Graphite intercalation compound preparation method

A graphite interlayer and compound technology, applied in the direction of graphite, zinc halide, copper halide, etc., can solve the problems of different physical and chemical properties, different application fields, etc., achieve good process repeatability, reduce production costs, and improve electronic conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

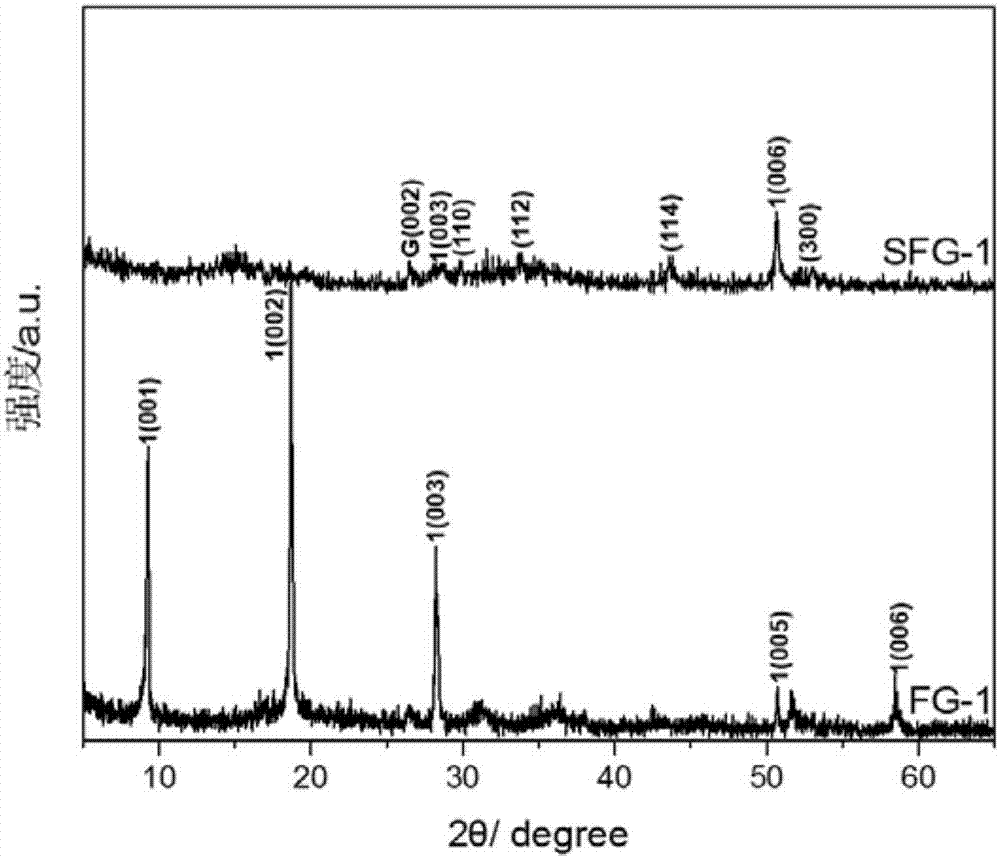

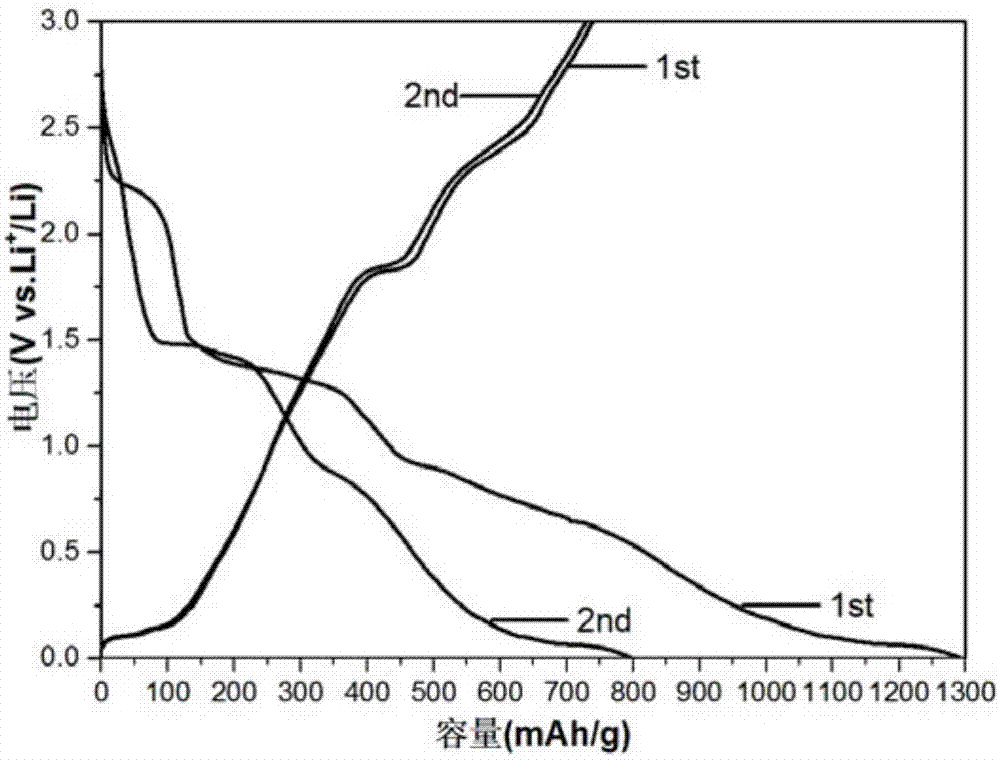

[0016] A kind of preparation method of the graphite intercalation compound of metal salt as intercalation agent, comprises: 1g particle size is the natural graphite of 10 μ m after drying 4h at 120 ℃, after adding 3.4g anhydrous ferric chloride rapidly, then stirring and mixing in the air, Then vacuum-dried at 120° C. for 1 hour and then transferred to a reaction kettle. After sealing the reaction kettle in the air, it was placed in a heating furnace and heated to 450° C. and kept for 48 hours. The obtained product was washed with deionized water, alcohol and acetone and dried at 80 °C for 12 h to obtain a first-order FeCl 3 -graphite intercalation compound (as attached figure 1 Shown), the sample is named FG-1 (F ferric chloride, -2 first order). Take 0.3g of the FG-1 prepared above in CS 2 Heating it to 550°C at a heating rate of 5°C / min in the mixture with nitrogen gas and holding it for 2 hours to prepare a graphite intercalation compound intercalated with iron sulfide, ...

Embodiment 2

[0020] Dry 1g of natural graphite with a particle size of 10μm at 100°C for 4h, then quickly add 1.7g of anhydrous ferric chloride, stir and mix in the air, then dry it in vacuum at 100°C for 1h, and then transfer it to the reactor. After the gloves are sealed in the air, place them in a heating furnace and heat them to 450°C and keep them warm for 24 hours. The obtained product was washed with deionized water, alcohol and acetone and dried at 80 °C for 12 h to obtain the second-order FeCl 3 - Graphite interlayer compound, the sample is named FG-2 (F ferric chloride, -2 second order);

[0021] Take 0.5g of FG-2 and treat it under the mixed gas of hydrogen and argon at 450°C for 4 hours to obtain RFG-2 (R hydrogen reduction). Take 0.3g of RFG-2 and 0.6g of elemental sulfur in the air and mix them in the reaction kettle. Heat to 155°C and keep it for 12h, then raise the temperature to 350°C and keep it for 2h to make sulfur react with elemental metal to form sulfide. Finally, ...

Embodiment 3

[0023] Dry 1g of natural graphite with a particle size of 10μm at 120°C for 4h, then quickly add 6.8g of anhydrous ferric chloride, stir and mix in the air, then dry it in vacuum at 120°C for 1h, and then transfer it to the reactor. After sealing in the air, place it in a heating furnace and heat it to 450°C and keep it warm for 12 hours. The obtained product was washed with deionized water, alcohol and acetone, dried at 80°C for 12 hours, and collected for later use. The sample was named FG-1 (F ferric chloride, -1 first order). Take 0.3g of the above-prepared FNG-1 and heat it to 550°C at a heating rate of 5°C / min in a mixed atmosphere of hydrogen sulfide and nitrogen, and keep it warm for 2 hours to prepare an iron sulfide intercalated graphite intercalation compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com