Elemental bismuth catalyst for electrochemical reduction of carbon dioxide as well as preparation and application of elemental bismuth catalyst

A carbon dioxide and catalyst technology, which is applied to the preparation and application of carbon dioxide electrochemical reduction catalysts, can solve problems such as rare research reports, and achieve the effects of reducing mass transfer resistance, good application prospects and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

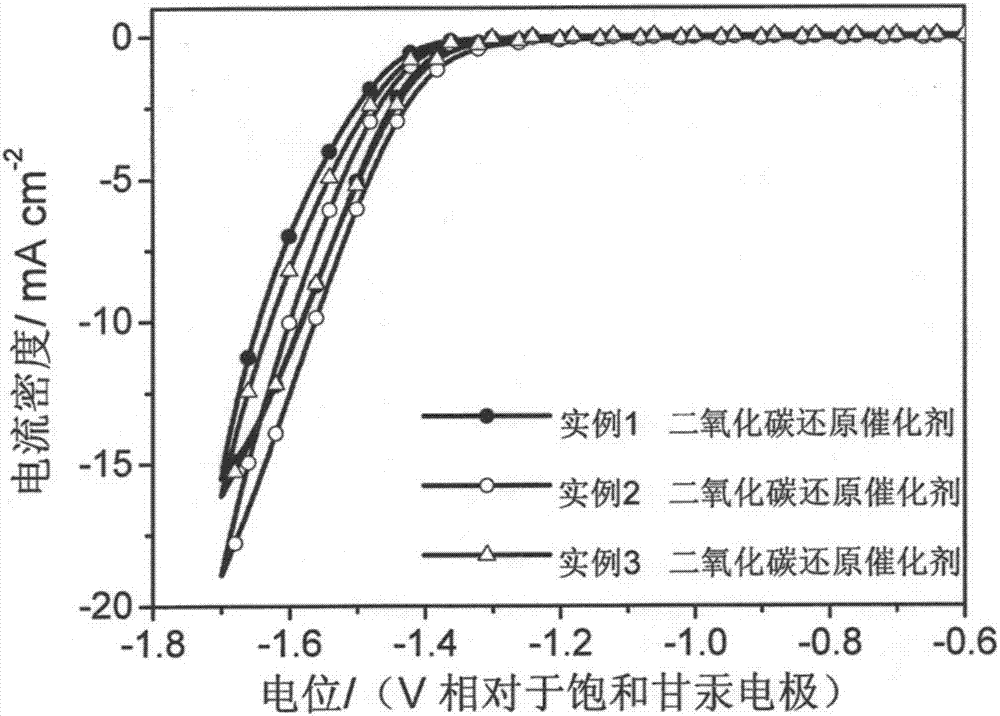

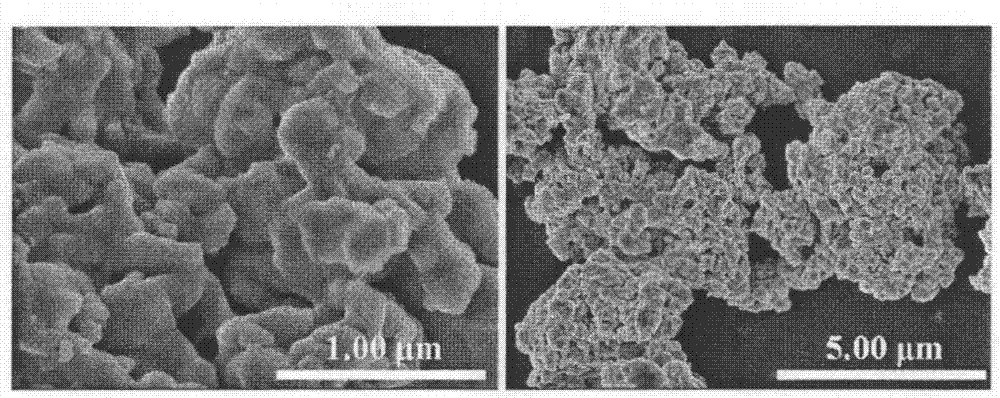

Embodiment 1

[0035] A carbon dioxide electrochemical reduction catalyst includes a micro-nano-level elemental metal bismuth catalyst synthesized by an aqueous chemical reduction method. The preparation method of the electrochemical reduction catalyst for carbon dioxide is as follows: Weigh 2.5 mmol of bismuth nitrate pentahydrate and add it to a beaker, add 10 mL of deionized water and 0.5 mL of concentrated nitric acid (with a concentration of 14.4 M), magnetically stir for 2 hours, make The bismuth nitrate and nitric acid are dissolved in deionized water to obtain a catalyst precursor solution; the solution is transferred to a three-necked flask, and the mixed solution is condensed and refluxed in an oil bath. When the temperature rises to 100℃, add 30mL 8.5M N 2 H 4 ·H 2 O was reduced, and the temperature was kept at 100°C for 30 minutes. After the reaction is over, cool naturally, and the obtained solids were washed with deionized water and absolute ethanol to neutrality and centrifuged...

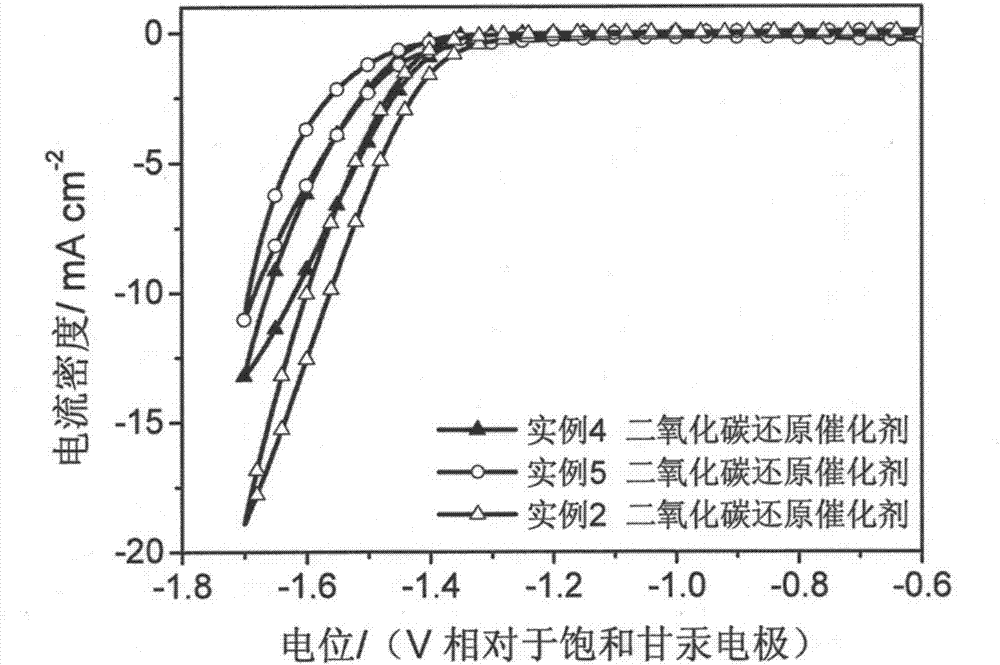

Embodiment 2

[0037] A carbon dioxide electrochemical reduction catalyst includes a micro-nano elemental metal bismuth catalyst synthesized by a chemical reduction method of aqueous solution. The preparation method of the electrochemical reduction catalyst for carbon dioxide is as follows: Weigh 2.5 mmol of bismuth nitrate pentahydrate and add it to a beaker, add 10 mL of deionized water and 0.5 mL of concentrated nitric acid (with a concentration of 14.4 M), magnetically stir for 2 hours, make The bismuth nitrate and nitric acid are dissolved in deionized water to obtain a catalyst precursor solution; the solution is transferred to a three-necked flask, and the mixed solution is condensed and refluxed in an oil bath. When the temperature rises to 100℃, add 30mL 8.5MN 2 H 4 ·H 2 O was reduced, and the temperature was kept at 100°C for 45 minutes. After the reaction is over, cool naturally, and the obtained solids were washed with deionized water and absolute ethanol to neutrality and centrif...

Embodiment 3

[0039] A carbon dioxide electrochemical reduction catalyst includes a micro-nano elemental metal bismuth catalyst synthesized by a chemical reduction method of aqueous solution. The preparation method of the electrochemical reduction catalyst for carbon dioxide is as follows: Weigh 2.5 mmol of bismuth nitrate pentahydrate and add it to a beaker, add 10 mL of deionized water and 0.5 mL of concentrated nitric acid (with a concentration of 14.4 M), magnetically stir for 2 hours, make The bismuth nitrate and nitric acid are dissolved in deionized water to obtain a catalyst precursor solution; the solution is transferred to a three-necked flask, and the mixed solution is condensed and refluxed in an oil bath. When the temperature rises to 100℃, add 30mL 8.5MN 2 H 4 ·H 2 O was reduced, and the temperature was kept at 100°C for 60 minutes. After the reaction is over, cool naturally, and the obtained solids were washed with deionized water and absolute ethanol to neutrality and centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com