Anaerobic sewage treatment device and anaerobic sewage treatment process

A sewage treatment device and sewage treatment technology, applied in anaerobic digestion treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Highly demanding problems, to achieve the effect of easy automatic control, less oxygen consumption, and less labor requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

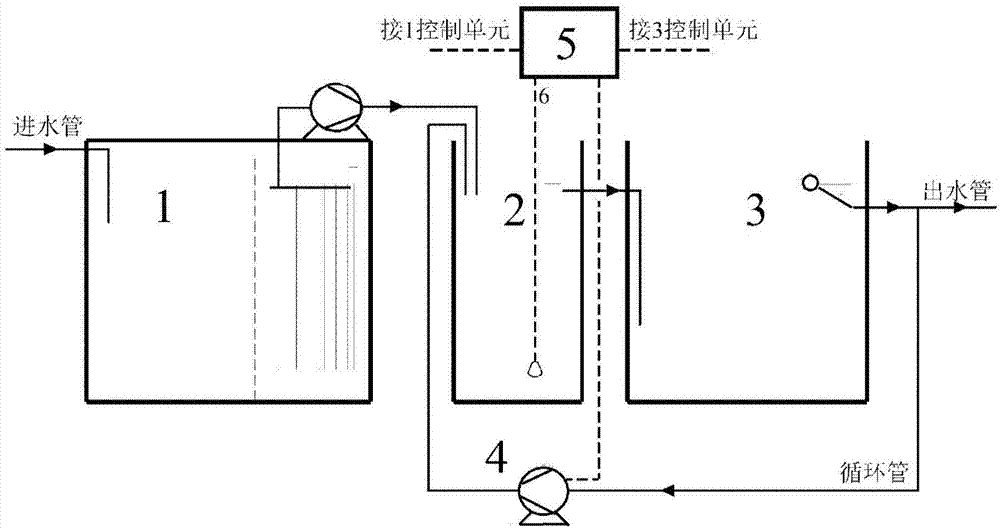

[0056] Oxygen-depleting organic pollutants (COD Cr ) and the total amount of ammonia nitrogen discharge account for the second largest industrial wastewater in my country. For example, agricultural and sideline food processing wastewater, its typical potato starch wastewater COD Cr The concentration is 26300±7800mg / L and the total nitrogen concentration is 1300±200mg / L. The specific process is as follows:

[0057] According to the organic load (2.5-33kgCODCr / kg m3*d) and residence time (0.5-7d) of anaerobic membrane bioreactor 1, and the denitrification load of anammox reactor 3 (0.01-0.3kgTN / kgm3* d) Inoculate the anaerobic digestion sludge and the anammox sludge into the anaerobic membrane bioreactor 1 and the anammox reactor 3 respectively, and then gradually increase the dosage of sewage.

[0058] After inoculation, the potato starch wastewater pumped in from the water inlet first passes through anaerobic membrane bioreactor 1, which receives COD Cr For potato starch wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com