A kind of whole grain instant black rice flour processing method that reduces the loss of active substance

A technology of active substances and processing methods, applied in the field of whole grain instant black rice flour processing, can solve the problems of loss of nutrients, degradation and destruction, reduction of antioxidant activity, etc., and achieves improvement of antioxidant capacity, reduction of water absorption index, sensory score improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

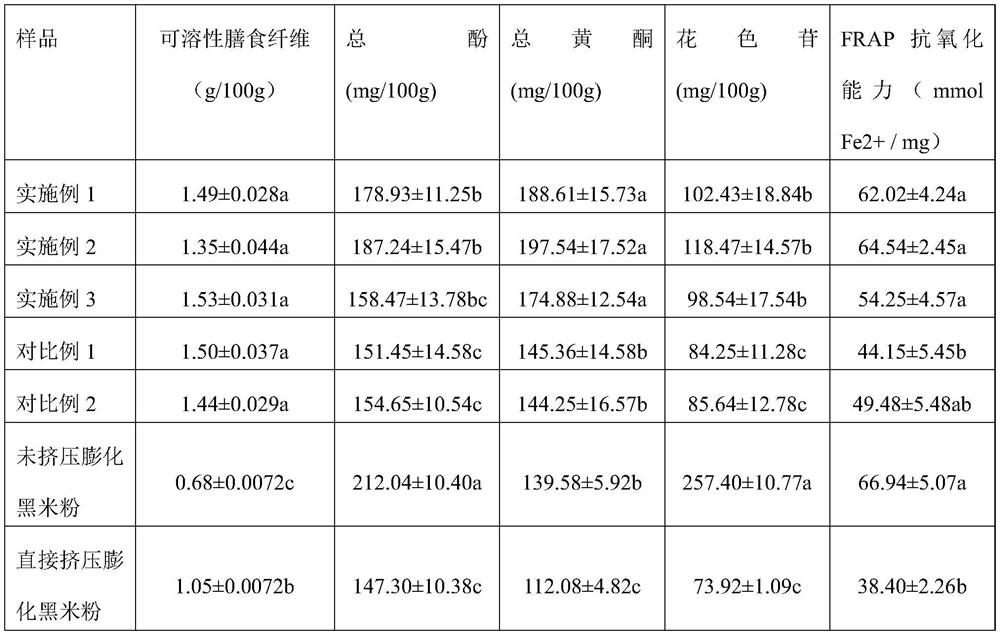

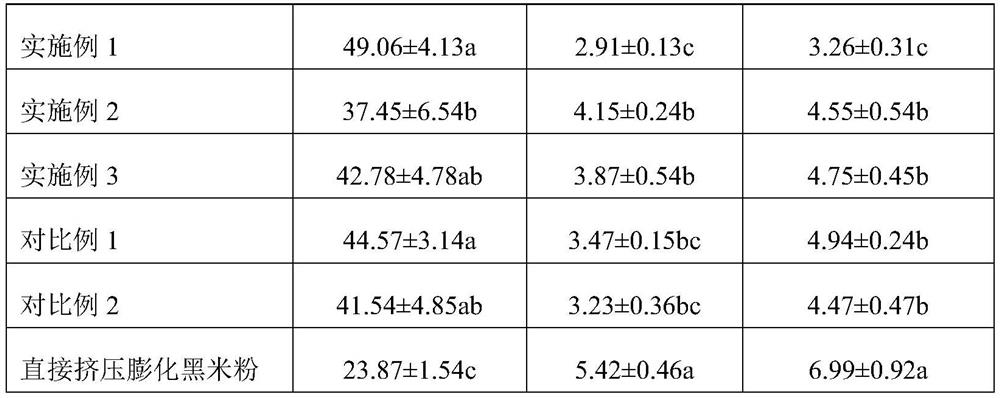

Embodiment 1

[0026] The invention discloses a method for processing whole grain instant black rice flour which reduces the loss of active substances, specifically: fresh black rice is crushed and passed through a 40-mesh sieve. Citric acid, calcium carbonate, vitamin C and glucose are mixed in a mass ratio of 0.25:0.1:0.25:0.25 and then added to the crushed black rice. The total amount of compound exogenous additives added to the black rice flour is 4%. . Adjust the moisture content to 10% after mixing well. The conditions for extrusion expansion are as follows: the temperature of zone I of the screw extruder is 20°C, the temperature of zone II is 120°C, the temperature of zone III is 150°C, and the rotational speed of the screw is 170r / min. The black rice sample obtained after extrusion and puffing was pulverized and passed through a 40-mesh sieve to obtain high-quality instant whole grain black rice flour.

Embodiment 2

[0028] The invention discloses a method for processing whole grain instant black rice flour which reduces the loss of active substances, specifically: fresh black rice is crushed and passed through a 60-mesh sieve. Citric acid, calcium carbonate, vitamin C and glucose are mixed in a mass ratio of 1.5:0.5:1:1.5 and then added to the crushed black rice. The total amount of compound exogenous additives added to the black rice flour is 2.25%. . Adjust the moisture content to 15% after mixing well. The conditions for extrusion expansion are as follows: the temperature of zone I of the screw extruder is 30°C, the temperature of zone II is 130°C, the temperature of zone III is 160°C, and the rotational speed of the screw is 220r / min. The black rice sample obtained after extrusion and puffing was pulverized and passed through a 60-mesh sieve to obtain high-quality instant whole grain black rice flour.

Embodiment 3

[0030] The invention discloses a method for processing whole grain instant black rice flour which reduces the loss of active substances, specifically: fresh black rice is crushed and passed through an 80-mesh sieve. Citric acid, calcium carbonate, vitamin C and glucose are mixed in a mass ratio of 2:1:2:2 and then added to the crushed black rice. The total amount of compound exogenous additives added to the black rice flour is 0.85%. . Adjust the moisture content to 20% after mixing evenly. The conditions for extrusion expansion are as follows: the temperature of zone I of the screw extruder is 40°C, the temperature of zone II is 140°C, the temperature of zone III is 170°C, and the rotational speed of the screw is 220r / min. The black rice sample obtained after extrusion and puffing was pulverized and passed through an 80-mesh sieve to obtain high-quality instant whole grain black rice flour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com