Method for preparing reduced graphene oxide/nano ferrosoferric oxide composite magnetic adsorbent

A technology of triiron tetroxide and composite magnetism, applied in the directions of alkali metal oxides/hydroxides, chemical instruments and methods, alkali metal compounds, etc., can solve the problem of low reduction efficiency of graphene oxide, unstable composite structure, influence Magnetic responsiveness and other issues, to achieve the effect of improving the reduction effect, good magnetic responsiveness, and improving magnetic responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

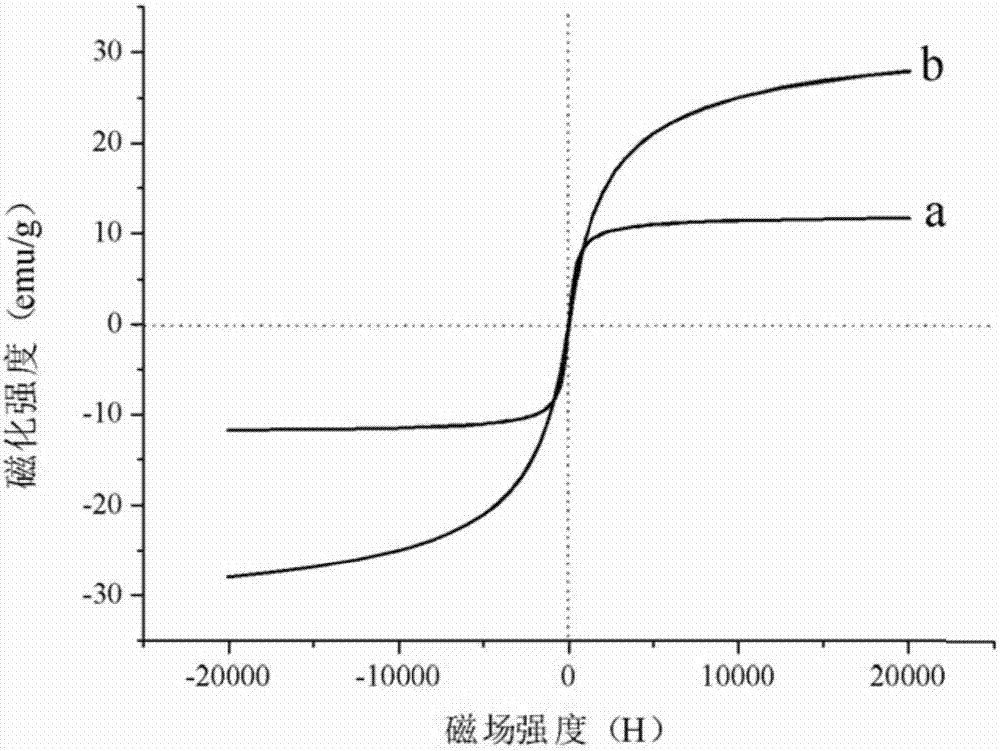

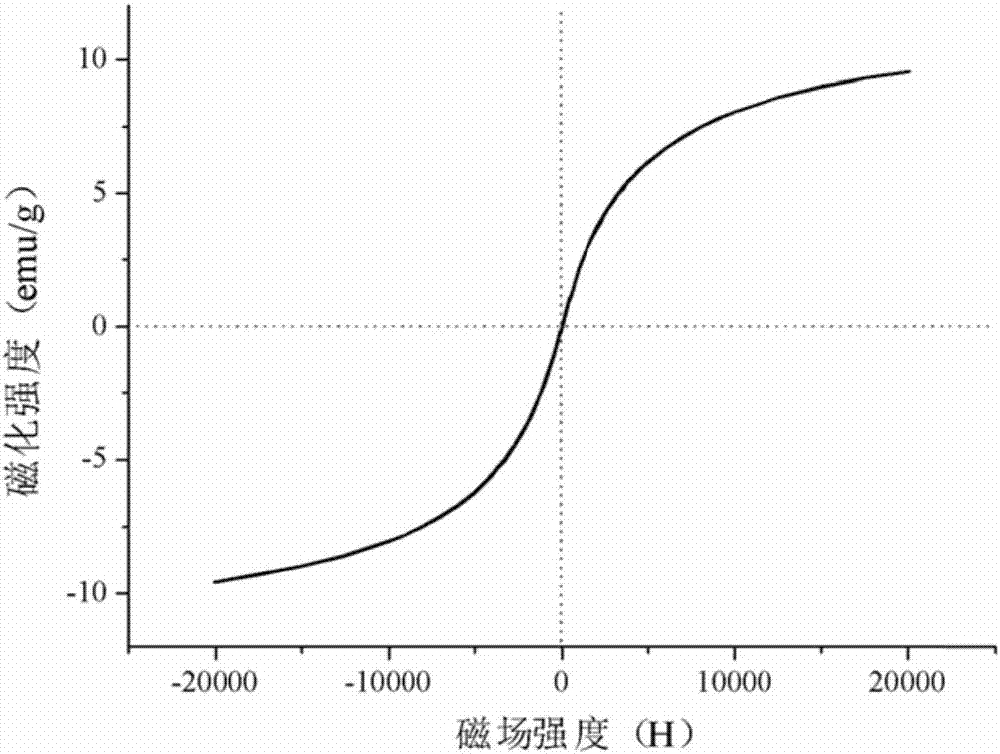

[0030] Prepare water / glycol binary solvent ( 25 mL ethylene glycol and 5 mL water) , add 97.5 mg GO, 195 mg ferric chloride hexahydrate (twice the mass of GO), 78 mg sodium citrate, and 597 mg sodium acetate in sequence, stir and mix thoroughly, ultrasonically disperse for 30 minutes, and transfer to the reaction kettle; The reaction kettle was placed in a muffle furnace, the reaction temperature was 180 °C, and the reaction time was 8 hours; after the reaction, the product was fully washed with ultrapure water and ethanol, and vacuum-dried after magnetic separation to obtain rGO / Fe 3 o 4 .

[0031] Carry out VSM test to the prepared product, the result is as follows figure 2 shown. According to the VSM results, rGO / Fe 3 o 4 The saturation magnetic intensity is 9.5 emu / g. The actual magnetic separation experiment results show that rGO / Fe 3 o 4 The time required for complete separation from the aqueous solution was 147 s, and the supernatant was clear after separation. ...

Embodiment 2

[0033] rGO / Fe 3 o 4 The preparation experiment was the same as in Example 1, except that the dosages of ferric chloride hexahydrate, sodium citrate, and sodium acetate changed: 520 mg ferric chloride hexahydrate (5 times the quality of GO), 208 mg sodium citrate, 1592 mg sodium acetate.

[0034] Carry out VSM test to the prepared product, the result is as follows image 3 shown. According to the VSM results, rGO / Fe 3 o 4 The saturation magnetic intensity is 18.9 emu / g. The actual magnetic separation experiment results show that rGO / Fe 3 o 4 The time required for complete separation from the aqueous solution was 70 s, and the supernatant was clear after separation. The above results show that rGO / Fe 3 o 4 The preparation effect is good, rGO / Fe 3 o 4 The structure and performance are stable, and the magnetic response performance is good.

Embodiment 3

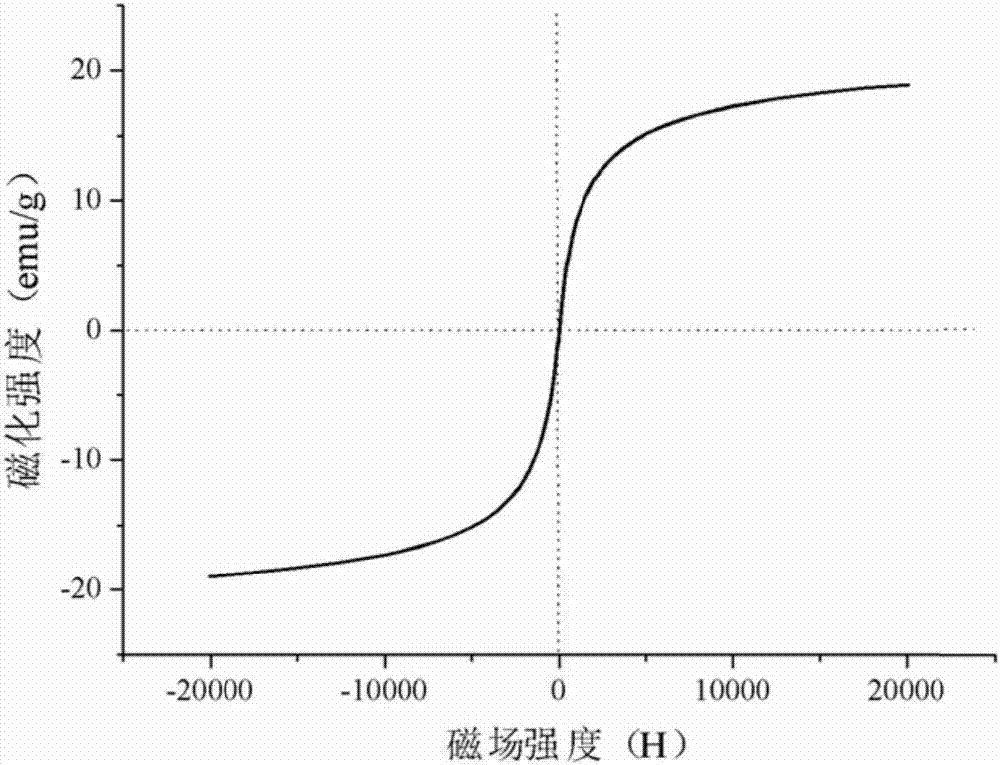

[0036] rGO / Fe 3 o 4 The preparation experiment was the same as in Example 1, except that the dosages of ferric chloride hexahydrate, sodium citrate, and sodium acetate changed: 260 mg ferric chloride hexahydrate (2.5 times the mass of GO), 104 mg sodium citrate, 796 mg sodium acetate.

[0037] Carry out VSM test to the prepared product, the result is as follows Figure 4 shown. According to the VSM results, rGO / Fe 3 o 4 The saturation magnetic intensity is 11.8 emu / g. The actual magnetic separation experiment results show that rGO / Fe 3 o 4 The time required for complete separation from the aqueous solution was 75 s, and the supernatant was clear after separation. The above results show that rGO / Fe 3 o 4 The preparation effect is good, rGO / Fe 3 o 4 The structure and performance are stable, and the magnetic response performance is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic strength | aaaaa | aaaaa |

| Saturation magnetic strength | aaaaa | aaaaa |

| Saturation magnetic strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com