Method for recycling metal in waste lithium iron phosphate batteries

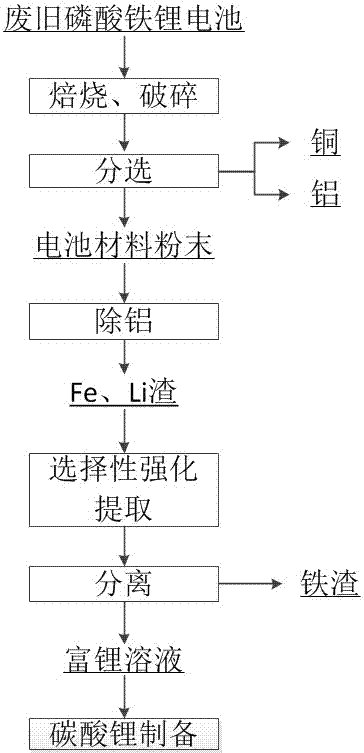

A technology for lithium iron phosphate batteries and waste batteries, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve the problems of limited practical application, high energy consumption process, long process flow, etc., to simplify the recycling process, The effect of high efficiency and a wide range of pharmaceutical sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Break the positive electrode material of the waste lithium iron phosphate battery into pieces of 1~20mm×1~20mm, and roast at 800°C for 2 hours. During the roasting process, CaO can be sprayed to prevent the generation of fluorine-containing gas. The mass ratio of body is controlled at 300:1. After the calcination, metals such as aluminum and copper are removed by sieving to obtain lithium-containing powder.

[0064] Table 1 Composition of lithium-containing powder obtained by roasting and sorting lithium iron phosphate batteries (wt%)

[0065] Fe P Li 23.2 12.4 2.1

[0066] (2) The battery material powder containing aluminum, iron, and lithium obtained by roasting and sorting waste batteries is added to NaOH alkali solution to dissolve aluminum and aluminum oxides to obtain iron-containing lithium residues. The concentration of NaOH lye is 2mol / L.

[0067] (3) The obtained iron-containing lithium-containing residue is ball milled to obtain ...

Embodiment 2

[0072] Table 2 Composition of lithium-containing powder obtained by roasting and sorting lithium iron phosphate batteries (wt%)

[0073] Fe P Li 27.2 14.4 3.1

[0074] (2) The battery material powder containing aluminum, iron and lithium obtained by roasting and sorting the waste battery is added to the Ca(OH) 2 In the alkaline solution, aluminum and aluminum oxides are dissolved to obtain a residue containing iron and lithium. Ca(OH) 2 The concentration of lye is 2mol / L.

[0075] (3) The obtained iron-containing lithium-containing residue is ball milled to obtain iron-containing lithium-containing powder passed through a 200-mesh sieve, and the ball milling time is 2 hours.

[0076] (4) The obtained lithium-containing powder is intensively leached in a mixed solution of ammonium salt and ammonia, the ammonium salt concentration is 3mol / L, the leaching S / L is 80g / L, the leaching temperature is 40°C, the leaching time is 20min, and the leaching is st...

Embodiment 3

[0079] (1) Break the positive electrode material of the waste lithium iron phosphate battery into pieces of 1~20mm×1~20mm, roast at 800°C for 2 hours, and spray CaCO during the roasting process 3 To prevent the generation of fluorine-containing gas, the mass ratio of battery waste to calcium-containing powder is controlled at 300:1. After the calcination, metals such as aluminum and copper are removed by sieving to obtain lithium-containing powder.

[0080] Table 3 Composition of lithium-containing powder obtained by roasting and sorting lithium iron phosphate batteries (wt%)

[0081] Fe P Li 23.5 10.1 1.7

[0082] (2) The battery material powder containing aluminum, iron and lithium obtained by roasting and sorting the waste battery is added to the Ca(OH) 2 In the alkaline solution, aluminum and aluminum oxides are dissolved to obtain a residue containing iron and lithium. Ca(OH) 2 The concentration of lye is 2mol / L.

[0083] (3) The obtained iron-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com