Method for preparing silicon carbide ohmic contact by adopting ion implantation enhanced laser annealing

A technology of ohmic contact and ion implantation, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of poor process control, uneven ohmic contact resistivity, high ohmic contact resistivity, etc., to reduce resistivity, Reduce process control issues and improve performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

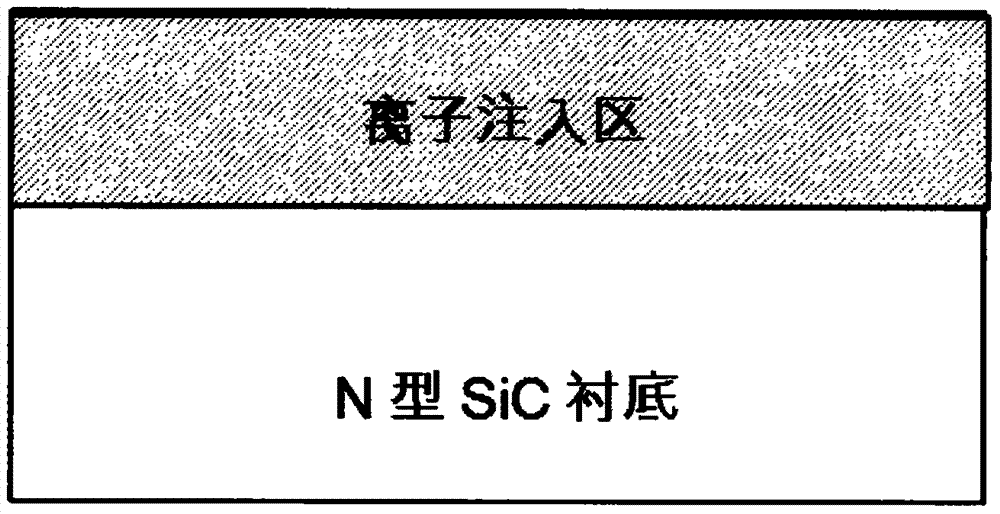

[0025] First, at the bottom of the N-type SiC substrate, a heavily doped region with a depth of 0.2 μm and a doping concentration of 1E20cm-3 is formed by ion implantation of N. The doping type of the part required to form an ohmic contact can be n-type doping , can also be P-type doping, and the doping type formed by the implanted ions is the same as the original doping type. For example: if the ohmic contact part is originally N-type doped, the implanted ions are one or more of N, P, As, etc. implanted together; if the ohmic contact part is originally P-type doped, the implanted ions are B, P, As, etc. One or more co-implantation of Al, etc.; ion implantation can be single-energy ion implantation or multiple-energy ion implantation, the depth of the heavily doped region formed after the ion implantation ranges from 0.01-1 μm, and the heavily doped Zone concentration range is 1E17cm -3 -5E21cm -3 , as attached figure 1 shown.

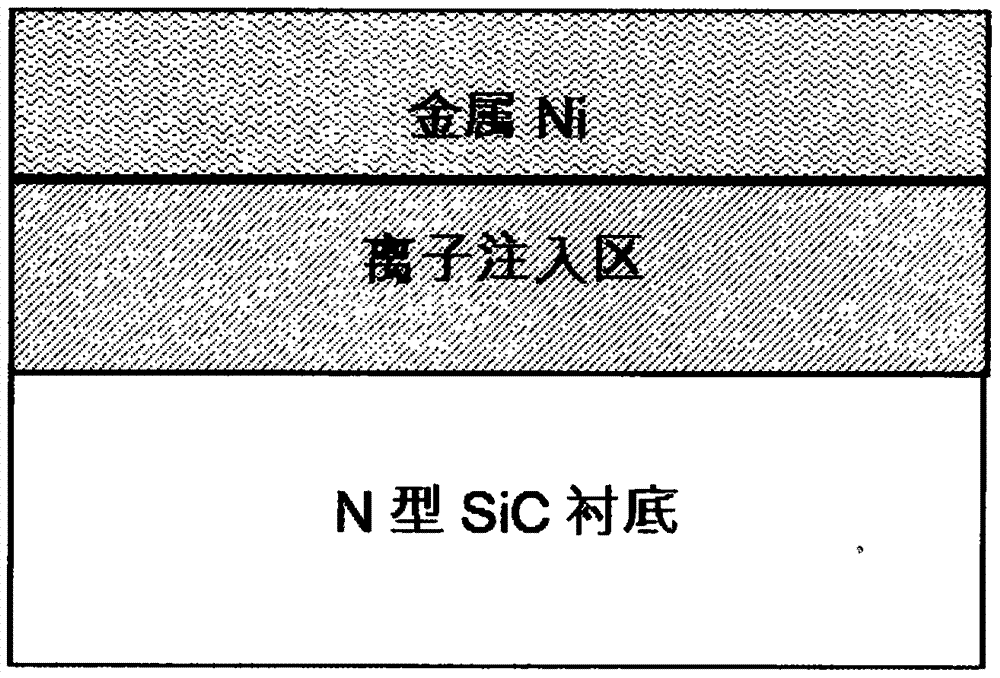

[0026] Then, a layer of Ni with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com