Method for preparing polyester by ring-opening polymerization

A technology of ring-opening polymerization and polyester, applied in the field of organometallic catalyzed polymer materials, can solve problems such as being unsuitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

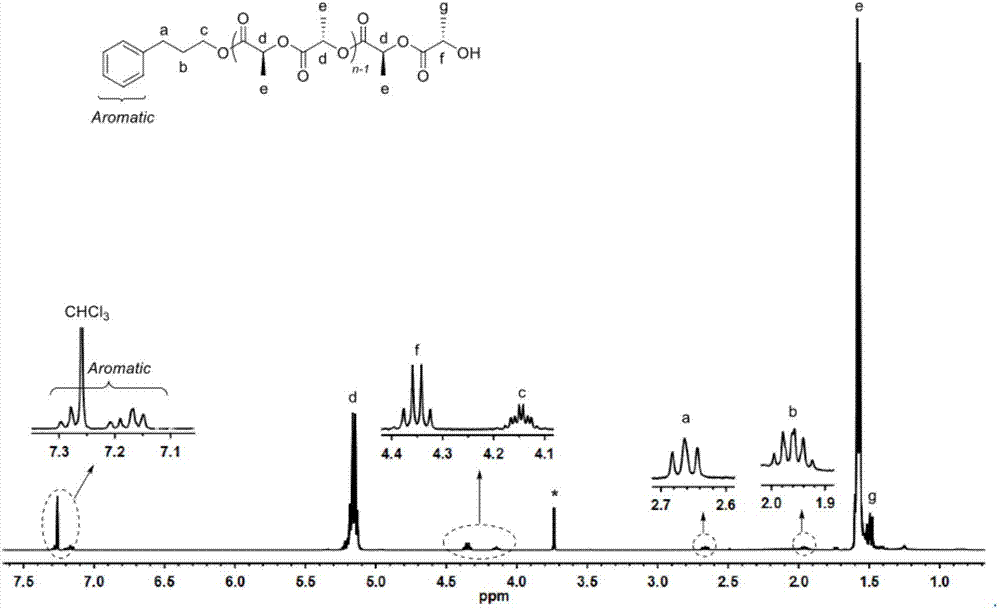

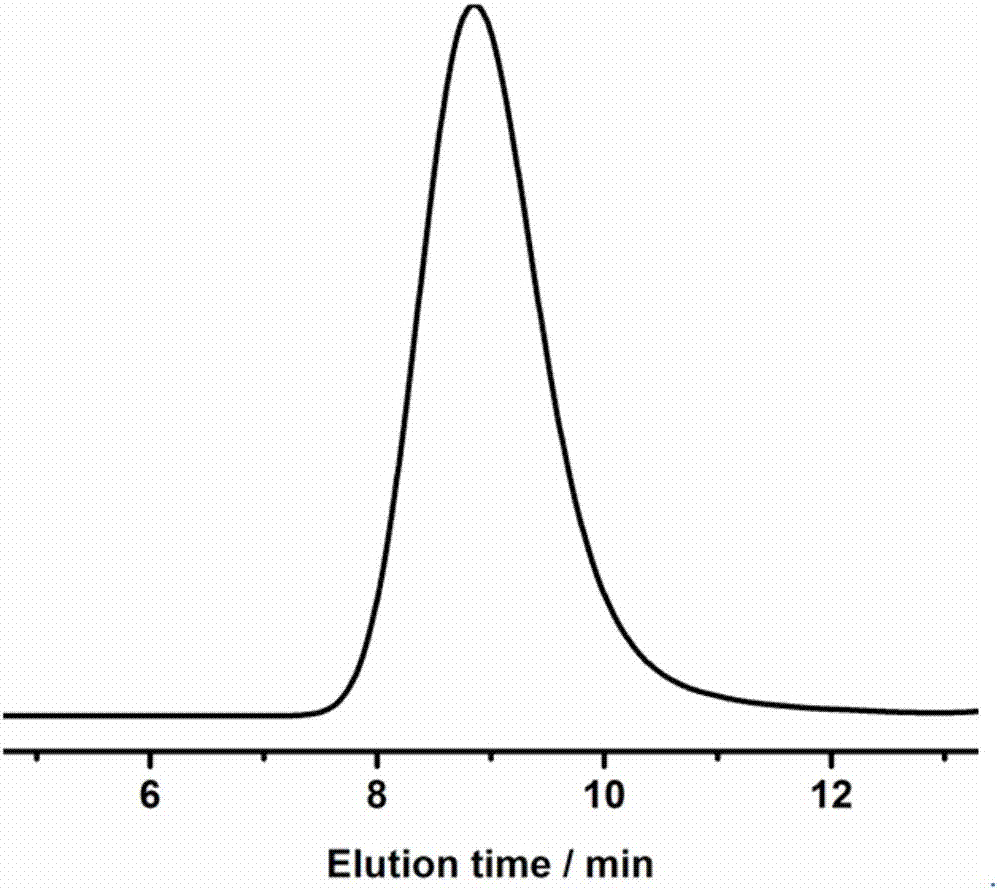

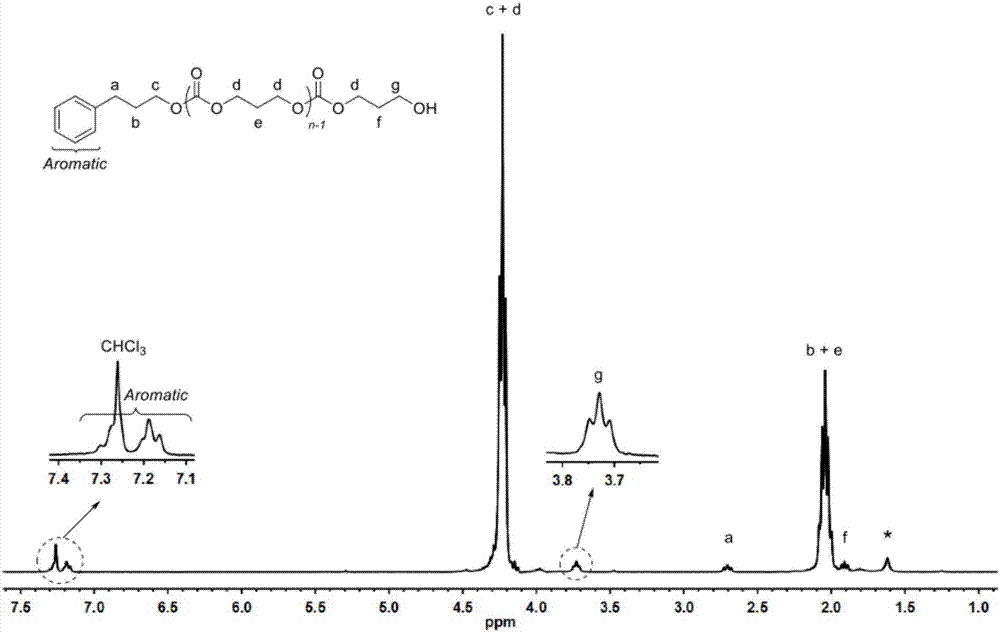

[0072] In a 10mL polymerization tube, add L-lactide (0.432g, 3mmol), compound (1) (0.022g, 0.1mmol), phenylpropanol (13.5μL, 0.1mmol), and stir magnetically at 130°C After 24 hours, the reaction was stopped, and a small amount of dichloromethane was added dropwise to the resulting mixture to dissolve, and then the resulting solution was slowly dropped into cold methanol, and a white polymer was precipitated. After centrifugation and vacuum drying, 0.38 g of the product was obtained, and the conversion rate was 98.7%. Number average molecular weight M of poly L-lactide n It is 4560g / mol, and the molecular weight distribution PDI is 1.18. (attached figure 1 , 2 )

Embodiment 2

[0074] In a 10mL polymerization tube, add D-lactide (0.432g, 3mmol), compound (8) (0.027g, 0.1mmol), pentaerythritol (9.7μL, 0.1mmol), and stir magnetically at 130°C for 20 hours , stop the reaction, drop a small amount of dichloromethane into the resulting mixture to dissolve, then slowly drop the resulting solution into cold methanol, a white polymer is precipitated, and obtain 0.29g of the product through centrifugation and vacuum drying, with a conversion rate of 96.1%. - Number average molecular weight M of lactide n It is 4610 g / mol, and the molecular weight distribution PDI is 1.19.

Embodiment 3

[0076] In a 10mL polymerization tube, add L-lactide (0.432g, 3mmol), compound (9) (0.058g, 0.1mmol), benzyl alcohol (10.0μL, 0.1mmol), and stir magnetically at 130°C for 18 After hours, the reaction was stopped, and a small amount of dichloromethane was added dropwise to dissolve the resulting mixture, and then the resulting solution was slowly dripped into cold methanol, and a white polymer was precipitated. After centrifugation and vacuum drying, 0.36g of the product was obtained, and the conversion rate was 98.4%. Number average molecular weight M of L-lactide n It is 4710g / mol, and the molecular weight distribution PDI is 1.18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com