Preparation method of super-weather-resistance polysiloxane modified resin and finish paint

A technology of siloxane modification and acrylic resin, applied in the direction of coating, can solve the problems of high labor cost and environmental pollution, and achieve the effect of high molecular weight and good weather resistance of paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

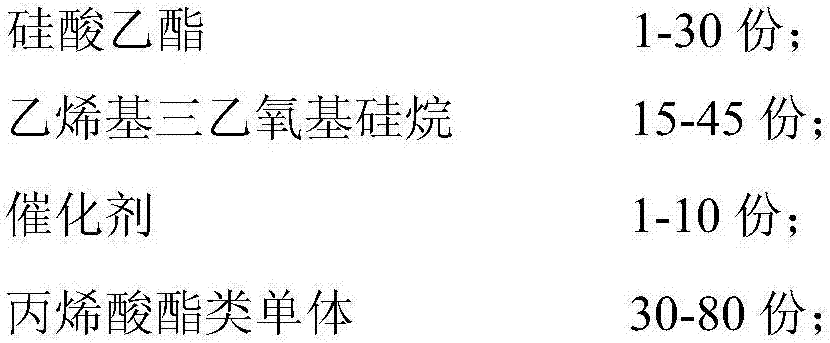

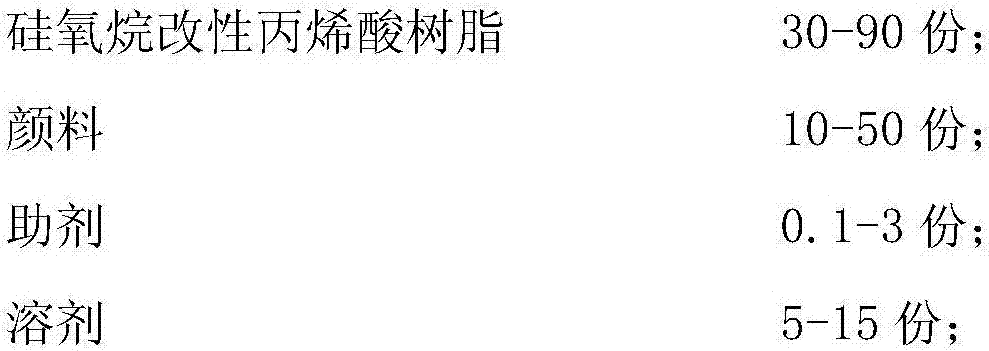

[0025] The formulation components and mass percentages of the super weather-resistant siloxane-modified acrylic resin used in the present invention are shown in Table 1.

[0026] The preparation method of super weather-resistant siloxane modified acrylic resin embodiment 1 to embodiment 3 in the present invention is as follows:

[0027] Add the components of ethyl silicate and vinyl triethoxysilane into the reaction flask, mix well, and raise the temperature to 70-75°C, keeping the temperature constant. Catalyst is prepared according to the formula quantity of water and hydrochloric acid. Then slowly and continuously add the catalyst, react for 2-2.5 hours, and then distill under reduced pressure to remove ethanol and low boilers to obtain a polysiloxane prepolymer.

[0028] Nitrogen gas is blown in, and the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com