System for applying clean energy to produce hydrogen by electrolysis and injecting hydrogen into gas pipeline network

A technology of clean energy and hydrogen production system, which is applied in wind power generation, energy industry, electrical components, etc., can solve the problems of low efficiency of hydrogen production system and cannot be suitable for large-scale hydrogen energy production, and achieve convenient storage and transportation, The effect of increasing operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

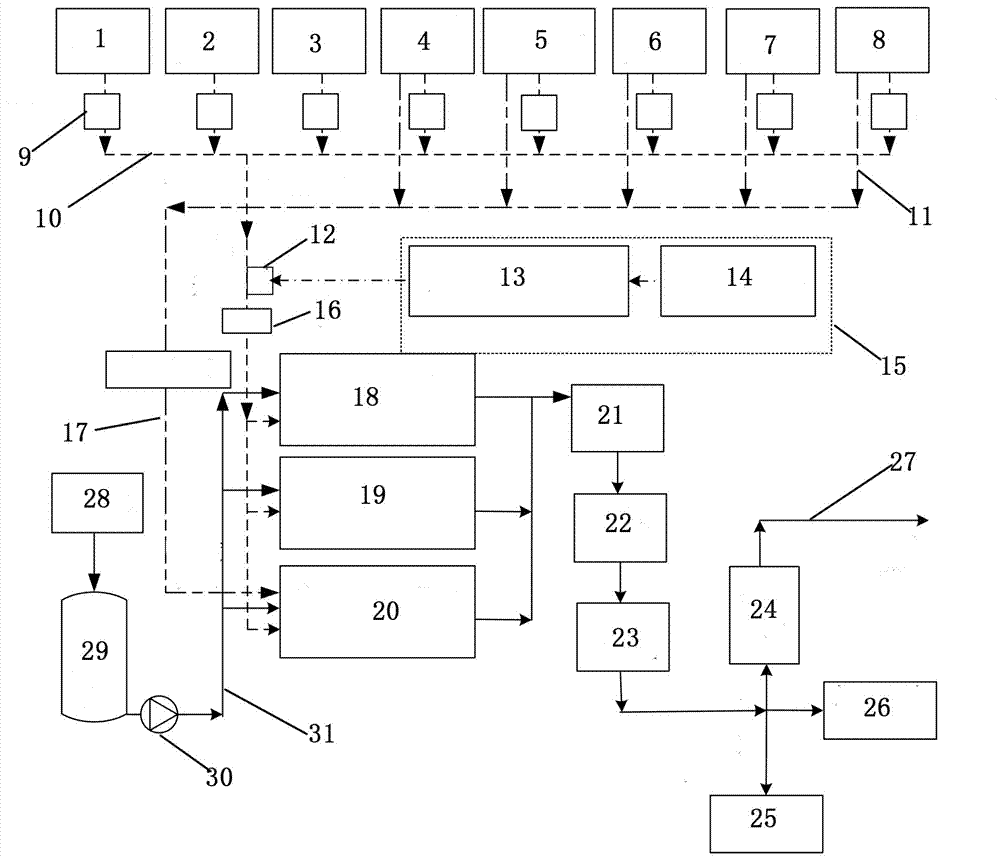

[0041] Such as figure 1 As shown, a system that uses clean energy to generate electrolytic hydrogen and injects it into the gas pipeline network, including a power grid dispatching peak-shaving control cloud platform 15, a clean energy power generation system, a high-voltage power grid 10 system, an electrolytic water hydrogen production system, pure water preparation and water replenishment System, hydrogen collection and purification and external transportation system, also includes electrolytic cell high-temperature steam supply system; the clean energy power generation system includes wind power plant 21, photovoltaic power plant, hydropower plant 3, biomass power plant 4, waste incineration power generation plant 5, nuclear power plant 6, gas-fired power plant 7, and clean coal power plant 8; the electrolytic water hydrogen production system includes an alkaline aqueous solution electrolytic hydrogen production device 18, a solid polymer electrolytic hydrogen production de...

Embodiment 2

[0070] Embodiment 2 is similar to Embodiment 1, except that the preferred electrolytic water hydrogen production system in this embodiment includes a plurality of alkaline aqueous solution electrolytic hydrogen production devices 18, and the alkaline aqueous solution electrolytic hydrogen production devices 18 include hydrogen Oxygen separation electrolyzer, hydrogen gas water separation tank, hydrogen system alkali addition tank, oxygen gas water separation tank, oxygen system alkali addition tank, electrolyte pipeline, hydrogen washing tank 21 and dehydration tank, oxygen washing tank. The hydrogen-oxygen separation electrolytic cell is composed of a cathode, an anode, a diaphragm and an electrolyte. The electrolytic cell uses carbon fiber materials and metal foam mesh as the substrate and electrode materials, such as carbon cloth, carbon paper, nickel foam, etc., to obtain a stable three-dimensional nanostructure to improve its catalytic efficiency, and the carbon fiber or n...

Embodiment 3

[0072] Embodiment 3 is similar to Embodiment 1, the difference is that the preferred electrolytic water hydrogen production system in this embodiment includes a plurality of high-temperature solid oxide electrolytic hydrogen production devices 20, and the water vapor consists of a main steam bypass 11, an electric superheater The high-temperature steam supply system supply of device, high-temperature steam delivery pipeline 17. The high-temperature solid oxide electrolytic hydrogen production device 20 includes a high-temperature solid oxide hydrogen-oxygen separation electrolyzer, a hydrogen scrubbing tank 21, a dehydration tank, and an oxygen scrubbing tank. The high-temperature solid oxide hydrogen-oxygen separation electrolyzer is a flat-plate SOEC electrolyzer, with a dense electrolyte layer in the middle and porous hydrogen electrodes and oxygen electrodes on both sides. The main function of the electrolyte layer is to separate oxygen and fuel gas, and to conduct oxygen. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com