Rare earth element adsorption separation material

A technology for adsorbing and separating materials and elements, which is applied in the direction of solid adsorbent liquid separation, separation method, filtration and separation, etc. It can solve the problems of lack of price stability and exceeding demand expectations, and achieve the effect of improving treatment efficiency and large adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135]

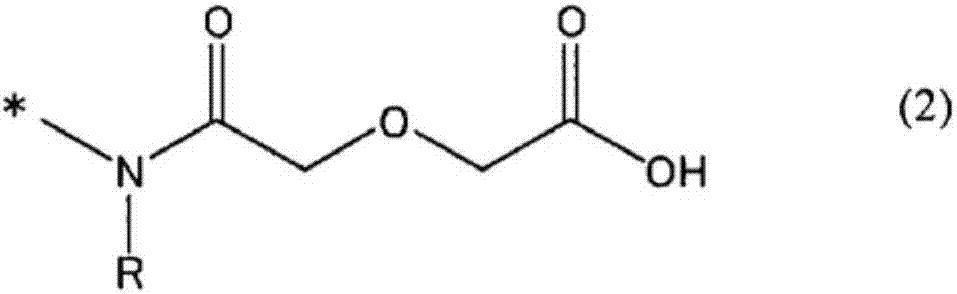

[0136] 16.5 g (0.1 mol) of 2-aminoethyl methacrylate hydrochloride was dissolved in 120 ml of THF, and 15.2 g (0.15 mol) of TEA was poured thereto under cooling with ice. 80 ml of a THF solution containing 11.6 g (0.1 mol) of diglycolic anhydride was added dropwise thereto while maintaining the temperature below 10° C., then the mixture was returned to room temperature, and stirring was continued overnight (about 12 hours).

[0137] The reaction solution was filtered, the filtrate was passed through a silica gel column as it was, washed with THF as an eluent, and the eluted fraction was concentrated. Toluene was added to the obtained concentrate to crystallize, and the precipitated crystals were collected by filtration. The obtained crystals were washed with toluene and dried to obtain DGAA-methacrylate.

[0138]

[0139] Vinylon nonwoven fabric was used as a polymer substrate, and a 50 wt% aqueous solution of DGAA-methacrylate obtained above was used as a monome...

Embodiment 2

[0143]

[0144] Polyethylene nonwoven fabric was used as the polymer substrate, and glycidyl methacrylate (GMA) was used as the monomer solution. To remove dissolved oxygen in the monomer solution, the solution was bubbled with nitrogen for 1 hour.

[0145] The polymer substrate is irradiated with a 90kGy electron beam, and the irradiated polymer substrate is quickly immersed in the monomer solution. The polymer substrate was reacted with the monomer solution at 70° C. for 4 minutes, thereby bonding the grafted chains to the polymer substrate. Then, after thoroughly washing with pure water, the polymer substrate was dried at 40° C. for 1 hour or more, thereby obtaining a GMA-bonded substrate. The graft ratio by weight was 97% by weight.

[0146] Then, the GMA-bonded substrate was dipped in ethylenediamine and allowed to react at 60° C. for 6 hours. The resulting reactant was thoroughly washed sequentially with ethanol and pure water, and dried at 60° C. under reduced pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com