Direct vanadium extracting method for vanadium-titanium magnetite

A vanadium-titanium-magnetite, direct technology, applied in the field of vanadium chemical metallurgy, can solve the problem of not being able to directly obtain vanadium products, and achieve the effects of low equipment requirements, comprehensive utilization, and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

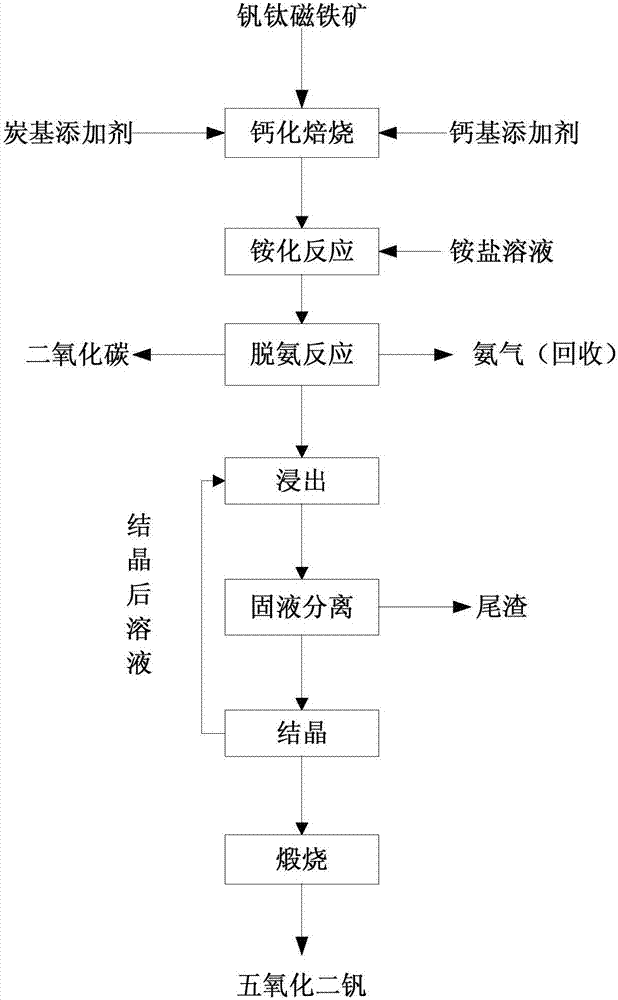

Image

Examples

Embodiment 1

[0064] A method for directly extracting vanadium from vanadium-titanium magnetite, comprising the steps of:

[0065] will V 2 o 5 Content is 1.52wt% vanadium-titanium magnetite, calcium carbonate and activated carbon are mixed, and the addition of calcium carbonate is 1% of vanadium-titanium magnetite weight, and the addition of activated carbon is 1% of vanadium-titanium magnetite weight, in Calcification and roasting at 900°C for 3 hours to obtain roasted clinker;

[0066] Mix the clinker, ammonium bicarbonate and water, the amount of ammonium bicarbonate added is 5% of the clinker mass, the water added is 15% of the clinker mass, the mixed material is ammonized at 20°C for 5 hours, and extracted Vanadium in clinker;

[0067] After the ammonification, the slurry was subjected to a deamination reaction at 80°C for 3 hours. After the ammonium bicarbonate was completely decomposed, the vanadium in the slurry was leached by adding 80°C circulating crystallization liquid, leac...

Embodiment 2

[0070] A method for directly extracting vanadium from vanadium-titanium magnetite, comprising the steps of:

[0071] will V 2 o 5 Content is 1.6wt% vanadium-titanium magnetite, calcium carbonate and active carbon are mixed, and the addition of calcium carbonate is 3% of vanadium-titanium magnetite weight, and the addition of activated carbon is 3% of vanadium-titanium magnetite weight, in Calcification and roasting at 1000°C for 3 hours to obtain roasted clinker;

[0072] Mix the clinker, ammonium bicarbonate and water, the amount of ammonium bicarbonate added is 7% of the clinker mass, the water added is 18% of the clinker mass, the mixed material is ammonized at 30°C for 3 hours, and extracted Vanadium in clinker;

[0073] After the ammonification, the slurry was subjected to a deamination reaction at 90°C for 3 hours. After the ammonium bicarbonate was completely decomposed, the vanadium in the slurry was leached by adding a 90°C circulating crystallization solution for ...

Embodiment 3

[0076] A method for directly extracting vanadium from vanadium-titanium magnetite, comprising the steps of:

[0077] will V 2 o 5 Content is 1.52wt% vanadium-titanium magnetite, calcium carbonate and activated carbon are mixed, and the addition of calcium carbonate is 5% of vanadium-titanium magnetite weight, and the addition of activated carbon is 5% of vanadium-titanium magnetite weight, in Calcification and roasting at 1000°C for 2 hours to obtain roasted clinker;

[0078] Mix the clinker, ammonium bicarbonate and water, the amount of ammonium bicarbonate added is 10% of the clinker mass, the water added is 20% of the clinker mass, the mixed material is ammonized at 45°C for 2 hours, and extracted Vanadium in clinker;

[0079] After the ammonification, the slurry was subjected to a deamination reaction at 100°C for 2 hours. After the ammonium bicarbonate was completely decomposed, the vanadium in the slurry was leached by adding 95°C circulating crystallization liquid fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com