Antifriction polyurethane coating and preparing method thereof

A technology of polyurethane coating and weight ratio, applied in the field of coatings, can solve the problems of reducing the protection effect of the substrate, lack of friction-reducing polyurethane, and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

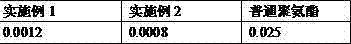

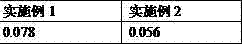

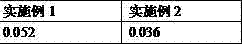

Examples

Embodiment 1

[0025] A friction-reducing polyurethane coating composed of material A and curing agent in a weight ratio of 3:1.

[0026] The material A is composed of the following parts by weight:

[0027] Coconut diethanolamide 2, oleic acid 13, trimethylolpropane 10, polyamide wax powder 3, polycarbonate diol 120, tin butyl mercaptan 1, zinc ricinoleate 2, inorganic lubricating filler 20, Diacetone alcohol 10, hexamethyl cyclotrisiloxane 1, stabilizer 2, 2,2'-dibenzamidodiphenyl disulfide 4, isophorone diisocyanate 105, 2-methoxychloroethyl Alkane 0.5, Dichloroglyoxime 0.3.

[0028] The inorganic lubricating filler is a mixture of silicon micropowder and molybdenum disulfide with a weight ratio of 30:1.

[0029] The stabilizer is zinc stearate.

[0030] The preparation method of material A includes the following steps:

[0031] (1) Take the inorganic lubricating filler, add it to 14 times its weight in absolute ethanol, stir evenly, add trimethylolpropane, 2-methoxychloroethane 0.5, dichloroglyox...

Embodiment 2

[0040] An anti-friction polyurethane coating composed of material A and curing agent in a weight ratio of 2:1.

[0041] The material A is composed of the following parts by weight:

[0042] Coconut diethanolamide 1, oleic acid 10, trimethylolpropane 8, polyamide wax powder 2, polycarbonate diol 110, tin butyl mercaptan 0.3, zinc ricinoleate 1, inorganic lubricating filler 16, Diacetone alcohol 8, hexamethylcyclotrisiloxane 0.4, stabilizer 0.8, 2,2'-dibenzamidodiphenyl disulfide 3, isophorone diisocyanate 100, 2-methoxychloroethyl Alkane 0.5, Dichloroglyoxime 0.3.

[0043] The inorganic lubricating filler is a mixed composition of silicon micropowder and molybdenum disulfide with a weight ratio of 20:0.7.

[0044] The stabilizer is barium stearate.

[0045] The preparation method of material A includes the following steps:

[0046] (1) Take the inorganic lubricating filler, add it to 10 times its weight in absolute ethanol, stir evenly, add trimethylolpropane, 2-methoxychloroethane 0.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com