Superlong carbon chain amphiphilic waterhead-based hydrophobic monomer and preparation method thereof

A technology of amphiphilic head groups and hydrophobic monomers, which is applied in the preparation of amino hydroxyl compounds, carboxylic acid amides, chemical instruments and methods, etc. It can solve the problems of low polymerization activity, unsatisfactory association performance, and short carbon chains of hydrophobic monomers. Problems, to achieve high polymerization activity, good solubility, easy separation and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

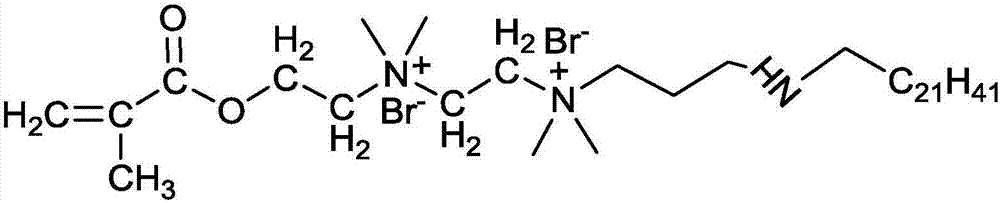

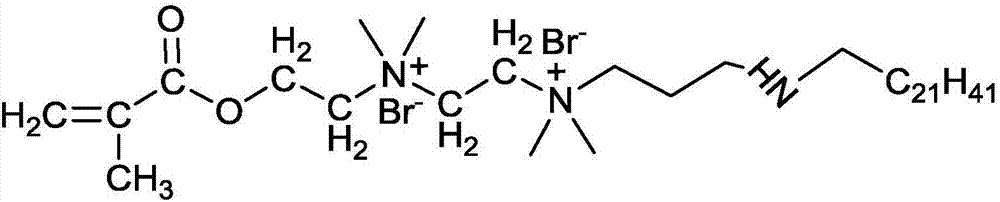

[0014] Example 1 Preparation of ultra-long carbon chain double hydrophilic head group hydrophobic monomer according to the steps

[0015] (1) Dissolve 0.2 mole of dibromoethane in acetone, add 0.1 mole of dimethylaminoethyl methacrylate dropwise to the acetone solution under stirring conditions, react at room temperature for 4 hours, and remove the solvent by distillation under reduced pressure , recrystallized with acetone to obtain N,N-dimethyl bromoethyl methacryloyloxyethyl ammonium bromide intermediate;

[0016] (2) Add 0.05 mole of the intermediate and 0.055 mole of erucamide propyl dimethyl tertiary amine to ethanol, react at room temperature for 24 hours, remove the solvent by distillation under reduced pressure, and recrystallize with acetone to obtain the ultra-long carbon chain amphiphile Hydrophobic monomers based on hydroheads.

Embodiment 2

[0017] Polymerization performance of embodiment 2 ultra-long carbon chain double hydrophilic head group hydrophobic monomer

[0018] The hydrophobic monomer with a mole fraction of 0.8% and the acrylamide with a mole fraction of 99.2% were formulated into an aqueous solution with a monomer concentration of 20%, and nitrogen gas was passed for half an hour, and the temperature was raised to 45°C and an initiator was added. The polymerization reaction was 8h, and the Ethanol is separated, purified and dried to obtain a hydrophobic association polymer. The prepared associative polymer has good associative viscosity-increasing performance, the critical association concentration is only 0.2%, and the 0.5% polymer solution is in 170s -1 The lower viscosity reaches more than 220mPa.s, and it has strong hydrophobic association performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com