Magnesium alloy helmet adopting honeycomb reinforcing ribs

A magnesium alloy and helmet technology, applied in the field of magnesium alloy helmets, can solve the problems of decreased helmet strength and human cervical vertebra compression, and achieves the effects of protecting the human body, reducing injuries, and having good impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention has no special limitation on the preparation method of the helmet skeleton, and can be directly prepared by adopting the magnesium alloy forming technical scheme well known to those skilled in the art, such as by adopting the method of integral die casting.

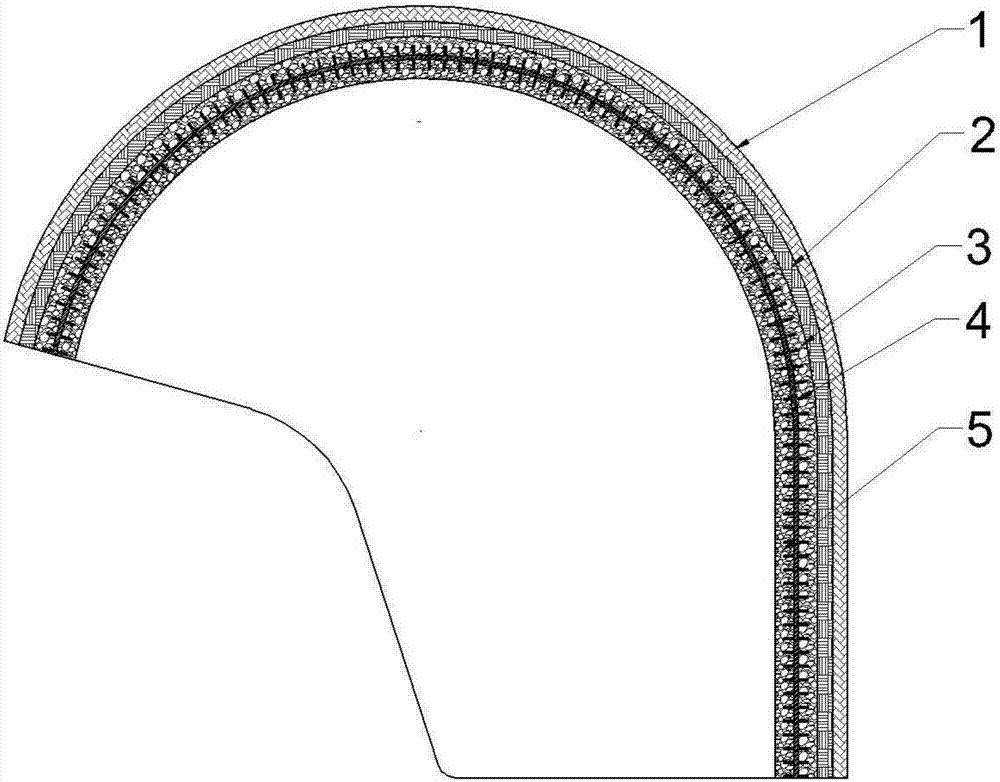

[0055] In the present invention, the aerogel filled in the inner honeycomb structure of the helmet frame is referred to as the inner aerogel layer, and the aerogel filled in the outer honeycomb structure of the helmet frame is referred to as the outer aerogel layer. In the present invention, aerogel is a form of solid matter, which is one of the solids with low density in the world. The density is 3 kilograms per cubic meter, which is only 2.75 times the density of air. Since more than 80% of the aerogel is air, it has a very good thermal insulation effect. One inch thick aerogel is equivalent to the thermal insulation function of 20 to 30 pieces of ordinary glass. Even if the aerogel was pla...

Embodiment 1

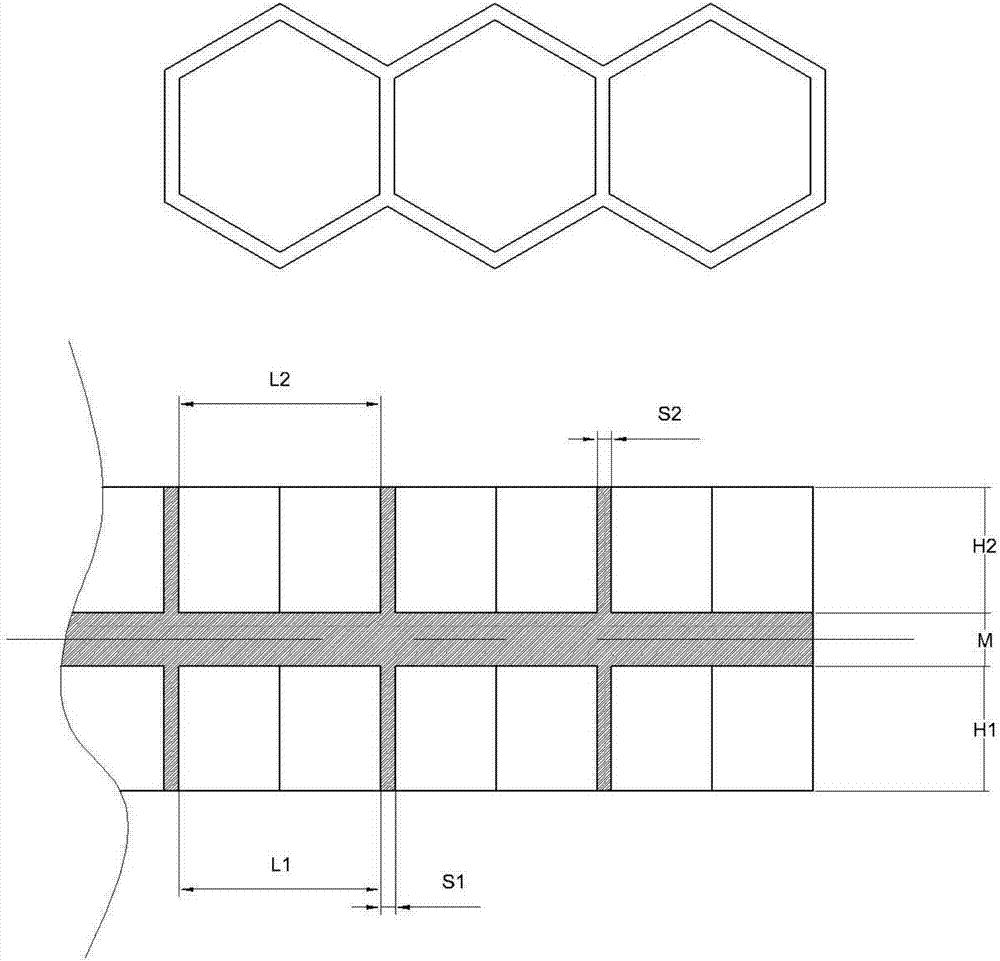

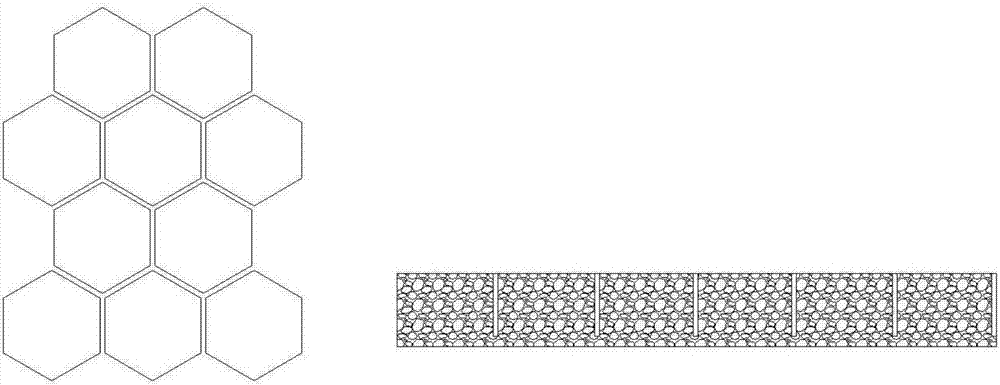

[0079] The AZ91 magnesium alloy helmet skeleton is prepared as a whole by die casting. The helmet skeleton structure is as follows figure 1 As shown, the thickness of the helmet shell is 4mm, the honeycomb structure of the inner and outer surfaces of the helmet shell, the honeycomb structure is formed by several regular hexagonal cells, and the wall thickness of the regular hexagonal cells of the inner surface honeycomb structure is 1mm (S1), The wall height is 10mm (H1), and the diagonal distance is 10mm (L1). L2).

[0080] Cut the aerogel (silica nano-aerogel produced by Jinna Company) into an aerogel liner with regular hexagonal prisms, the size of the regular hexagonal prisms and the size of the regular hexagonal cells in the honeycomb structure are interference fit, The regular hexagonal prism can just be filled into the regular hexagonal cell, and the thickness of the aerogel pad is 10 mm. Filling the prepared two aerogel liners into the honeycomb structure on the inne...

Embodiment 2

[0087] The helmet body was prepared according to the method described in Example 1.

[0088] Use epoxy resin colloid to bond two layers of glass fiber cloth on the outer surface of the helmet helmet, put the helmet body into the mold, heat and pressurize after the mold is closed, the pressurization pressure is 2MPa, the heating temperature is 150℃, and the pressurized heating The time is 4 hours; a fiber cloth layer is formed on the outer surface of the helmet.

[0089] The surface of the fiber cloth layer is coated with a heat-resistant layer slurry to form a heat-resistant layer with a thickness of 1 mm to obtain a fire helmet; Boron ceramic powder, rare earth luminescent powder and aerogel particles.

[0090] After measurement, the weight of the fire helmet prepared in Example 2 of the present invention is 597 grams.

[0091] According to GA 44-93 "National Standard for Fire Helmets", the penetration performance, electrical conductivity and heat resistance performance of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap