Method for preparing polyimide fiber by combining three-step method and imidization

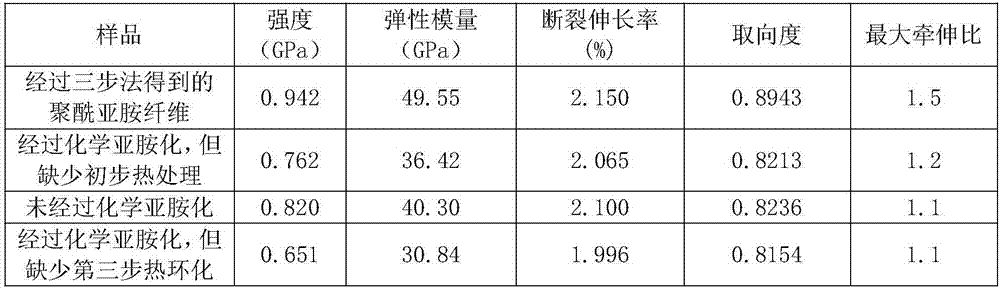

A polyimide fiber, imidization technology, applied in the field of materials, can solve the problems of low imidization degree of polyimide fiber, fiber surface defects, fiber performance degradation, etc., to improve the imidization degree, fiber The effect of improving the degree of orientation and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

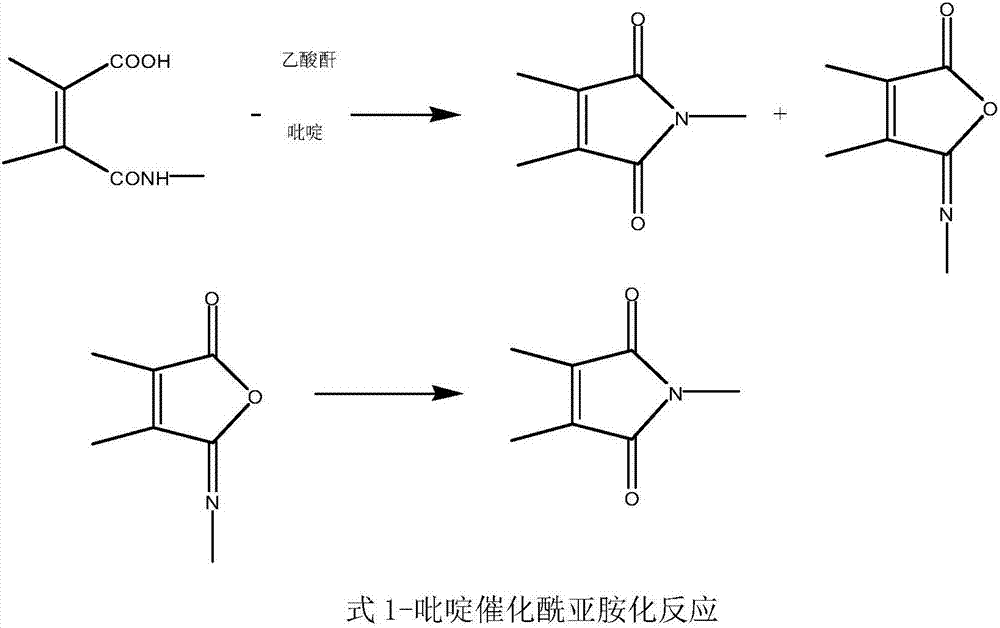

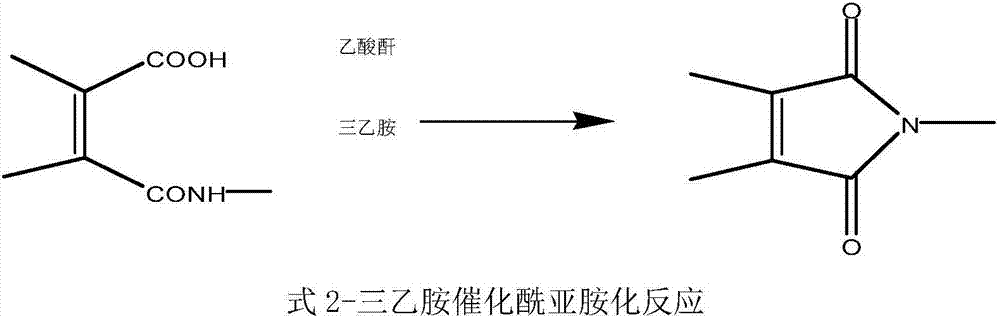

Method used

Image

Examples

Embodiment 1

[0033] (1) PMDA and ODA are added in the NMP solvent, stirred, condensation polymerization takes place, obtains polyamic acid spinning solution, solid content is 5%;

[0034] (2) The polyamic acid spinning solution is spun according to the wet spinning process, and the spinning solution is directly passed through the coagulation bath (the volume fraction of DMAc is 5%) after being extruded from the spinneret under the nitrogen pressure of 0.3MPa, Wash with water, and dry the polyamic acid precursor fibers through a tube furnace at 100°C at a constant speed for 3 minutes;

[0035] (3) Pass the polyamic acid precursor fibers through a tube furnace at 150°C at a constant speed for 2 minutes to obtain partially imidized fibers;

[0036] (4) The above-mentioned fibers were soaked in a solution of 1:1 of acetic anhydride / pyridine for 16 hours to perform chemical imidization;

[0037] (5) Dry the fiber obtained in the previous step through a tube furnace at 100°C at a uniform speed ...

Embodiment 2

[0042] (1) BPDA and ODA are added to the DMAc solvent, stirred, and condensation polymerization takes place to obtain a polyamic acid spinning solution with a solid content of 20%;

[0043] (2) The polyamic acid spinning solution is spun according to the wet spinning process, and the spinning solution is directly passed through the coagulation bath (the volume fraction of DMAc is 6%) after being extruded from the spinneret under the nitrogen pressure of 0.2MPa, Wash with water, and dry the polyamic acid precursor fibers through a tube furnace at 60°C at a constant speed for 3 minutes;

[0044] (3) Pass the polyamic acid precursor fibers through a tube furnace at 260°C at a constant speed for 2 minutes to obtain partially imidized fibers;

[0045] (4) Soak the above fibers in a solution of acetic anhydride / pyridine at a ratio of 1:1 for 12 hours for chemical imidization;

[0046](5) Dry the fiber obtained in the previous step through a tube furnace at 60°C at a uniform speed f...

Embodiment 3

[0052] (1) Add the BPDA / PDA / ODA ratio of 10 / 7 / 3 into the DMAc solvent, stir, and undergo condensation polymerization to obtain a polyamic acid spinning solution with a solid content of 10%;

[0053] (2) The polyamic acid spinning solution is spun according to the wet spinning process, and the spinning solution is directly passed through the coagulation bath (the volume fraction of DMAc is 7%) after being extruded from the spinneret under the nitrogen pressure of 0.25MPa, Washing with water, passing the polyamic acid precursor fiber through a tube furnace at 80°C at a constant speed for 2 minutes;

[0054] (3) Pass the polyamic acid precursor fibers through a tube furnace at 260°C at a constant speed for 1 min to obtain partially imidized fibers;

[0055] (4) Soak the above fibers in a solution of acetic anhydride / pyridine at a ratio of 2:1 for 16 hours to carry out chemical imidization;

[0056] (5) Dry the fiber obtained in the previous step through a tube furnace at 80°C at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com