Aluminum oxide nano-needles and preparation method and application of aluminum oxide nano-needle and hole composite array structure

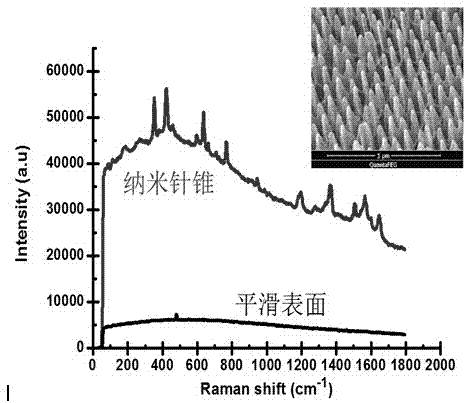

A technology of alumina nano-composite arrays, applied in the field of material science, can solve the problems of limited and unreachable surface enhancement performance, and achieve the effects of low cost, high strength and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

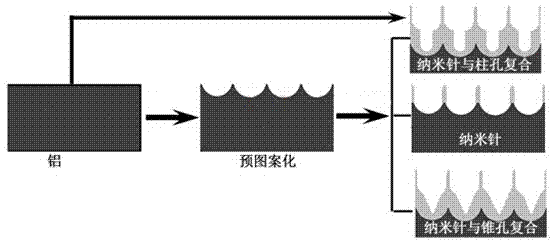

Method used

Image

Examples

Embodiment 1

[0023] As one of the more preferred embodiments, the method may include: using a low-temperature (5-18°C) oxalic acid solution as the electrolyte, with an oxalic acid concentration of 0.1-1M, and performing a mild (current density 2 ) Oxidation for 3h, and then use a mixed solution of 6wt% phosphoric acid solution and 1.8wt% chromic acid solution to soak and peel off the oxide layer to obtain hexagonal ordered pits to manufacture the pre-patterned aluminum surface, and the period of the pits is 80~ 110nm, the period of the pit determines the period of the final hole; then the initiation point formed by using the pit as a hole is subjected to mild oxidation for 25~250s under the same conditions as above to obtain a columnar hole structure with a height of 50~500nm, and finally the The obtained alumina column holes are immersed in a phosphoric acid solution with a temperature of 20-70°C and a concentration of 0.1-4M and corroded for 10-100 minutes, so that the pore walls are just ...

Embodiment 2

[0032] 1) Remove the organic grease and inorganic impurities on the surface of the aluminum foil by cleaning or grinding, or use the aluminum foil without any treatment;

[0033] 2) Use aluminum foil as anode, platinum electrode as cathode, sulfuric acid and oxalic acid mixed solution as electrolyte, sulfuric acid concentration is 0.012M, oxalic acid concentration is 0.3M, firstly oxidize at 35V for 8min (current density2 ), and then increase the voltage to 110V at a rate of 0.5V / s for high-intensity (current density>30mA / cm 2 ) oxidation, the entire oxidation time is 1.5h, and the temperature is -2°C; after the completion, the sample is immersed in a mixed solution of 1.8wt% chromic acid and 6wt% phosphoric acid at a temperature of 65°C for 3h, so that the alumina is completely denuded Drop the pit structure with a pitch of 200 nm;

[0034] 3) Take the pit as the initiation point of the hole formation, use the phosphoric acid solution with a concentration of 0.23M as the elec...

Embodiment 3

[0037] 1) Remove organic grease and inorganic impurities on the surface of aluminum foil by cleaning or grinding;

[0038] 2) Use aluminum as the anode, graphite electrode as the cathode, and 0.3 M sulfuric acid solution as the electrolyte, at 25V, 10°C for 6h (current density 2 ); After the completion, the sample is immersed in a mixed solution of 1.8wt% chromic acid and 6wt% phosphoric acid at a temperature of 3h for 3h, so that the aluminum oxide is completely eroded away and the pit structure with a spacing of 60 nm is left;

[0039] 3) Use the pit as the initiation point of hole formation, use phosphoric acid solution with a concentration of 0.23M as the electrolyte, and perform high-intensity oxidation at 25V for 1800s at a temperature of 40°C, so that the corrosion of the top hole and the formation of branch holes proceed simultaneously , to obtain a composite array structure of nanoneedles and pillar holes with a height of nano needle cones of 100nm and a height of pill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com