A kind of halogen-free flame retardant and polymer material using the halogen-free flame retardant

A technology of flame-retardant polymers and polymer materials, applied in the field of halogen-free flame retardants and polymer materials using the halogen-free flame retardants, can solve the problems of low thermal stability, narrow application range, and reduced processing and physical Performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

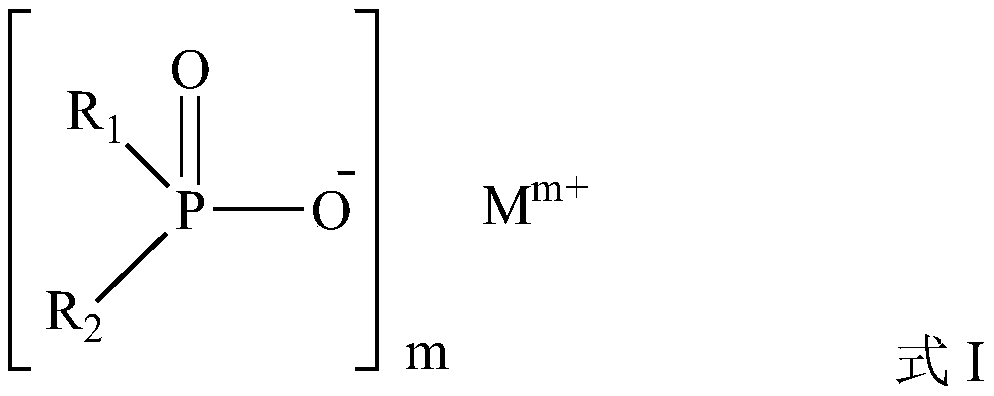

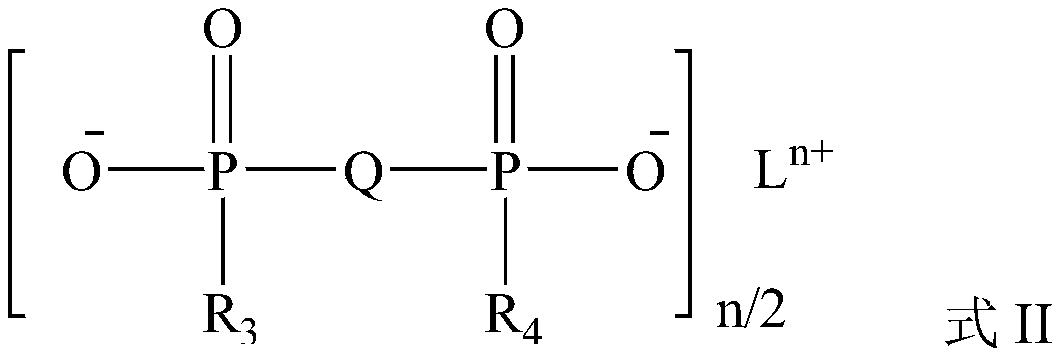

Method used

Image

Examples

Embodiment 1

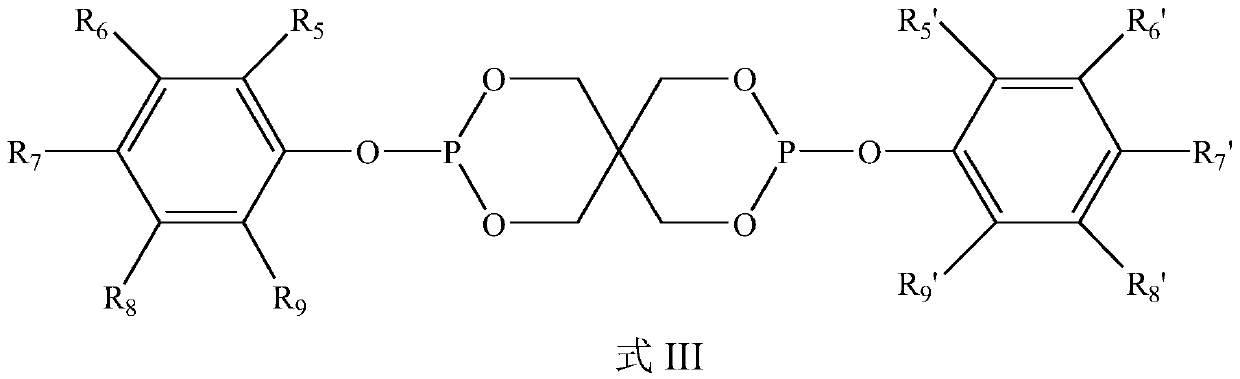

[0085] The synthesis of two (2,4-di-tert-butylphenyl) pentaerythritol diphosphates of embodiment 1

[0086] Dissolve 60g (0.099mol) of bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite in 550g of toluene, stir at room temperature until completely dissolved, then cool down to 10°C, and add 67.5g of it dropwise within 30min (0.595mol) hydrogen peroxide (30% mass fraction), the system was raised to room temperature after dripping, and the reaction was continued for 7.5h. Rotary evaporation, washing with 100 g of isopropanol and 40 g of acetone, suction filtration, washing with water, and drying to obtain 54 g of bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphate, with a yield of 86%.

[0087] 31 P-NMR (85%H 3 PO 4 = 0 ppm): -13.5 ppm.

Embodiment 2

[0089] Mix polyester PBT, antioxidant 626, DePAl-1 and compound antioxidant in a weight ratio of 83.6:1:15:0.4 in an internal mixer with a rotation speed of 50 rpm, and set the temperature at 260°C After 5 minutes, take it out to cool and dry. Then fill it into a mold, preheat it in a flat vulcanizing machine at 260°C for 10 minutes, hold the pressure at 10MPa for 5 minutes, and then cold press it. Cut samples and test after cooling down. The flame retardancy level of the 1.6mm sample is UL94 V-0.

Embodiment 3

[0091] Mix polyester PBT, antioxidant 626, DePAl-1 and compound antioxidant in a weight ratio of 83.6:2:14:0.4 in an internal mixer with a rotation speed of 50 rpm, and set the temperature at 260°C After 5 minutes, take it out to cool and dry. Then fill it into a mold, preheat it in a flat vulcanizing machine at 260°C for 10 minutes, hold the pressure at 10MPa for 5 minutes, and then cold press it. Cut samples and test after cooling down. The flame retardancy level of the 1.6mm sample is UL94 V-0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com