Lithium ion battery composite negative pole piece with high specific energy and lithium ion battery thereof

A lithium-ion battery and negative pole piece technology, which is applied in non-aqueous electrolyte battery electrodes, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of poor uniformity of lithium supplementation of lithium powder, reduced compaction density, and high lithium-ion batteries. , to achieve the effects of improving efficiency and safety performance, increasing energy density, and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

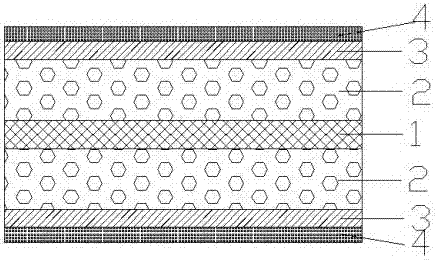

Image

Examples

Embodiment 1

[0020] A preparation method of a high specific energy lithium-ion battery composite negative pole piece, the steps are:

[0021] 1. First, weigh 3g of LA132 binder and dissolve it in 150g of twice distilled water to disperse evenly, add 3g of carbon nanotubes and disperse evenly, add 94g of hard carbon, and disperse evenly at high speed to obtain active material slurry A for future use;

[0022] 2. Weigh 60g of polyalkylene carbonate, dissolve it in 500ml of carbon tetrachloride and disperse evenly, then add 40g of ammonium triacrylonitrile pyrophosphate and disperse evenly by ultrasonic to obtain protective solution B for future use;

[0023] 3. Coat the active material slurry A on the surface of mesh copper foil (50% porosity, 20 μm thickness) through a high-precision coating machine, and obtain pole roll C after drying; then use a roller press for preheating, Heating to 120°C, passing the grid-shaped lithium sheet (80% porosity, 5mm thickness) and the pole roll C through a ...

Embodiment 2

[0026] 1. First, weigh 1g of sodium alginate binder and dissolve it in 150g of twice distilled water to disperse evenly, add 4g of graphene and disperse evenly, add 95g of hard carbon, and disperse evenly at high speed to obtain active material slurry A for future use ;

[0027] At the same time, 40g of polyalkylene oxide was weighed and dissolved in 500ml of carbon tetrachloride to disperse evenly, then add 60g of ammonium polyphosphate and ultrasonically disperse evenly to obtain protective solution B for subsequent use;

[0028] 2. After that, the active material slurry A is coated on the surface of the mesh copper foil (porosity 40%, thickness 30 μm) by a high-precision coating machine, and after drying, a pole roll C is obtained; then preheated by a roller press , heated to 80°C, and the grid-shaped lithium sheet (porosity 70%, thickness 10mm) and the pole roll C are passed through a roller press, and the grid-shaped lithium sheet is pressed on the middle surface of the p...

Embodiment 3

[0031] 1. First weigh 5g of LA132 binder and dissolve it in 150g of twice distilled water to disperse evenly, add 5gSP conductive agent and disperse evenly, add 90g of hard carbon, and disperse evenly at high speed to obtain active material slurry A for future use;

[0032] 2. At the same time, weigh 80g of polyalkylmethacrylate and dissolve it in 500ml of carbon tetrachloride to disperse evenly, then add 20g of melamine polyphosphate and ultrasonically disperse evenly to obtain protective solution B for future use;

[0033] 3. Coat the active material slurry A on the surface of mesh copper foil (porosity 60%, thickness 10 μm) through a high-precision coating machine, and after drying, obtain a pole roll C; then use a roller press for preheating, Heating to 150°C, passing the grid-shaped lithium sheet (90% porosity, 1mm thickness) and the pole roll C through a roller press, pressing the grid-shaped lithium sheet on the middle surface of the pole roll C, and obtaining the pole r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com