Ordered alumina mesoporous material and preparation method thereof

A technology of mesoporous materials and sequenced alumina, which is applied in the field of mesoporous materials, can solve the problems of lowering, collapse of ordered mesoporous structures, specific surface area and pore volume, achieve high catalytic activity, and the preparation method is simple and easy repeat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Under vigorous stirring at 30°C, add 3.5g of EO to 20mL of absolute ethanol solution containing 0.6g of citric acid and 2.0g of 12M hydrochloric acid 106 PO 70 EO 106 and 4.08g of aluminum isopropoxide were completely dissolved to obtain a clear solution; the resulting clear solution was poured into a sealed autoclave for solvothermal pretreatment at 100°C for 24 hours; subsequently, the obtained sol was volatilized in an open state at 60°C Treatment for 24 hours; finally, the obtained solid sample was calcined at 550°C for 5 hours to remove the organic template existing in the mesoporous channels to obtain an alumina mesoporous material sample with a highly ordered two-dimensional hexagonal mesoporous structure.

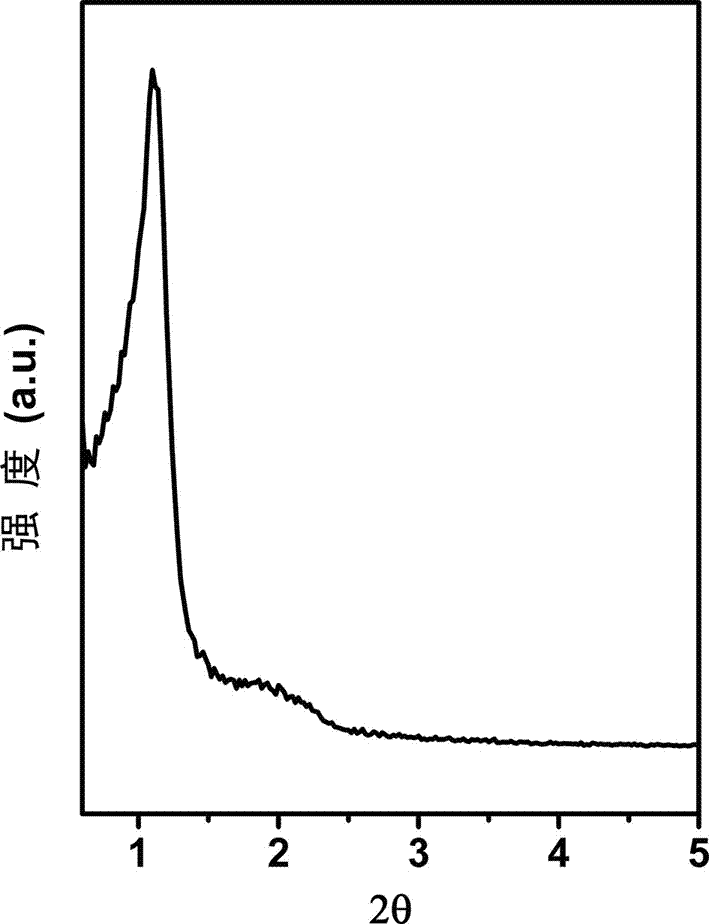

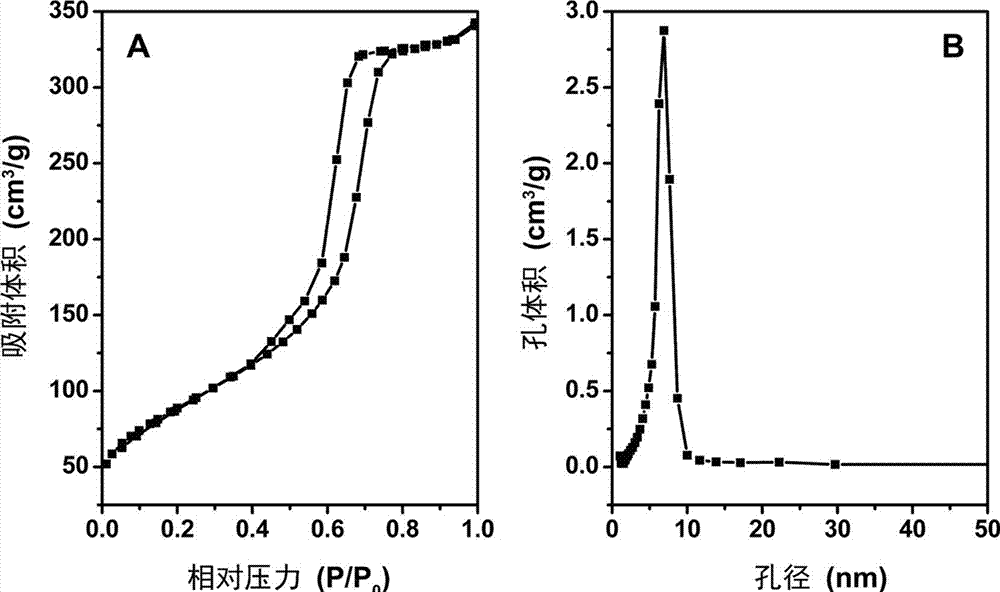

[0029] figure 1 The XRD spectrum of the sample prepared above is given. It can be seen from the figure that the obtained material shows a strong diffraction peak and a relatively weak diffraction peak at 0.90° and 1.56°, respectively. By calculating the r...

Embodiment 2

[0035] Under vigorous stirring at 40°C, add 4.0 g of EO to 20 mL of absolute ethanol solution containing 0.8 g of oxalic acid and 2.6 g of 2M nitric acid 106 PO 70 EO 106 and 7.1g of aluminum nitrate were completely dissolved to obtain a clear solution; the resulting clear solution was poured into a sealed autoclave and subjected to solvothermal pretreatment at 60°C for 24 hours; subsequently, the obtained sol was subjected to solvent volatilization treatment at 45°C for 48 hours ; Finally, the obtained solid sample was calcined at 550° C. for 5 h to remove the organic template existing in the mesoporous channels, and obtain the ordered alumina mesoporous material sample.

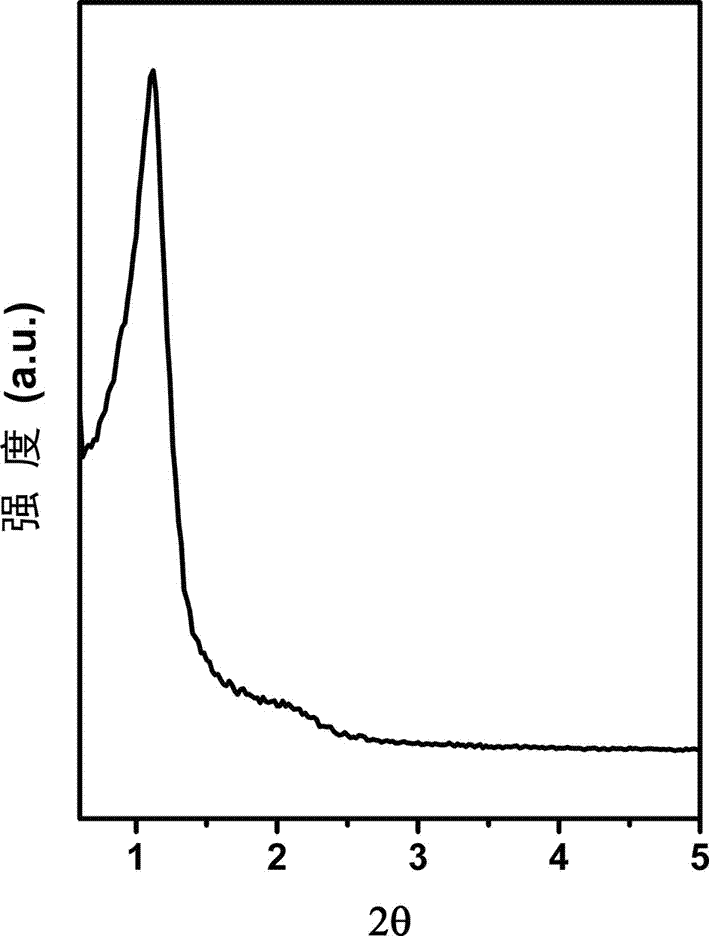

[0036] The results of XRD and nitrogen adsorption characterization show that the prepared sample has a highly regular and ordered two-dimensional hexagonal mesoporous channel structure. The specific surface area and pore volume of the sample are calculated to be 302 m 2 / g and 0.52cm 3 / g, the mesopore d...

Embodiment 3

[0041] Under strong stirring at 35°C, add 3.6g EO to 20mL absolute ethanol solution containing 1.0g glacial acetic acid and 3.0g 6M hydrochloric acid 20 PO 70 EO 20 and 4.5g of aluminum tert-butoxide, completely dissolved to obtain a clear solution; the resulting clear solution was poured into a sealed autoclave, and subjected to solvothermal pretreatment at 100°C for 24 hours; subsequently, the obtained sol was volatilized in an open state at 80°C Treat for 24 hours; finally, the obtained solid sample is calcined at 600° C. for 5 hours to remove the organic template existing in the mesoporous channel, and obtain the ordered alumina mesoporous material sample.

[0042] The results of XRD and nitrogen adsorption characterization show that the prepared sample has a highly regular and ordered two-dimensional hexagonal mesoporous channel structure. According to calculation, the specific surface area and pore volume of the sample are 350m 2 / g and 0.73cm 3 / g, the mesopore diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com