Heat Treatment Process for Improving Spheroidized Structure of Large Die Flat Steel Forgings

A large-scale, ultra-fine treatment technology, applied in the heat treatment process for improving the spheroidized structure of large-scale die flat steel 1.2344 forgings, 1.2344 die flat steel, heat treatment process for improving the spheroidized structure of large-scale die flat steel forgings , can solve the problems of poor spheroidized structure level, coarse steel structure, harsh use environment, etc., and achieve the effect of improving structure uniformity, increasing carbide level, and improving microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Specifications: 365mm×900mm,

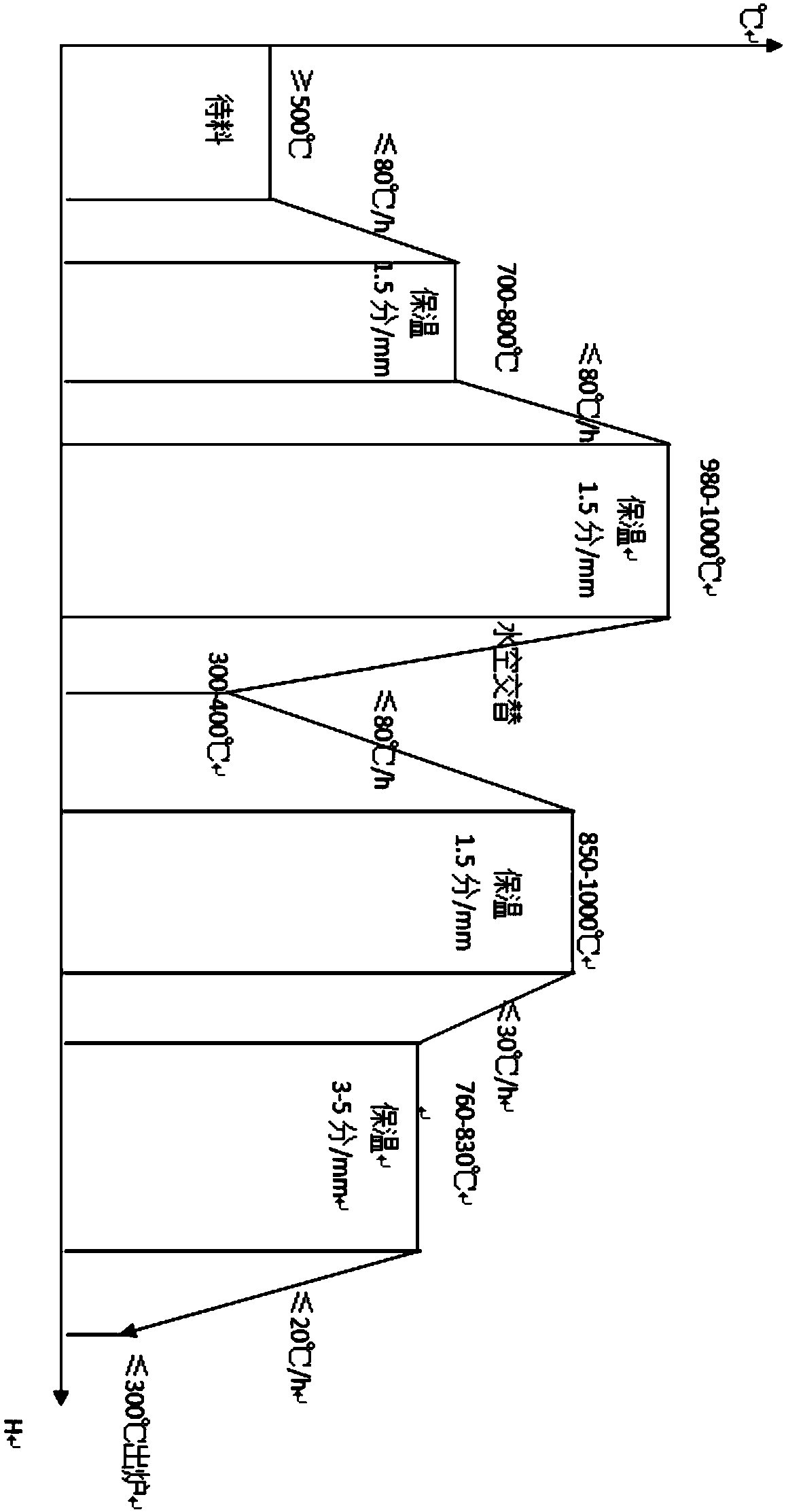

[0032] Such as figure 1 As shown, the processing technology is as follows:

[0033] Step 1: After forging, send the red to the annealing furnace for material: the temperature of the annealing furnace is 512 ° C ~ 560 ° C;

[0034] Step 2: Superfine treatment: preheating temperature is 750°C during normalizing heating, heating rate is 69°C / h, holding time is 1.5min / mm, normalizing temperature is 980°C, holding time is 1.5min / mm; water is used for normalizing cooling Alternating space technology improves the cooling strength, refines the coarse grains produced by high-temperature forging, eliminates the network carbide structure, and controls the material temperature at 320°C to 351°C;

[0035] Step 3: After normalizing, adopt the isothermal spheroidizing annealing process. The isothermal spheroidizing annealing holding temperature is 890°C, the heating rate is 70°C / h, and the holding time is 1.5min / mm, and then the temperature is reduced...

Embodiment 2

[0037] Specifications: 420mm×900mm,

[0038] Such as figure 1 As shown, the processing technology is as follows:

[0039] Step 1: After forging, send the red to the annealing furnace for material: the temperature of the annealing furnace for material is 520 ° C ~ 561 ° C;

[0040] Step 2: Superfine treatment: Preheating temperature is 750°C during normalizing heating, heating rate is 70°C / h, holding time is 1.5min / mm, normalizing temperature is 980°C, holding time is 1.5min / mm; water is used for normalizing cooling Alternating space technology improves the cooling strength, refines the coarse grains produced by high-temperature forging, eliminates the network carbide structure, and controls the material temperature at 320°C to 350°C;

[0041] Step 3: After normalizing, use isothermal spheroidizing annealing treatment process. The isothermal spheroidizing annealing temperature is 890°C, the heating rate is 68°C / h, the holding time is 1.5min / mm, and then the temperature is re...

Embodiment 3

[0043] Specifications: 360mm×910mm,

[0044] Such as figure 1 As shown, the processing technology is as follows:

[0045] Step 1: After forging, send the red to the annealing furnace for material: the temperature of the annealing furnace for material is 515 ° C ~ 555 ° C;

[0046] Step 2: Superfine treatment: preheating temperature is 750°C during normalizing heating, heating rate is 75°C / h, holding time is 1.5min / mm, normalizing temperature is 980°C, holding time is 1.5min / mm; water is used for normalizing cooling Alternating space technology improves the cooling strength, refines the coarse grains produced by high-temperature forging, eliminates the network carbide structure, and controls the material temperature at 310°C to 342°C;

[0047] Step 3: After normalizing, adopt the isothermal spheroidizing annealing process. The isothermal spheroidizing annealing holding temperature is 890°C, the heating rate is 70°C / h, and the holding time is 1.5min / mm, and then the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com