Fiber cladding power filter and manufacturing method thereof

A technology for optical fiber cladding and manufacturing methods, which is applied in the field of cladding power filters, can solve problems such as hot spots, property changes, filter stability, and reliability are greatly affected, and achieve improved strength and bending toughness , Guarantee the effect of safe work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

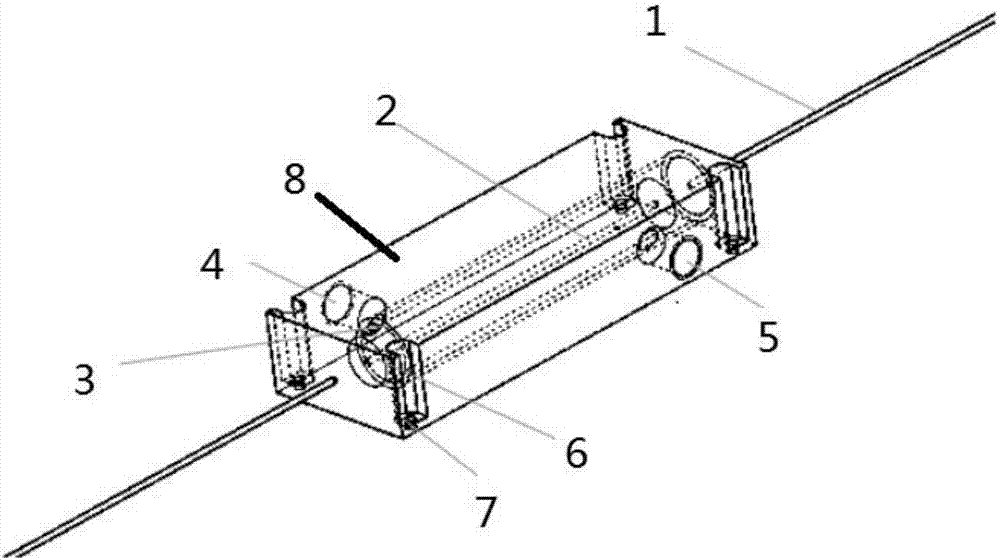

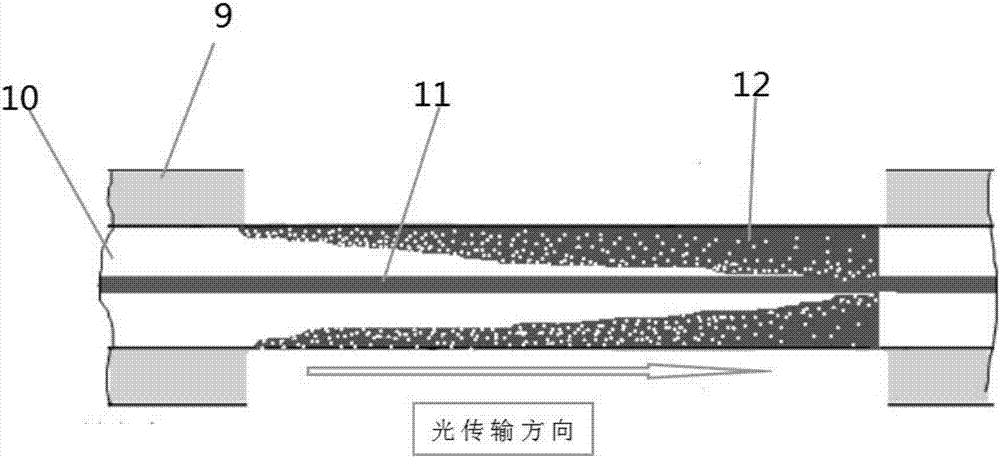

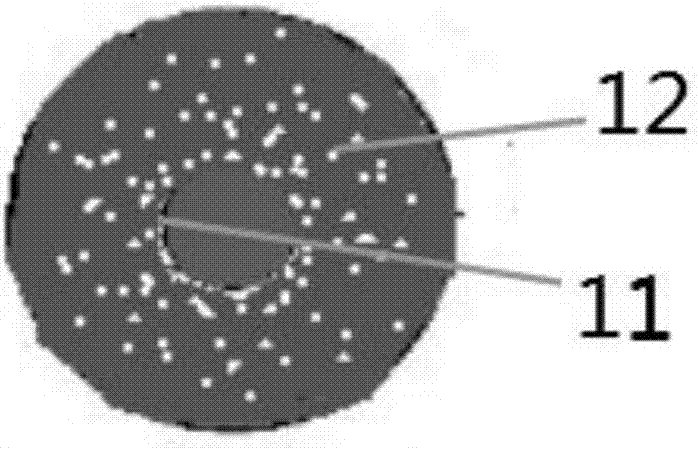

[0026] like Figure 1-3 As shown, a fiber cladding power filter, its principle is: the residual pump light and high-order laser light in the inner cladding of the optical fiber will leak out after treatment, and the light energy will be converted into heat energy on the surface of the inner hole of the heat sink. Then the water in the water channel will conduct the heat away; specifically, the optical fiber cladding power filter includes a double-clad optical fiber (1) and a heat sink (8) to filter cladding light, and the heat sink ( 8) There is an inner hole inside, and the inner hole is air or liquid. The light leaked from the optical fiber will be converted into heat energy at the interface between the inner hole and the air or liquid, without increasing the surface temperature of the optical fiber, ensuring that the optical fiber will not Melted and destroyed due to high temperature; a water channel layer (3) is provided around the inner hole, and the side wall of the heat...

Embodiment 2

[0029] like Figure 1-3 Shown, the manufacturing method of optical fiber cladding power filter comprises the steps:

[0030] S1: Stripping a section of the outer cladding (9) of the double-clad optical fiber (1) to be filtered to expose the inner cladding (10);

[0031] S2: processing the exposed inner cladding (10), immersing the exposed inner cladding (10) in nitrate powder containing low polarizability ions;

[0032] S3: heating the exposed inner cladding (10) treated in S2;

[0033] S4: Encapsulating the double-clad optical fiber after the thermal diffusion treatment in step S3 into a heat sink (8).

[0034] After the treatment in step S2, place the exposed inner cladding (10) in liquid or air and coat the tail end of the exposed inner cladding (10) with UV glue.

[0035] In step S2, the polarizability ion of the nitrate powder is 0.003C·m2 / V.

[0036] In step S3, when heating, the double-clad optical fiber is placed in a high-temperature-resistant crucible, and then t...

Embodiment 3

[0041] like Figure 1-3 Shown, the manufacturing method of optical fiber cladding power filter comprises the steps:

[0042] S1: Stripping a section of the outer cladding (9) of the double-clad optical fiber (1) to be filtered to expose the inner cladding (10);

[0043] S2: processing the exposed inner cladding (10), immersing the exposed inner cladding (10) in nitrate powder containing low polarizability ions;

[0044] S3: heating the exposed inner cladding (10) treated in S2;

[0045] S4: Encapsulating the double-clad optical fiber after the thermal diffusion treatment in step S3 into a heat sink (8).

[0046] After the treatment in step S2, place the exposed inner cladding (10) in liquid or air and coat the tail end of the exposed inner cladding (10) with UV glue.

[0047] In step S2, the polarizability ion of the nitrate powder is 0.035C·m2 / V.

[0048] In step S3, when heating, the double-clad optical fiber is placed in a high-temperature-resistant crucible, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com