A kind of amorphous modifier for low-alloy cast steel and its preparation method and application

A low-alloy cast steel, amorphous technology, applied in the field of metal materials and metallurgy, can solve the problems of molten steel pollution, large size differences, waste of elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

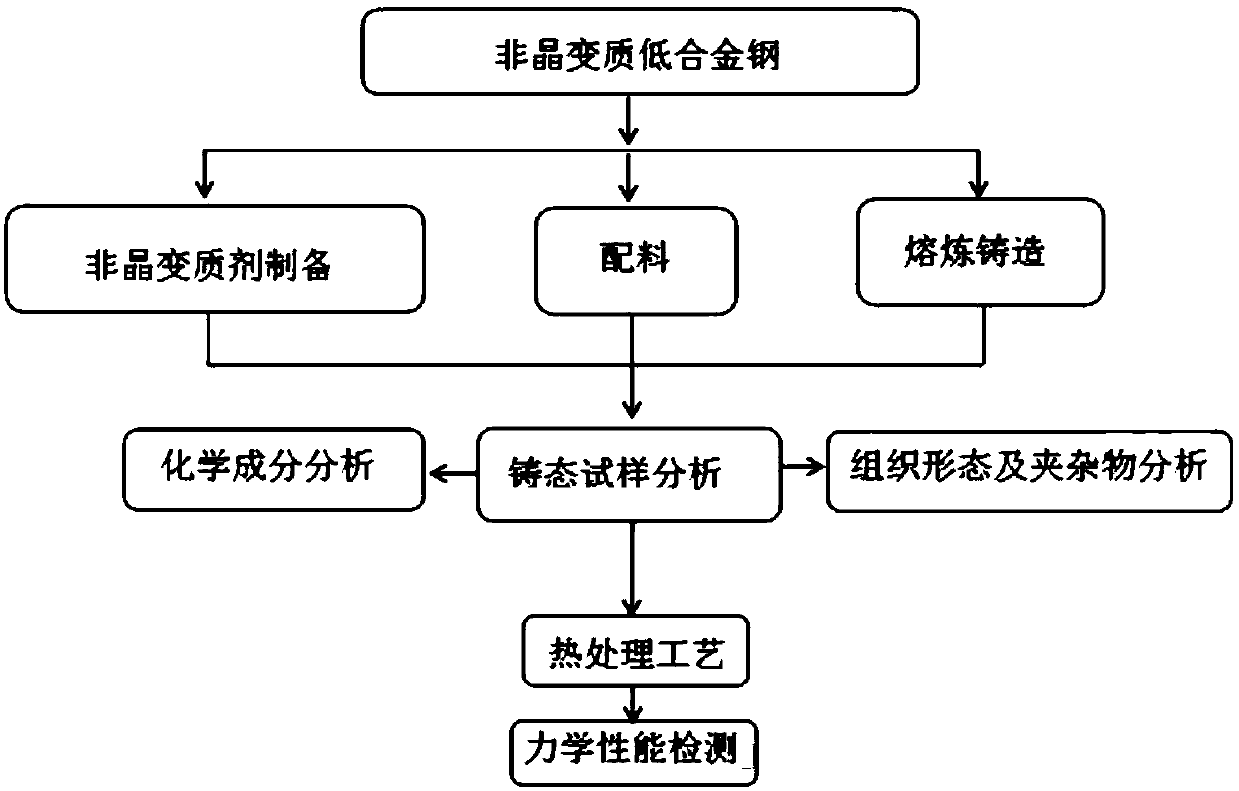

Method used

Image

Examples

Embodiment 1

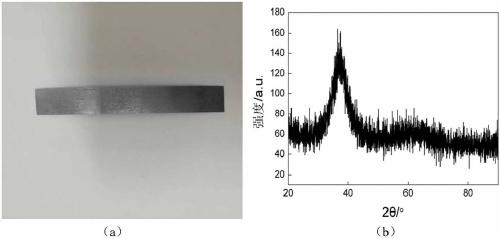

[0031] Step 1: Polish the surface oxide layers of metal materials such as Ce, Al, Ni, Nb and Cu with a purity of not less than 99.9%, and then clean them according to Ce 22.63g, Al 0.76g, Ni 2.08g, Cu 1.89g , Nb2.63g (the corresponding atomic ratio is calculated as: Ce 58%Al 10%Ni 12.5%Cu 10.5%Nb 9%) composition ratio Put the prepared materials evenly into the electric arc furnace crucible, and then cover the furnace Cover, evacuated to 5.0 x 10 -3 Pa and then fill the furnace with high-purity Ar gas with a purity of 99.9% to dilute the residual gas in the furnace cavity, and then evacuate to 5.0×10 -3 Pa, and then fill the furnace with 0.6 atmospheric pressure of high-purity Ar gas. First smelt pure titanium for 3.5 minutes, and then smelt pure titanium placed in another crucible next to the alloy for 3.5 minutes to consume oxygen in the furnace cavity and ensure the purity of the master alloy smelting. Then smelt the alloy, smelting 100s-110s at a constant power of 20KW, t...

Embodiment 2

[0035] The first step: polish the surface oxide layer of metal materials such as Ce, Al, Ni, Nb and Cu with a purity of not less than 99.9%, and then clean the surface according to Ce 33.19g, Al1.12g, Ni 3.05g, Cu 2.77g Nb 3.86g (calculated corresponding atomic ratio: Ce 57%Al 10%Ni 12.5%Cu 10.5%Nb 10%) composition ratio Place the prepared materials evenly in the electric arc furnace crucible, and then cover the furnace cover , vacuumed to 6.0×10 -3 After Pa, fill the furnace with high-purity Ar gas with a purity of 99.9% to dilute the residual gas in the furnace cavity, and then evacuate to 6.0×10 -3 Pa, and then fill the furnace with 0.7 atmospheric pressure of high-purity Ar gas. First smelt pure titanium for 3.5 minutes to consume free oxygen in the vacuum furnace. Then the alloy is smelted to ensure smelting for 100s-110s at a constant power of 20KW. In order to make the composition of the alloy uniform, use an electromagnetic stirring handle to stir, and turn the allo...

Embodiment 3

[0039] The first step: Polish the surface oxide layer of metal materials such as Ce, Al, Ni, Nb and Cu with a purity of not less than 99.9%, and then clean the surface according to Ce47.15g, Al1.59g, Ni4.33g, Cu3.94g, Nb5.49g (the calculated corresponding atomic ratio is: Ce56%Al 10%Ni 12.5%Cu 10.5%Nb 11%) composition ratio Place the prepared materials evenly in the electric arc furnace crucible, and then cover the furnace cover, Vacuum to 7.0×10 -3 Pa and then fill the furnace with high-purity Ar gas with a purity of 99.9% to dilute the residual gas in the furnace cavity, and then evacuate to 7.0×10 -3 Pa, and then fill the furnace with 0.8 atmospheric pressure of high-purity Ar gas. First smelt pure titanium for 3.5 minutes to consume free oxygen in the vacuum furnace. Then smelt the alloy, and ensure that it is smelted at a constant power of 20KW for 100s-110s. In order to make the alloy composition uniform, use an electromagnetic stirring handle to stir, turn the alloy i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com