Water-based aldehyde-free veneering glue for wood veneer as well as preparation method and application thereof

A veneer and glue technology, applied in the direction of adhesives, monocarboxylate copolymer adhesives, adhesive types, etc., can solve problems such as difficult cleaning, high formaldehyde content, and short timeliness, so as to reduce internal stress, Good permeability and improved aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

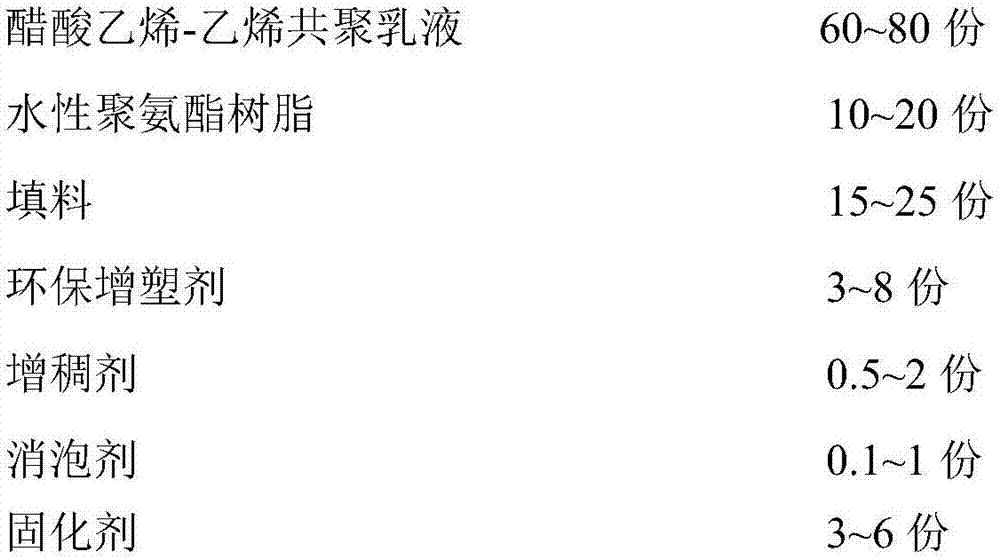

Method used

Image

Examples

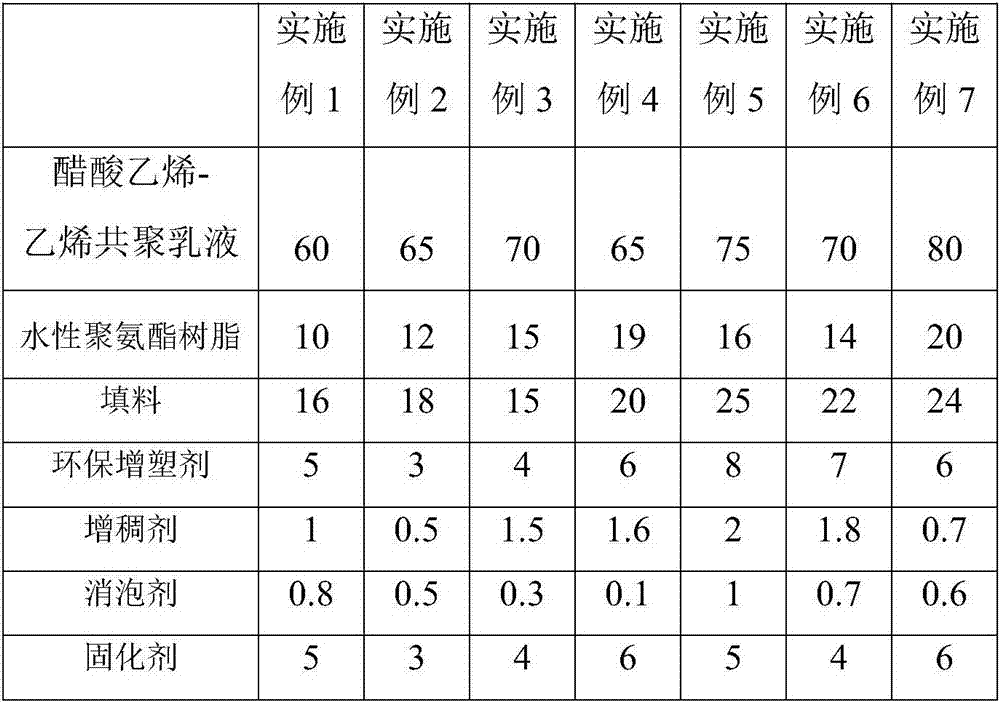

Embodiment 1

[0031] Vinyl acetate-ethylene copolymer emulsion in embodiment 1 is Germany Wacker EP724; Water-based polyurethane resin is cationic polyester type water-based polyurethane resin; Filler is glass powder; Environmental plasticizer is epoxy soybean oil; Thickener is guar Soybean gum; the defoamer is NXZ defoamer, and the curing agent is TDI.

Embodiment 2

[0032] The vinyl acetate-ethylene copolymer emulsion in embodiment 2 is DA524 of Dalian Chemical; Water-based polyurethane resin is cationic polyester type water-based polyurethane resin; Filler is heavy calcium carbonate; Environment-friendly plasticizer is TXIB; Thickener is FS22 cationic thickener Thickener; defoamer is 470 defoamer, curing agent is PMDI.

Embodiment 3

[0033] Vinyl acetate-ethylene copolymer emulsion in embodiment 3 is DA908 of Dalian Chemical; Water-based polyurethane resin is cationic polyester type water-based polyurethane resin; Filler is transparent powder; Environmental plasticizer is epoxy octyl soybean oleate; Thickener is Hydroxypropyl starch ether; the defoamer is 399 defoamer, and the curing agent is HDI.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com