Treating agent for biorefractory substances in high-salinity organic wastewater

A technology for refractory biodegradable and organic wastewater, applied in the field of new oxidants, can solve problems such as poor treatment effects (such as iron-carbon micro-electrolysis and high-salt environment), achieve COD value reduction, obvious degradation ability, and demonstrate the effect of technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

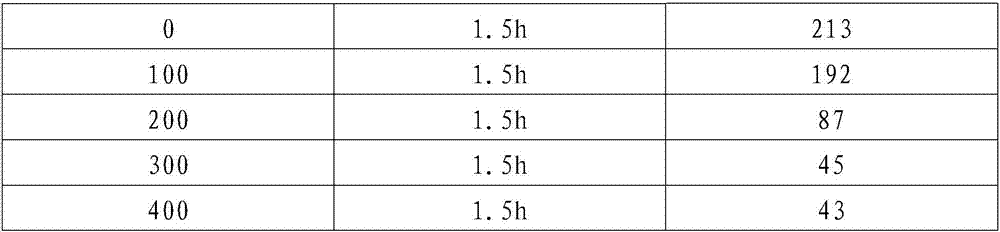

[0029] The raw materials are prepared in parts by weight, and are composed of two components A and B, wherein component A consists of 20-50 parts of sulfuric acid, 10-20 parts of o-iodobenzoic acid, 10-20 parts of potassium bromate, 10-20 parts Potassium iodate, 20-50 parts of water; the best preparation is: 30 parts of sulfuric acid, 15 parts of o-iodobenzoic acid, 10 parts of potassium bromate, 10 parts of potassium iodate, 35 parts of water. Preparation: Add sulfuric acid and o-iodobenzoic acid to a 500mL three-necked flask. The temperature of the system was controlled at 45°C, and potassium bromate and potassium iodate were added in batches under mechanical stirring. After the addition, the temperature of the system was raised to 65° C., and the stirring was continued for 3 hours. Then cool the system to room temperature, and finally add water and stir evenly to form A component.

[0030] Component B is composed of 20-30 parts of sodium perchlorate, 10-20 parts of potass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com