Making method of preconditioned shelled Penaeus vannamei Boone

A production method and preconditioning technology, applied in food ingredients as antimicrobial preservation, food science, food preservation, etc., to achieve good quality, inhibit activity, and increase the effect of shrimp taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

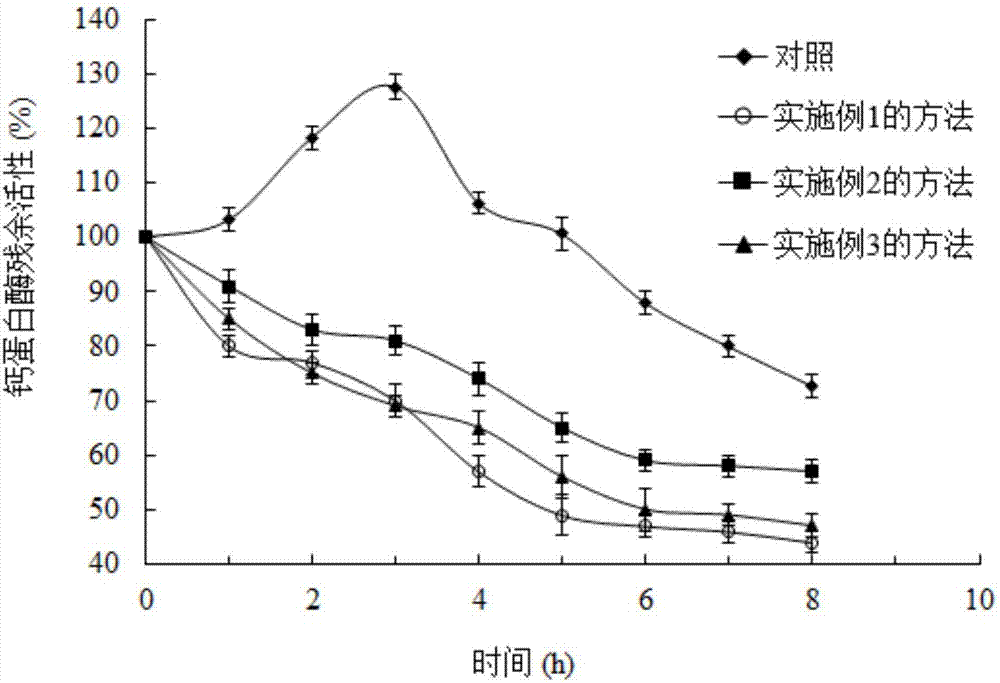

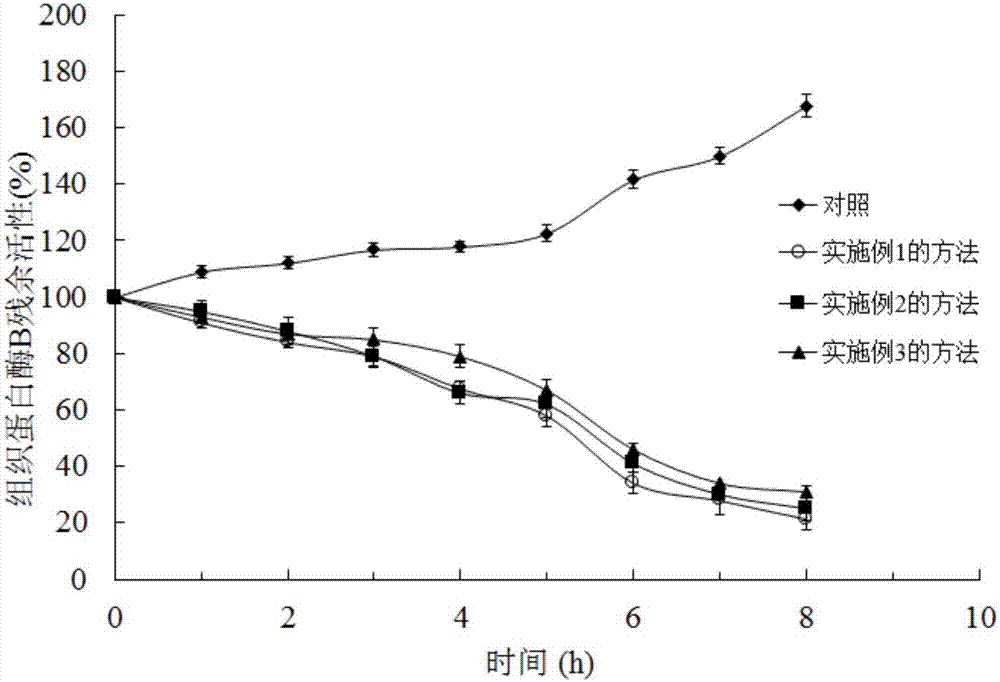

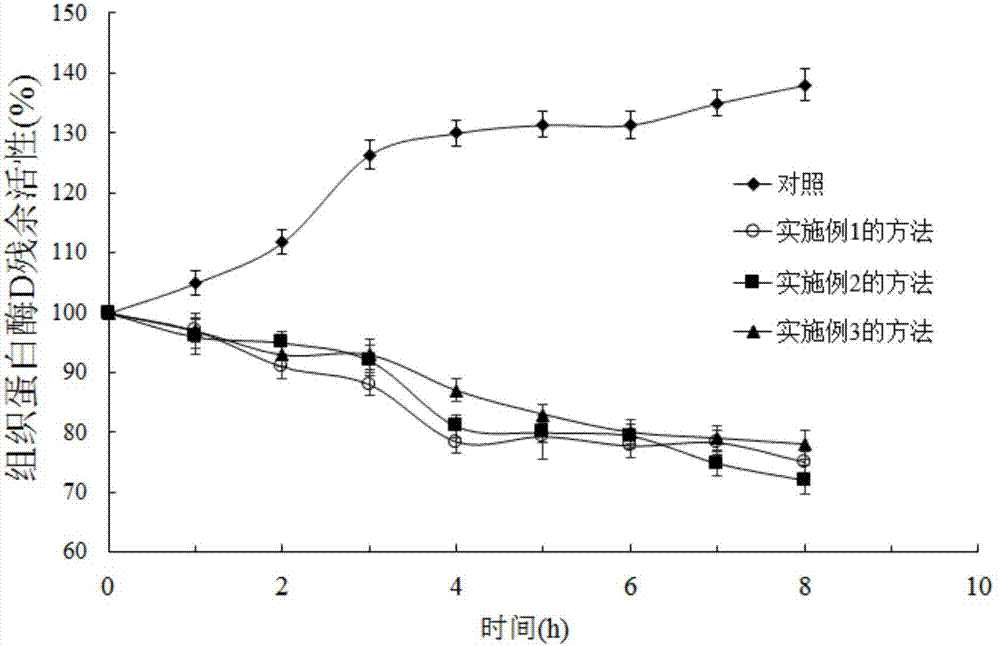

Examples

Embodiment 1

[0037] Clean raw materials of Penaeus vannamei: if using fresh vannamei shrimp, remove the head, shell, and shrimp line, wash and drain in tap water; if using frozen shrimp, thaw at room temperature not exceeding 20°C.

[0038] Preparation of pre-conditioning pickling solution: based on the mass of shrimp raw materials, 6g citric acid, 550g salt, 120g whey protein, 140g egg white, 18g propylene glycol, 2000ml rice wine, stir to dissolve. Add 10kg fresh shrimps and mix well.

[0039] Vacuum tumbling pickling: put the obtained shrimp and pickling liquid mixture into a vacuum tumbling machine (Zhucheng Huagang Machinery Co., Ltd.) for tumbling. The conditions for vacuum tumbling are: (1) vacuuming, vacuum degree 0.05MPa, tumbling speed 8r / min, temperature 10°C, tumbling time 5min, intermittent time 8min, tumbling-intermittent repeat 3 times; (2) discharge Vacuum, under non-vacuum conditions, tumbling speed 10r / min, temperature 10°C, tumbling time 6min, intermittent time 10min, t...

Embodiment 2

[0043] Clean raw materials of Penaeus vannamei: if using fresh vannamei shrimp, remove the head, shell, and shrimp line, wash and drain in tap water; if using frozen shrimp, thaw at room temperature not exceeding 20°C.

[0044]Preparation of pre-conditioning pickling solution: based on the mass of shrimp raw materials, 5g citric acid, 500g salt, 100g whey protein, 150g egg white, 15g propylene glycol, 2200ml rice wine, stir to dissolve. Add 10kg fresh shrimps and mix well.

[0045] Vacuum tumbling pickling: put the obtained shrimp and pickling liquid mixture into a vacuum tumbling machine (Zhucheng Huagang Machinery Co., Ltd.) for tumbling. The conditions for vacuum tumbling are: (1) vacuuming, vacuum degree 0.08MPa, tumbling speed 8r / min, temperature 10°C, tumbling time 5min, intermittent time 8min, tumbling-intermittent repeat 4 times; (2) discharge Vacuum, under non-vacuum conditions, the tumbling speed is 8r / min, the temperature is 15°C, the tumbling time is 5min, and the...

Embodiment 3

[0049] Clean raw materials of Penaeus vannamei: if using fresh vannamei shrimp, remove the head, shell, and shrimp line, wash and drain in tap water; if using frozen shrimp, thaw at room temperature not exceeding 20°C.

[0050] Preparation of pre-conditioning pickling solution: based on the mass of shrimp raw materials, 8g citric acid, 600g salt, 150g whey protein, 100g egg white, 20g propylene glycol, 2000ml rice wine, stir to dissolve. Add 10kg fresh shrimps and mix well.

[0051] Vacuum tumbling pickling: put the obtained shrimp and pickling liquid mixture into a vacuum tumbling machine (Zhucheng Huagang Machinery Co., Ltd.) for tumbling. The conditions for vacuum tumbling are: (1) vacuuming, vacuum degree 0.04MPa, tumbling speed 10r / min, temperature 15°C, tumbling time 6min, intermittent time 10min, tumbling-intermittent repeat 4 times; (2) discharge Vacuum, under non-vacuum conditions, the tumbling speed is 10r / min, the temperature is 12°C, the tumbling time is 6min, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com