Fully-synthetic cutting liquid and preparation method thereof

A cutting fluid, fully synthetic technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of high cost of cutting fluid, affecting water quality and soil environment, corruption and deterioration, etc., to reduce the occurrence of occupational diseases, improve the working environment, and reduce smoke The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

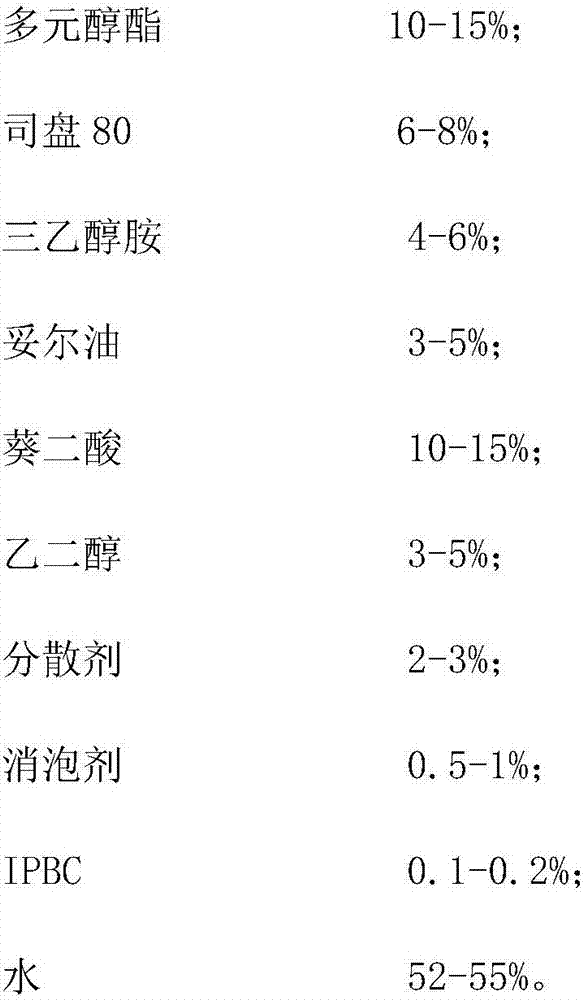

[0022] The formula composition of fully synthetic cutting fluid of the present invention is by weight:

[0023]

[0024]

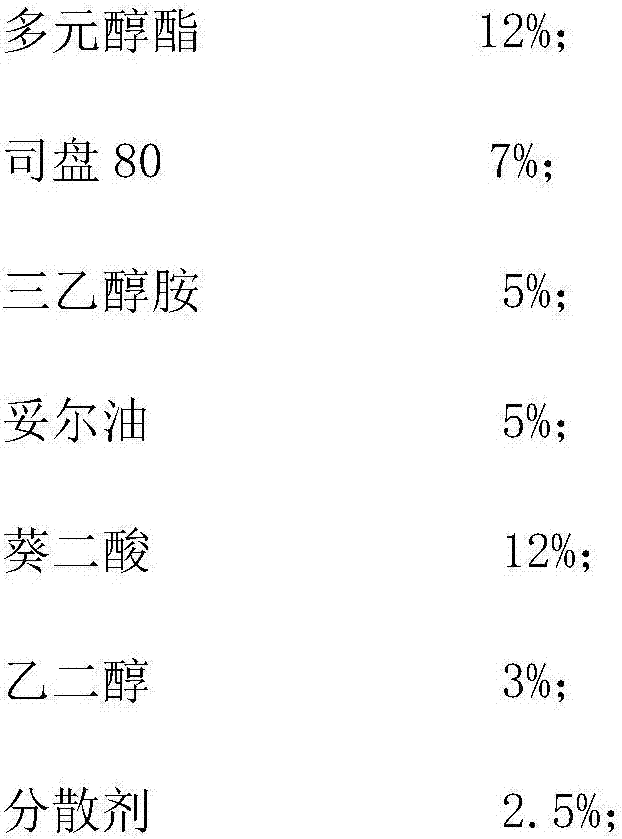

[0025] As a preferred embodiment, the formula components of the fully synthetic cutting fluid in this embodiment are by weight:

[0026]

[0027] The polyol esters are generally soluble in water, and most polyols are viscous liquids or crystalline solids with high boiling point, strong dissolving ability for polar substances, and low toxicity and volatility. Its boiling point, viscosity, relative density and melting point increase with the increase of molecular weight, and it has strong crystallinity and high bonding strength.

[0028] Span 80 (Span 80) is a yellow oily liquid, dispersible in warm water and ethanol, soluble in organic solvents such as propylene glycol, liquid paraffin, ethanol, methanol or ethyl acetate, HLB=4.3, often used as wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com