A kind of high-temperature preparation method of w-si-c system reactant

A reactant, w-si-c technology, applied in the field of high-temperature preparation of W-Si-C reactant, can solve the problem of low reaction efficiency, achieve high preparation efficiency, clean phase interface, and good phase interface compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

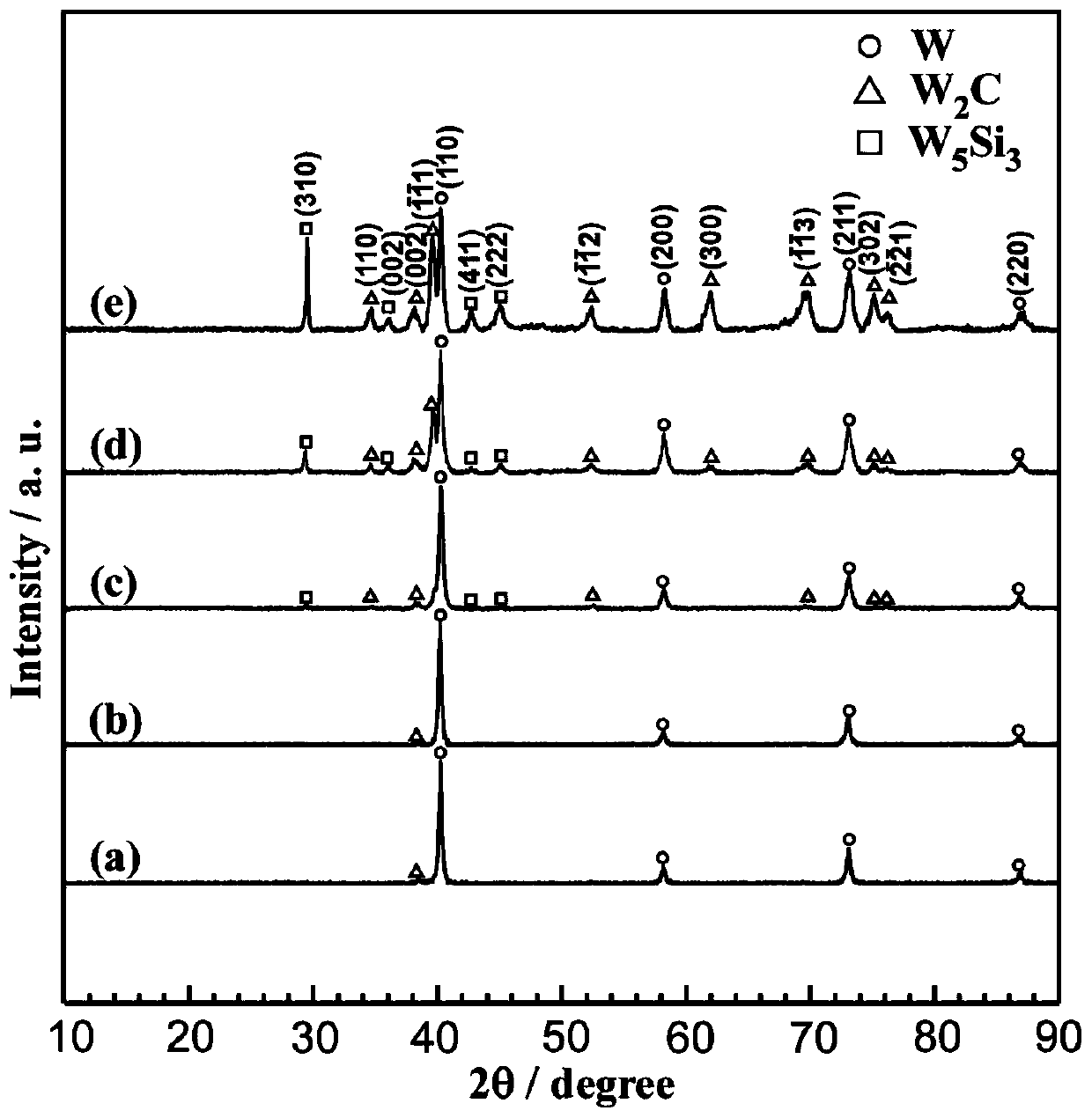

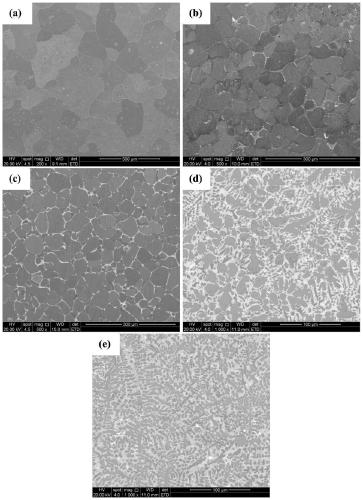

Embodiment 1

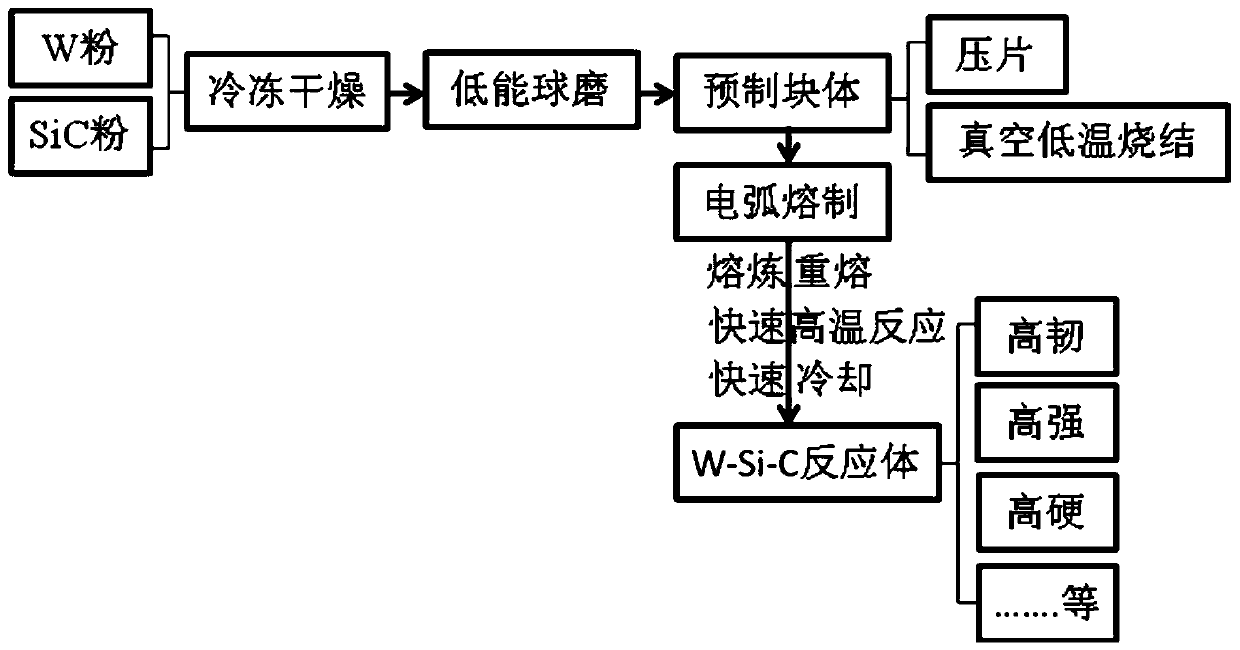

[0028] Preparation of high toughness W-Si-C system reactant. The preparation process is successively through powder weighing, drying treatment and powder mixing, prefabricated block preparation and arc melting. The W-Si-C-based reactant body was obtained after rapid cooling. The specific steps are as follows:

[0029] 1. Weighing, drying and mixing:

[0030] Weigh 9.9g of W powder and 0.1g of SiC powder with a purity of 99% and a particle size of 500nm (the mass ratio of W and SiC is 99:1), freeze-dry the mixed powder for 24 hours using a freeze-drying equipment, and then use a low-energy ball mill to mill Mix evenly for 6 hours to obtain mixed powder.

[0031] 2. Preparation of prefabricated blocks:

[0032] The mixed powder obtained in step 1 is packed into a 304L mould, and a tablet press is used to carry out cold press molding (pressure 30MPa), and the molding time is 3min to obtain a block green body; degree is 10 -3 The Pa pressure is 30MPa, and the temperature is ...

Embodiment 2

[0036] Preparation of high compressive strength W-Si-C system reactant. The preparation process is successively through powder weighing, drying treatment and powder mixing, prefabricated block preparation and arc melting. The W-Si-C-based reactant body was obtained after rapid cooling. The specific steps are as follows:

[0037] 1. Weighing, drying and mixing:

[0038] Weigh 9.6g of W powder with a particle size of 1 μm and 0.4 g of SiC powder with a particle size of 1 μm (the mass ratio of W and SiC is 96:4) with a purity of 99%, and freeze-dry the mixed powder for 24 hours using a freeze-drying equipment. Finally, use a low-energy ball mill for 12 hours to mix evenly.

[0039] 2. Preparation of prefabricated blocks:

[0040] The mixed powder obtained in step 1 is packed into a 304L mould, and a tablet press is used to carry out cold press molding (pressure 50MPa), and the molding time is 5min to obtain a block green compact; -3 Pa pressure is 100MPa, 1000°C heat preserv...

Embodiment 3

[0044] Preparation of high hardness W-Si-C system reactant. The preparation process is successively through powder weighing, drying treatment and powder mixing, prefabricated block preparation and arc melting. The W-Si-C-based reactant body was obtained after rapid cooling. The specific steps are as follows:

[0045] 1. Weighing, drying and mixing:

[0046] Weigh 9.6g of W powder with a particle size of 500nm and 0.4g of SiC powder with a particle size of 40nm (the mass ratio of W and SiC is 96:4) with a purity of 99% and freeze-dry the mixed powder for 24 hours, and then Use a low-energy ball mill for 12 hours to mix evenly.

[0047] 2. Preparation of prefabricated blocks:

[0048] The mixed powder obtained in step 1 is packed into a 304L mould, and a tablet press is used to carry out cold press molding (pressure 50MPa), and the molding time is 3min to obtain a block green body; after that, through discharge plasma sintering (vacuum degree is 10 -3 The Pa pressure is 30M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com