Preparation method of low-molecular-weight pectin

A low-molecular-weight, pectin-based technology is applied to medical preparations containing active ingredients, pharmaceutical formulas, and organic active ingredients. Oxidative and anticancer activity, enhance the body's immunity, easy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0021] (1) obtain pectin from industrial water, then mix 125mg pectin (Mw==7.9×10 6 ) was dissolved in 25ml of 0.1M sodium acetate buffer solution (pH 6.8), hydrogen peroxide (final concentration 6g / L) and ascorbic acid (final concentration 10mmol / L) were added.

[0022] (2) Place the solution obtained in step 1) at a temperature of 30°C for ultrasonic treatment, the treatment time is 10 minutes, and the ultrasonic sound field intensity is 424W / cm 2 , At this time, the ultrasonic frequency is 21-25kHz (remarks: the instrument adjusts within this range by itself).

[0023] (3) Dialyze the treated solution obtained in step 2) (a dialysis bag with a cut-off of 3500Da), vacuum freeze-dry (at a vacuum degree of 0.1MPa, dry at -45°C for 36h), and the obtained low molecular weight pectin is gelled The molecular weight of the product was detected by gel permeation chromatography, and its molecular weight (kDa) was 19.26 kDa.

Embodiment 1-2~1-4

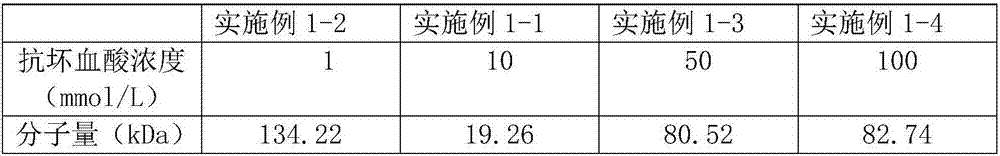

[0025] In order to verify the influence of different ascorbic acid concentrations in step 1) on the prepared low-molecular-weight pectin, change the ascorbic acid concentration in step 2), and the rest are the same as in Example 1-1, thereby obtaining Examples 1-2 to 1-4, specifically The concentration of ascorbic acid and the corresponding molecular weight of the resulting low molecular weight pectin are shown in Table 1.

[0026] Table 1. Molecular weight of low molecular weight pectin obtained with different ascorbic acid concentrations

[0027]

[0028] As can be found from Table 1, when the concentration of ascorbic acid is 1-10mmol / L, after 10 minutes of action, along with the increase of the concentration of ascorbic acid, the molecular weight of the gained pectin significantly decreases, and when the concentration of ascorbic acid is 10-100mmol / L, the degradation trend decreases with The concentration of ascorbic acid decreased and increased, and the molecular weigh...

Embodiment 2-1~2-3

[0030] In order to verify the impact of degradation on the prepared low molecular weight pectin at different reaction temperatures in step 2), change the reaction temperature in step 2) in Example 1-1, and the rest are the same as in Example 1-1, thereby obtaining Example 2 -1~2-3, the specific reaction temperature and the molecular weight of the corresponding obtained low molecular weight pectin are shown in Table 2.

[0031] Table 2. Molecular weight of low molecular weight pectin obtained at different reaction temperatures

[0032] Example 1-1 Example 2-1 Example 2-2 Example 2-3 temperature(℃) 30 20 40 50 Molecular weight (kDa) 19.26 43.45 11.62 9.28

[0033] It can be found from Table 2 that when the reaction temperature is 20-50°C, after ultrasonication for 10 minutes, the molecular weight of the obtained pectin decreases significantly with the increase of the reaction temperature, and is concentrated at 9.28-43.45kDa. When the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com