Method for preparing nickel-base amorphous alloy coating

An amorphous alloy and coating technology is applied in the field of preparation of nickel-based amorphous alloy coatings, which can solve the problems of complex preparation process and high cost, and achieve the effects of simple process, few steps and controllable particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

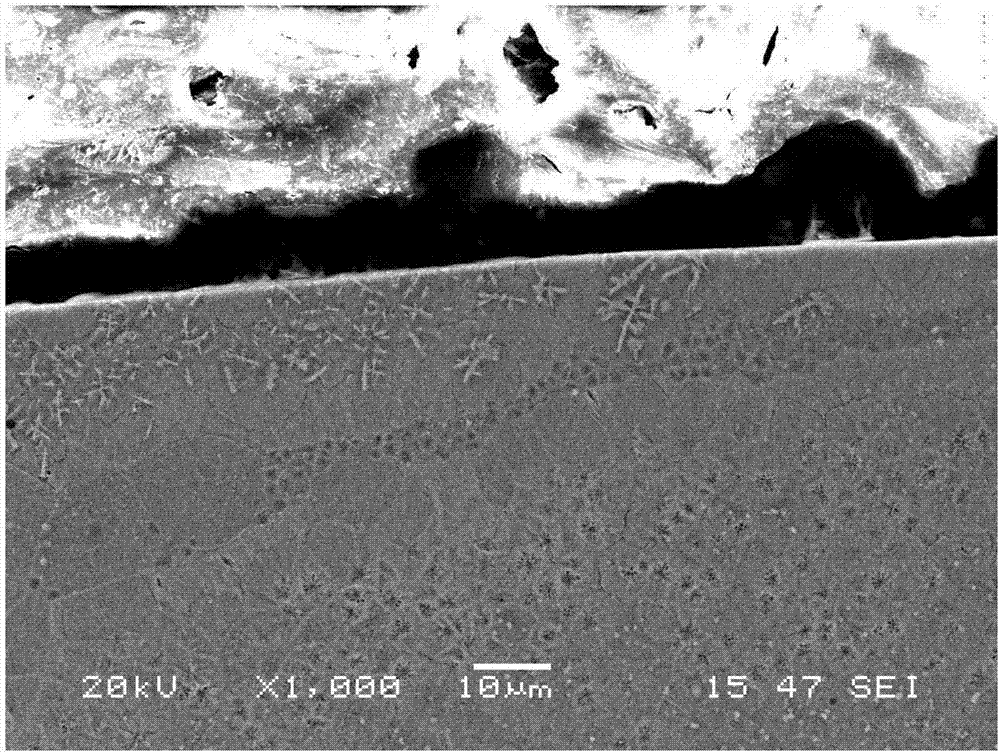

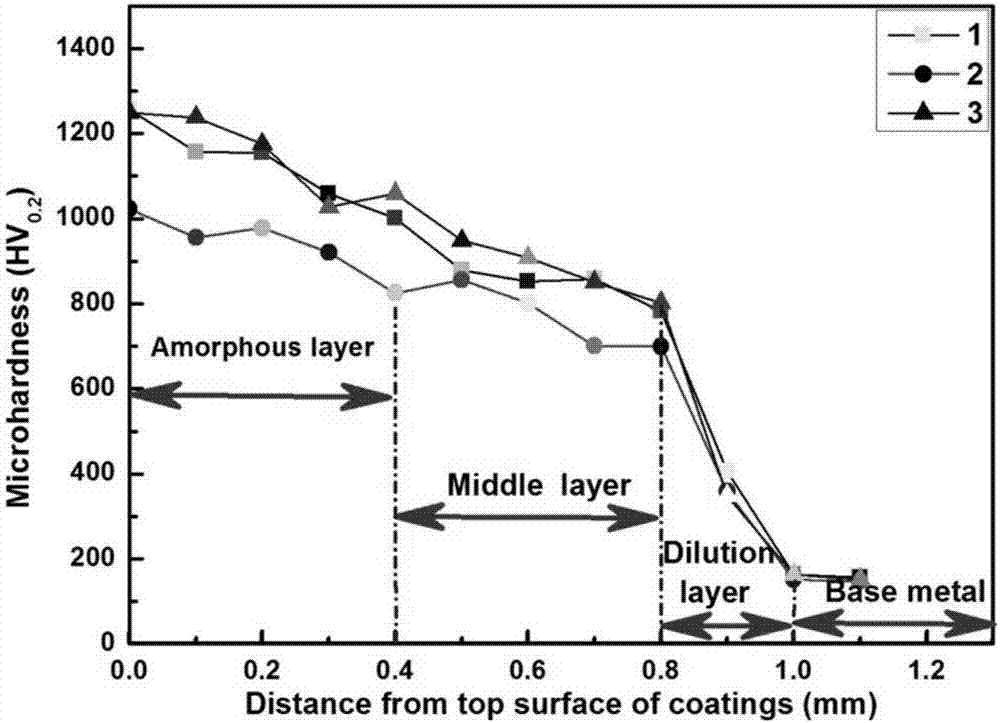

[0028] The mass percentage is: 2% gadolinium, 3% niobium, 10% boron, 12% silicon, 33% iron, 40% Ni elemental powder mixed, the particle size of each powder is between 150-200 mesh; The powder is mechanically ball milled, the speed of the ball mill is 600 rpm, and the ball milling time is 60 minutes. After the ball milling, it is dried at 150°C for 45 minutes; the nickel-based amorphous coating is directly prepared on the surface of the low alloy steel by using the simultaneous powder feeding laser cladding technology ;Laser cladding parameters are: laser power 12kW, spot diameter 1.5mm, scanning speed 8m / min, protective argon flow rate 22L / min, powder feeding rate 18g / min; the microhardness of the obtained cladding coating is as follows: figure 1 Shown in curve 1. The topography in the present embodiment is as shown in 1, from figure 1 It can be seen that the precipitated crystal phase structure appeared on the surface of the coating, and the crystal phase structure of the su...

Embodiment 2

[0030] The mass percentage is: 3 gadolinium, 3% niobium, 10% boron, 15 silicon, 34 iron, 35Ni elemental powder mixed, the particle size of each powder is between 150-200 mesh; the mixed elemental powder is mechanically ball milled, The speed of the ball mill is 600 rpm, the ball milling time is 60 minutes, and the ball milling is dried at 150°C for 45 minutes; the nickel-based amorphous coating is directly prepared on the surface of the low alloy steel by using the simultaneous powder feeding laser cladding technology; the laser cladding parameters For: the laser power is 13kW, the spot diameter is 2mm, the scanning speed is 9m / min, the protective argon gas flow rate is 22L / min, and the powder feeding rate is 18g / min; the microhardness of the obtained cladding coating is as follows: figure 1 Shown in curve 2.

Embodiment 3

[0032] The mass percentage is: 4 gadolinium, 5% niobium, 12% boron, 14% silicon, 35 iron, 30Ni mixed elemental powder, the particle size of each powder is between 150-200 mesh; the mixed elemental powder is mechanically ball milled , the speed of the ball mill is 600 rpm, the ball milling time is 60 minutes, and it is dried at 150°C for 45 minutes after ball milling; the nickel-based amorphous coating is directly prepared on the surface of low-alloy steel by using the synchronous powder feeding laser cladding technology; laser cladding The parameters are: laser power 12kW, spot diameter 1.5mm, scanning speed 8m / min, protective argon gas flow rate 22L / min, powder feeding volume 18g / min; the microhardness of the obtained cladding coating is as follows: figure 1 Shown in curve 3.

[0033] In summary, the cladding coating material prepared in this example has a very high hardness, reaching about 1200HV, and the average hardness obtained by the coating in Example 1 is the highest, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com