porous activated carbon for air purification

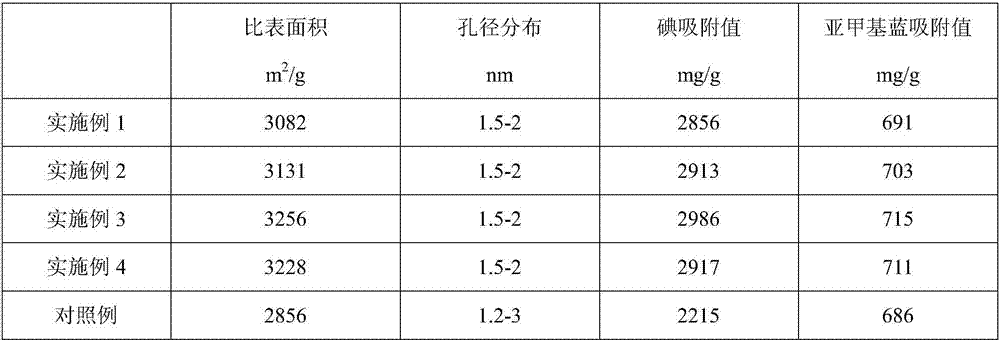

A porous activated carbon and air purification technology, applied in the field of activated carbon, can solve the problems of limited purification adsorption performance, uneven pore size distribution, and low purification efficiency of activated carbon, and achieve the effect of improving adsorption performance, uniform pore size distribution, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of porous activated carbon for air purification, comprising the following steps:

[0020] Step 1, drying and pulverizing the coconut shell, the particle size after pulverization is 800-1000 microns to obtain coconut shell particles;

[0021] Step 2, get 30 parts of coconut shell particles in parts by weight and 1 part of maleic anhydride, 0.5 part of maleic anhydride, 1 part of toluene diisocyanate, 5 parts of diethylene glycol and 100 parts of solvent mix, then as In a tube furnace, heat up and carbonize under the protection of an inert gas. After carbonization, wash with deionized water until neutral, filter and dry at 100°C. Grind to a particle size of 1-3mm to obtain primary particles. The solvent is a mixture of ethanol and isopropanol, the volume ratio of ethanol to isopropanol is 5:1, the heating rate of carbonization is 10°C / min, and the carbonization temperature is 800°C;

[0022] Step 3: Mix 10 parts of primary granules with 1 part of sod...

Embodiment 2

[0024] A preparation method of porous activated carbon for air purification, comprising the following steps:

[0025] Step 1, drying and pulverizing the coconut shell, the particle size after pulverization is 800-1000 microns to obtain coconut shell particles;

[0026] Step 2, get 35 parts of coconut shell particles in parts by weight and 2 parts of maleic anhydride, 0.6 part of maleic anhydride, 2 parts of toluene diisocyanate, 6 parts of diethylene glycol and 120 parts of solvent mix, then as for In a tube furnace, heat up carbonization under the protection of an inert gas. After carbonization, wash with deionized water until neutral, filter and dry at a temperature of 105°C. Grind to a particle size of 1-3mm to obtain primary particles. The solvent is a mixture of ethanol and isopropanol, the volume ratio of ethanol and isopropanol is 5:1, the heating rate of carbonization is 11°C / min, and the carbonization temperature is 900°C;

[0027] Step 3: Mix 10 parts of primary gra...

Embodiment 3

[0029] A preparation method of porous activated carbon for air purification, comprising the following steps:

[0030] Step 1, drying and pulverizing the coconut shell, the particle size after pulverization is 800-1000 microns to obtain coconut shell particles;

[0031] Step 2, get 36 parts of coconut shell particles in parts by weight and 3 parts of maleic anhydride, 0.8 part of maleic anhydride, 2 parts of toluene diisocyanate, 7 parts of diethylene glycol and 140 parts of solvent mix, then as for In a tube furnace, heat up carbonization under the protection of an inert gas. After carbonization, wash with deionized water until neutral, filter and dry at a temperature of 110°C. Grind to a particle size of 1-3mm to obtain primary particles. The solvent is a mixture of ethanol and isopropanol, the volume ratio of ethanol to isopropanol is 5:1, the heating rate of carbonization is 12°C / min, and the carbonization temperature is 900°C;

[0032] Step 3: Mix 10 parts of primary gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com