A horizontal degreasing device for rare earth feed liquid

A technology of rare earth material liquid and feeding device, which can be applied in the direction of improving process efficiency and can solve the problem of occupying a large space and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

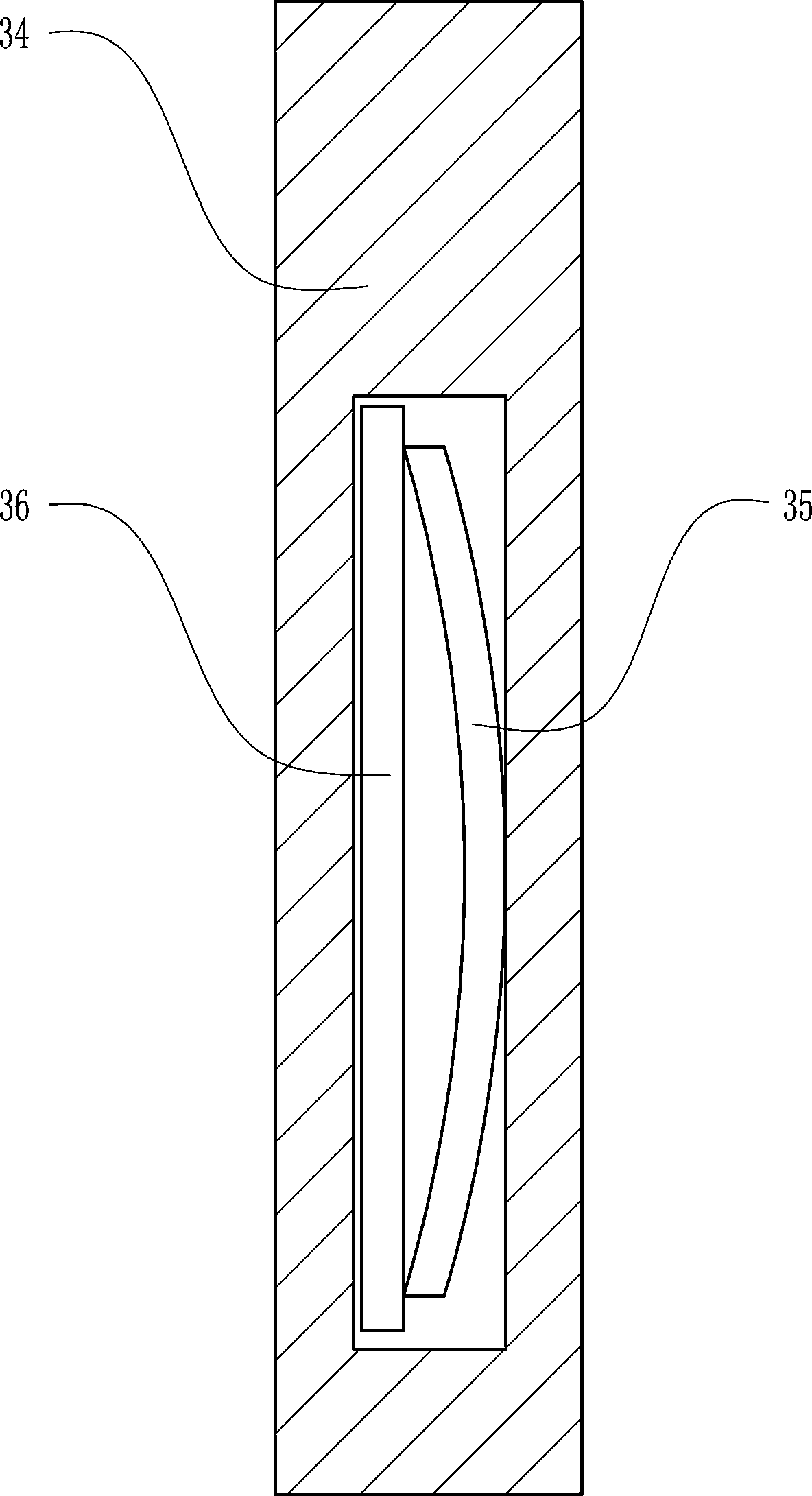

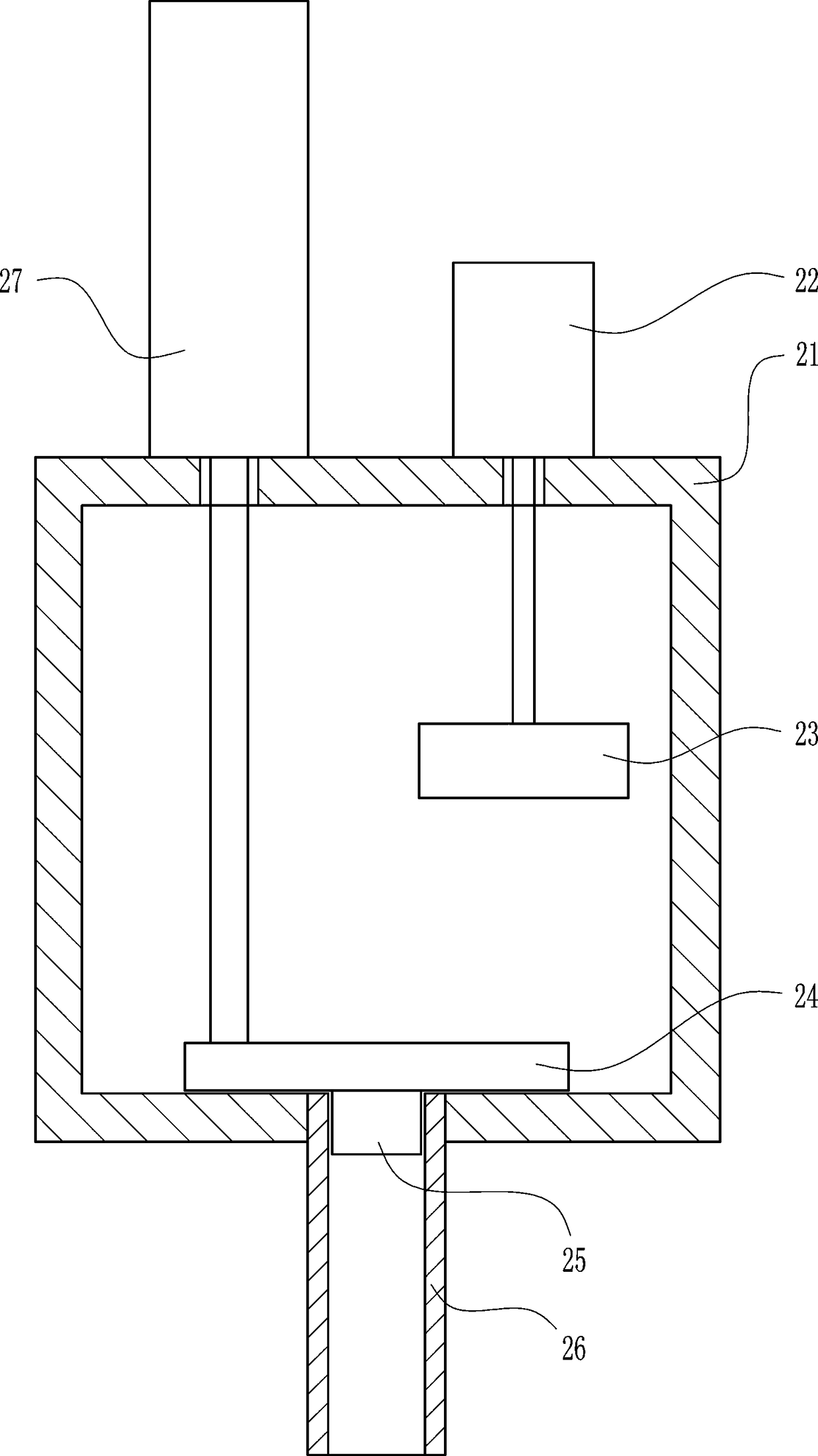

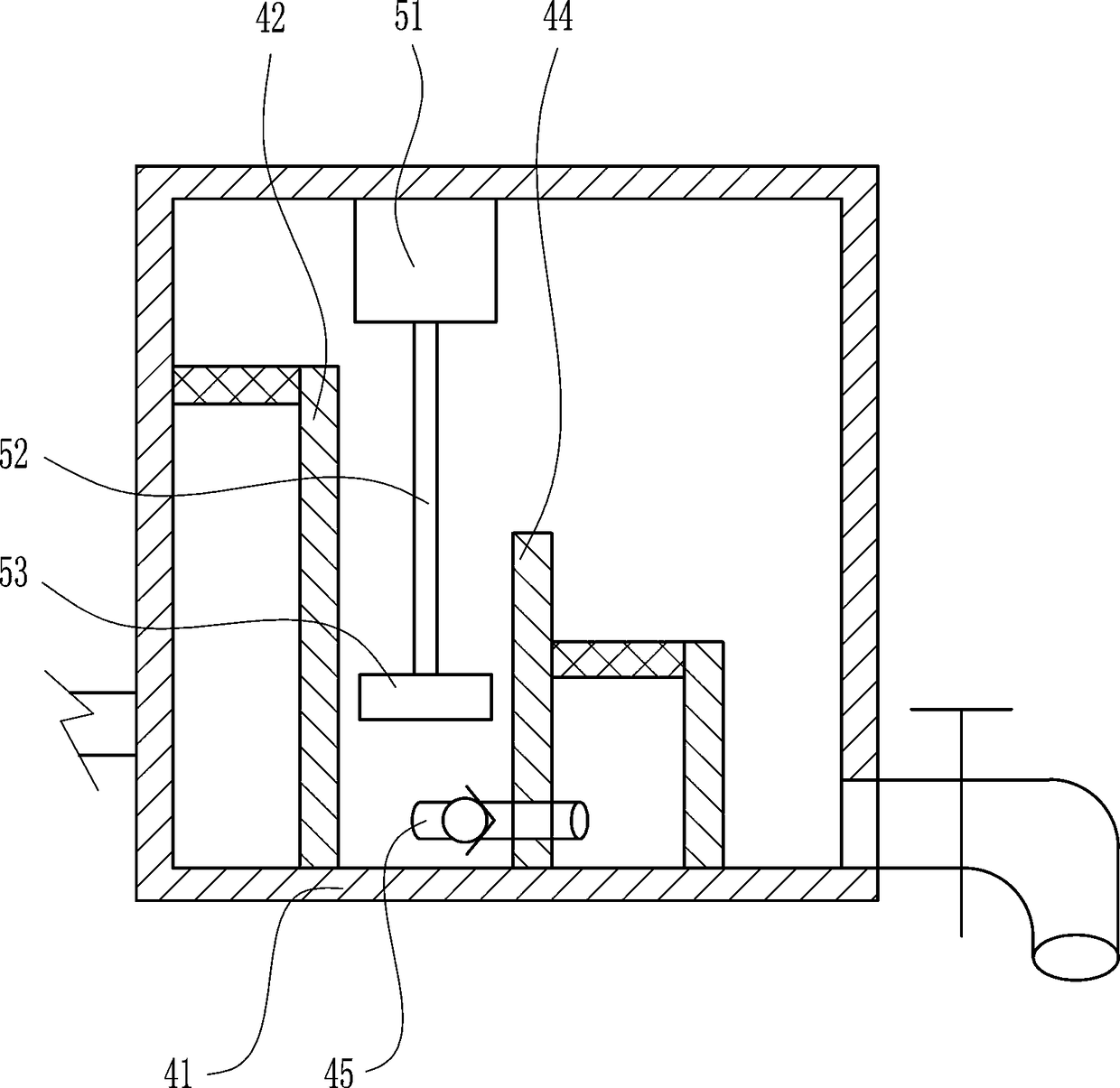

[0031] A horizontal degreasing device for rare earth feed liquid, such as Figure 1-7 As shown, it includes filter cartridge 1, feeding device 2, oil suction device 3, L-shaped connecting plate 4, piston 5, long-stroke cylinder I6, bracket I7, bracket II8, discharge liquid pipe 9 and check valve I10; A feeding device 2 and an oil suction device 3 are arranged above the cylinder 1, the oil suction device 3 is arranged on the right side of the feeding device 2, the L-shaped connecting plate 4 is arranged on the left side of the feeding device 2, the lower end of the L-shaped connecting plate 4 is connected with the filter cartridge The top of 1 is connected by welding, the piston 5 is set in the filter cartridge 1, the piston 5 is matched with the filter cartridge 1, the piston 5 and the filter cartridge 1 are set to be flexibly connected, and the long-stroke cylinder I6 is set on the left side of the filter cartridge 1 , the left side wall of the filter cartridge 1 has a hole, ...

Embodiment 2

[0033] A horizontal degreasing device for rare earth feed liquid, such as Figure 1-7 As shown, it includes filter cartridge 1, feeding device 2, oil suction device 3, L-shaped connecting plate 4, piston 5, long-stroke cylinder I6, bracket I7, bracket II8, discharge liquid pipe 9 and check valve I10; A feeding device 2 and an oil suction device 3 are arranged above the cylinder 1, the oil suction device 3 is arranged on the right side of the feeding device 2, the L-shaped connecting plate 4 is arranged on the left side of the feeding device 2, the lower end of the L-shaped connecting plate 4 is connected with the filter cartridge The top of 1 is connected by welding, the piston 5 is set in the filter cartridge 1, the piston 5 is matched with the filter cartridge 1, the piston 5 and the filter cartridge 1 are set to be flexibly connected, and the long-stroke cylinder I6 is set on the left side of the filter cartridge 1 , the left side wall of the filter cartridge 1 has a hole, ...

Embodiment 3

[0036] A horizontal degreasing device for rare earth feed liquid, such as Figure 1-7 As shown, it includes filter cartridge 1, feeding device 2, oil suction device 3, L-shaped connecting plate 4, piston 5, long-stroke cylinder I6, bracket I7, bracket II8, discharge liquid pipe 9 and check valve I10; A feeding device 2 and an oil suction device 3 are arranged above the cylinder 1, the oil suction device 3 is arranged on the right side of the feeding device 2, the L-shaped connecting plate 4 is arranged on the left side of the feeding device 2, the lower end of the L-shaped connecting plate 4 is connected with the filter cartridge The top of 1 is connected by welding, the piston 5 is set in the filter cartridge 1, the piston 5 is matched with the filter cartridge 1, the piston 5 and the filter cartridge 1 are set to be flexibly connected, and the long-stroke cylinder I6 is set on the left side of the filter cartridge 1 , the left side wall of the filter cartridge 1 has a hole, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com